ITEM # PART NO. DESCRIPTION QTY REQ’D Key/Ref Assy/Kit

25 09-200-3057 #10-32 X 1/2 FHCS Slotted (Pad) 4 S/K A-18

48 09-445-29747 1/4-20 x 1-1/4 SHCS w/patch (Foot) 4 S/K A-18

54 09-445-29758 1/4 Split Ring Lock Washer (Foot) 4 S/K A-18

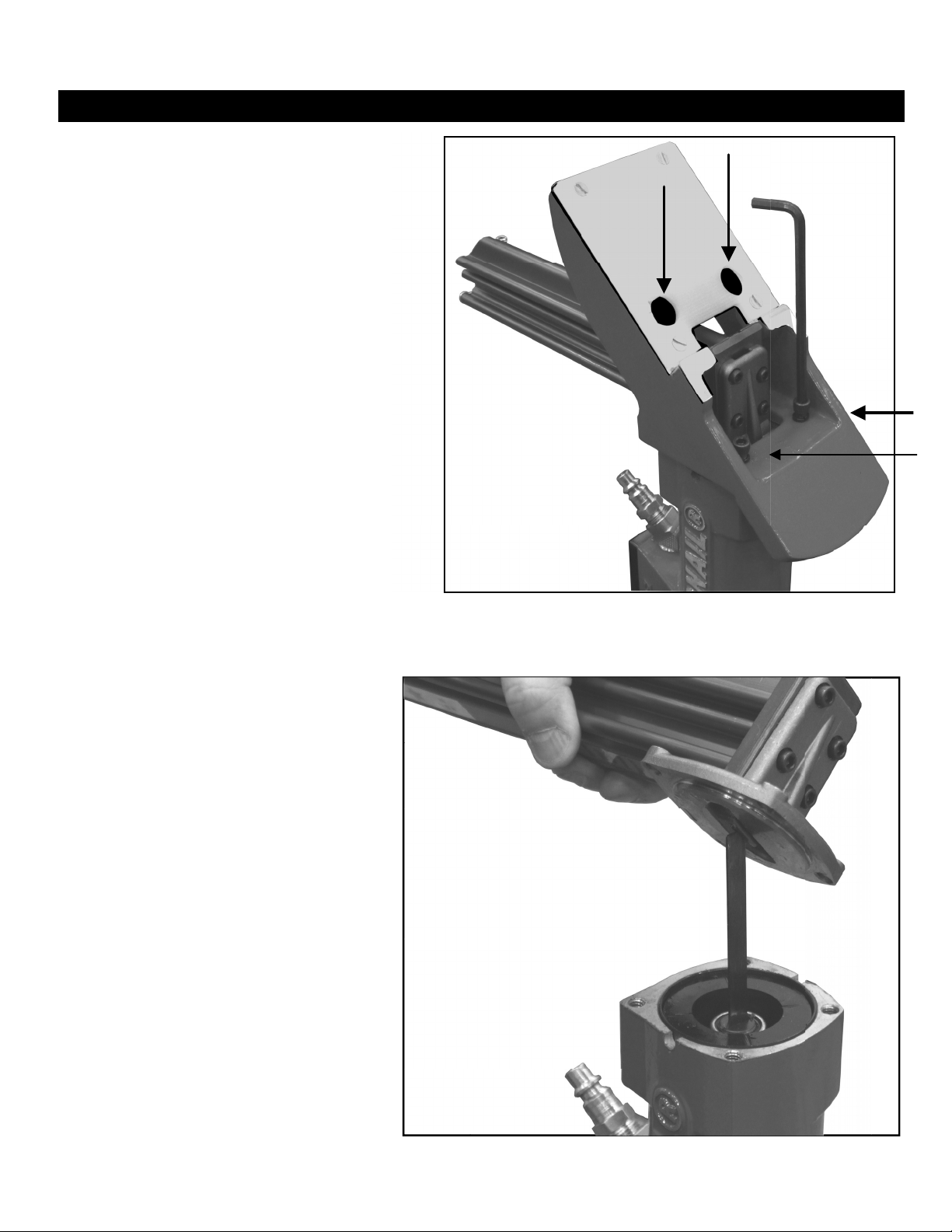

70 09-50P-3070 FLEX Foot 1 S/K A-18

71 09-50P-3071 FLEX Foot Bracket 1 S/K A-18

72 09-50P-3072 FLEX Foot Cam 1 S/K A-18

73 09-50P-3073 FLEX Foot Cam Plate 1 S/K A-18

74 09-50P-3074 FLEX Foot Pad 1 S/K A-18

75 09-50P-3075 SHCS 1/4-28 x 1.25" 2 S/K A-18

76 09-50P-3076 Washer .281 IDx.62 ODx.051" T 2 S/K A-18

77 09-50P-3077 BHCS #10-32 x .50" 2 S/K A-18

78 09-50P-3078 1/4 SH DIA x .50" SH. Bolt 1 S/K A-18

79 09-50P-3079 Belleville Disc Spring 1 S/K A-18

90 09-50P-3100 FLEX Adapter Foot (Tri-Glide) 1 S/K A-17, A-18

94 09-445-29801 FLEX 3/16" Allen Wrench 1 S/K A-18

105 09-50P3101A Plastic Triangle SET OF 2 (Plastic) 1 K A-17, A-18, A-19

106 09-50P3102 1/4"-20 x 3/4"L FHCS 2 S/K S, A-17, A-18

107 09-44529802 Hex Wrench 5/32" 1 S/K S, A-17, A-18

FLEX TRI-GLIDE PARTS LIST

KEY: S=Sold Separately, A= Sold as part of assembly, F=Factory replacement only, K=Sold as part of a Kit

ITEM PART NO. DESCRIPTION QTY

A-1 09-200-3058A Seal Kit (1 Each Of All Seals) 1

A-2 09-445-29759A Long Handle Assembly 1

A-3 09-445-29760A Short Handle Assembly 1

A-4 09-50P-3065A Nail Channel Assembly (Standard) 1

A-5 09-445-29824A Extra Long Handle Assembly 1

A-6 09-50P-3064A Driving Blade Assembly w/Rubber Seat 1

A-7 09-AW-445 Allen Wrench Set (3/16 & 5/32) 1

A-8 09-445-29757A 6 oz. Industrial Light Air Tool Oil 1

A-12 09-445-29768 Box Wrench (2) 2

TU 09-50P-TUKIT-R2 Tune-up Kit for all (R2) 50P, 50P FLEX, & 50P Power Rollers 1

A-14 09-50PFOOTKIT Steel foot assembly - includes R2 Foot, Gate, Gate Plate, screws 1

A-15 09-50P3050A Nail Pusher Assembly (Top Load) 1

A-16 09-50P3056A Nail Channel Assembly (Top Load) 1

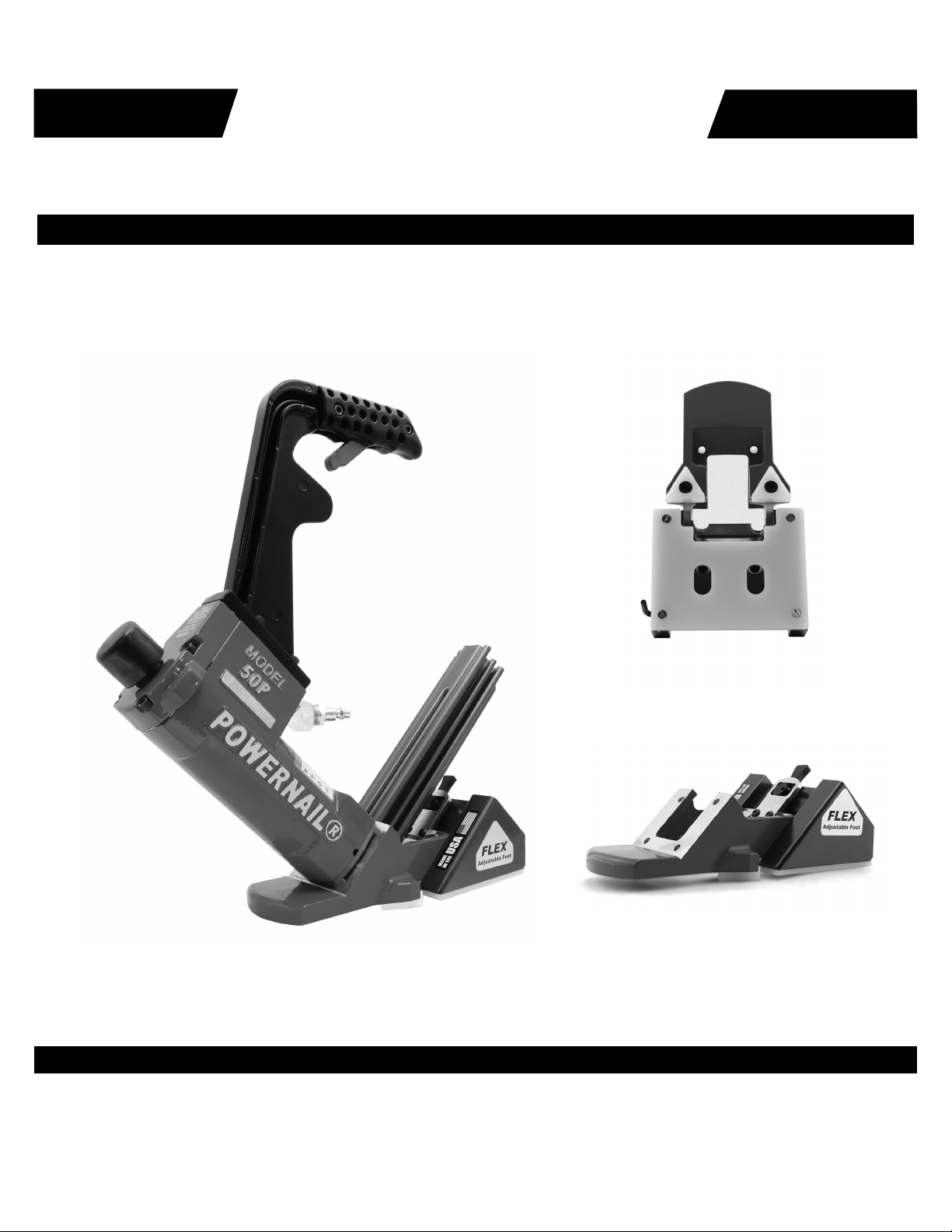

A-17 09-50P3100A FLEX Tri-Glide Adapter Foot Assembly 1

A-18 06-99600 FLEX Tri-Glide Conversion Kit 1

A-19 09-50P3101A FLEX Tri-Glide Plastic Triangles - SET OF 2 (Adapter Foot) 1

06-99601 Power Roller Conversion Kit 1

09-50P3107 Tri-Glide Triangle (Aluminium) 1

Powernail FLEX Assemblies, Kits and Accessories