VWR Clinical 100 User manual

Other VWR Laboratory Equipment manuals

VWR

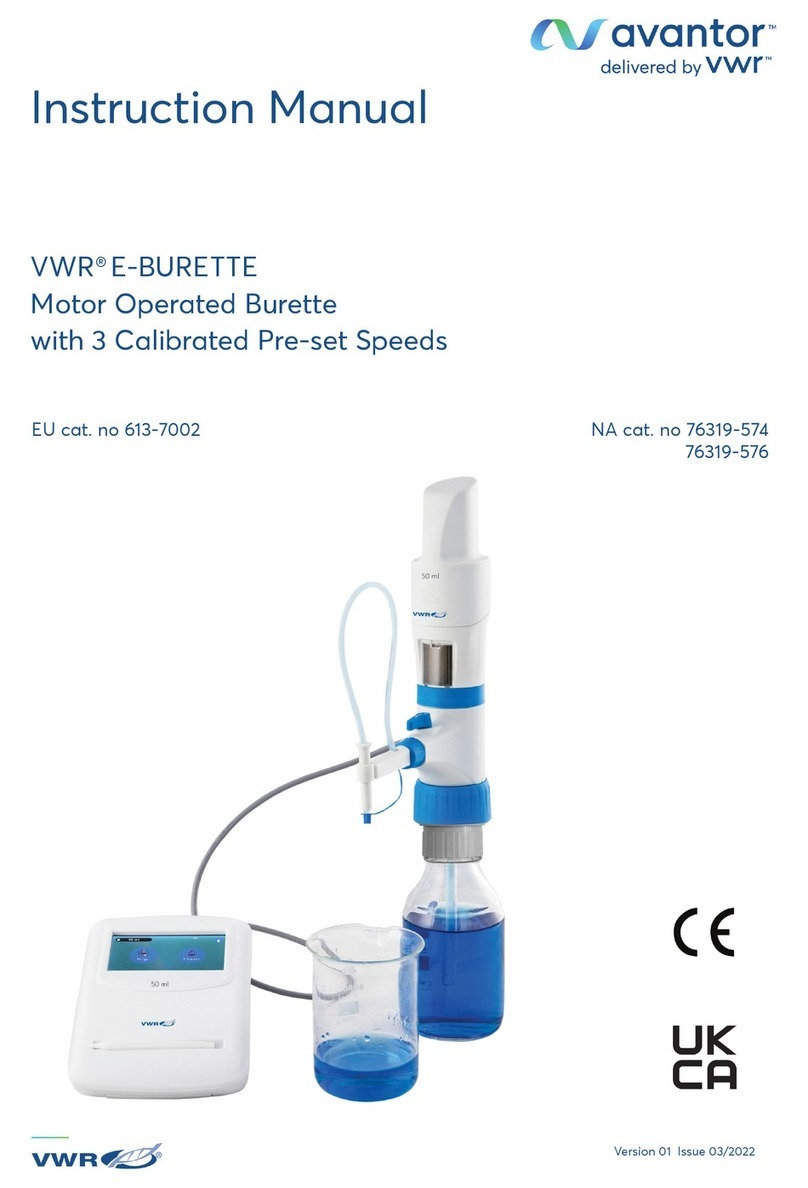

VWR AVANTOR E-BURETTE User manual

VWR

VWR Pinocchio Super Petri Validated User manual

VWR

VWR SAS Super IAQ User manual

VWR

VWR avantor 710-2088 User manual

VWR

VWR 5600 Series Operating instructions

VWR

VWR VAPOUR-Line eco 50 User manual

VWR

VWR Mini Shaker User manual

VWR

VWR HCO304 User manual

VWR

VWR 89209-862 User manual

VWR

VWR Powerpette Pro User manual

VWR

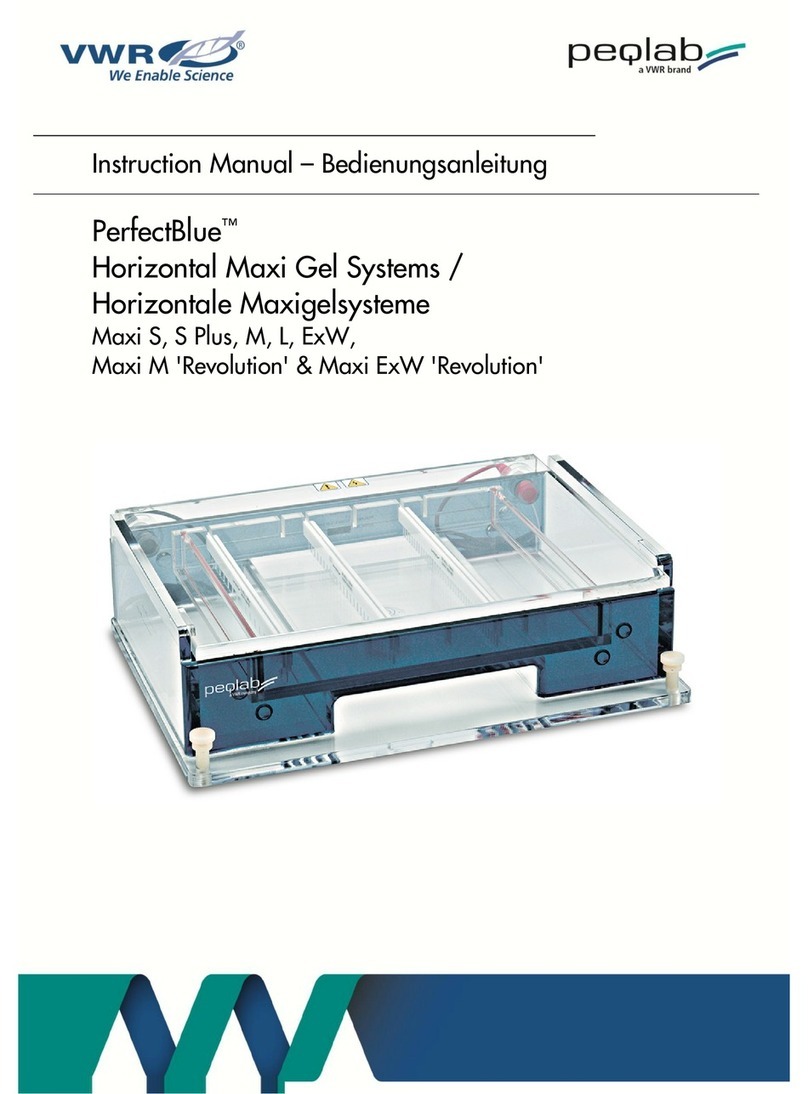

VWR PerfectBlue Maxi S User manual

VWR

VWR avantor 49893-2000 User manual

VWR

VWR INCU-Line IL 23R Cool User manual

VWR

VWR avantor MICRO STAR 30R User manual

VWR

VWR Photo Imager Guide

VWR

VWR Powerpette Pro User manual

VWR

VWR Professional Series User manual

VWR

VWR avantor Chemi Premium User manual

VWR

VWR VE2 User manual

VWR

VWR Micro Star 12 User manual

Popular Laboratory Equipment manuals by other brands

Agilent Technologies

Agilent Technologies 5800 ICP-OES user guide

Endress+Hauser

Endress+Hauser Cleanfit CPA875 operating instructions

NI

NI PXI-5422 CALIBRATION PROCEDURE

Collomix

Collomix Aqix operating instructions

SPEX SamplePrep

SPEX SamplePrep 6875 Freezer/Mill Series operating manual

Ocean Insight

Ocean Insight FLAME-NIR+ Installation and operation manual

Parker

Parker ALIGN-MG-NA Installation, operation and maintenance manual

BD

BD 644787 user guide

DENTAURUM

DENTAURUM Compact Megaplus Instructions for use

Biuged Laboratory Instruments

Biuged Laboratory Instruments BGD 626 instruction manual

illumina

illumina MiSeqDx reference guide

Yamato

Yamato BM510 instruction manual