Preferred TG-EL-D4B Series User manual

Instruction Manual SDI-TG-EL-D4B-xx-x-0 page 1 of 38 Revised 3/8/22

Preferred Utilities Manufacturing Corporation Firmware 1.06

FUEL SENTRY TANK GAUGE AND

LEAK DETECTION SYSTEM

Model TG-EL-D4B-xx-0-0

The TG-EL-D4B Tank Gauge/Fuel Management System with

Leak Detection System monitors one or two tanks. The D4B

tracks fuel deliveries and daily/weekly fuel consumption. It is a

powerful accounting tool. The leak-detection system is designed for

use with double wall tanks, vaulted tanks, single wall tanks with spill

basins, and double wall piping. The TG-EL-D4B is designed for use

with all fuel oils (No. 2 – No. 6), diesel, kerosene, jet fuel, and most

other petroleum products.

Features include:

Easy-to-read bar-graph touchscreen display

Printer option with automatic report printing

Automatic delivery report and data logging

Daily/weekly usage report and data logging

Daily HD-A2-C automatic leak sensor testing

Overfill alarm

Idle tank theft alarm

Eight Intrinsically Safe (I.S.) sensor inputs

RS485 and Ethernet Modbus

Fully field-configurable

D4B_Edit PC based configuration via USB

4-20 mA Xmtrs or switch sensors:

TG-EL-WF-x-C 4-20 mA wire float level sensor

TG-EL-HLT-x-C 4-20 mA head level sensor

Most other 4-20 mA level, head, bubbler, ultrasonic, or

magnetostrictive level sensors

HD-A2-C 4-20 mA discriminating leak sensor

RBS or PS-LDS float leak switch

Most other contact closure leak sensors

Table of Contents

SAFETY .................................................................................... 2

Specifications ............................................................................ 3

Ordering Information ................................................................. 3

Features .................................................................................... 4

Alarms & Status’s: ..................................................................... 5

Printer:....................................................................................... 6

Operation .................................................................................. 7

Menu Layout ............................................................................. 9

I/O Configuration Worksheet ................................................... 11

Physical Installation................................................................. 14

Wiring ...................................................................................... 15

Level Sensor Type Setup & "Stick Depth".............................. 20

Tank Dimensions and Stick Chart Types ................................ 22

Delivery Detection Setup ......................................................... 24

Theft Alarm Setup ................................................................... 25

Alarms and Status Functions Setup ........................................ 25

Printer ...................................................................................... 26

Troubleshooting & VIEW I/O ................................................. 26

Password ................................................................................ 28

Modbus ................................................................................... 29

Configuration Record .............................................................. 30

Panel Cutout Template ........................................................... 38

Instruction Manual SDI-TG-EL-D4B-xx-x-0 page 2 of 38 Revised 3/8/22

Preferred Utilities Manufacturing Corporation Firmware 1.06

SAFETY

WARNING

This product is intended for use in Commercial and Industrial installations,

it is NOT intended for Residential use.

This product is intended to be used by Trained Operators.

Installation, start-up, and troubleshooting is intended to be done by

Experienced Technicians familiar with Industrial Safety Codes

and installing devices in Hazardous Locations.

DANGER

Failure to comply with Control drawing 190789, and the instruction manuals of all Intrinsically

Safe sensors connected to the TG-EL-D4B, voids the Intrinsically Safe design and creates an

explosion risk in the hazardous area.

NOTE:

Do NOT begin to install or wire the TG-EL-D4B or the sensors unless the

TG-EL-D4B I/O Channel Configuration Worksheet has been completed and

all of the Intrinsic Safety wiring and physical installation notes have been read.

DANGER

Electric Shock Hazard

Multiple power sources may be present.

Disconnect all electric power sources, local and remote, before servicing

Instruction Manual SDI-TG-EL-D4B-xx-x-0 page 3 of 38 Revised 3/8/22

Preferred Utilities Manufacturing Corporation Firmware 1.06

Specifications

Inputs (15 total)

Analog: (8) 4-20 mA or contact closure

Each channel field-configured

Intrinsically Safe: Class 1, Zone 0, Group CD

Voc = 29.9, Isc= 99.5mA, Po= 0.75W

Resolution: 0.007%

Accuracy: 0.1%

Discrete: (2) 120 VAC, 13 mA

(5) 24 VDC, sinking, internal pull-up

Outputs (14 total)

Analog: (2) 4-20mA, 16 bit

650 ohms max, volume or depth

Relays: (4) SPST NO, 1.5A pilot, 120Vac

(2) SPDT, 10A 250Vac

Discrete: (6) 24 Vdc, 200mA, Sinking

Requires external power supply

Instrument

Input power: 120 VAC +/-15%, 50/60 Hz, 26 VA

Enclosure: Nema 12 Faceplate

Bezel: 3 7/8 w x 8 h x 1 d

Rear Case: 3 1/2 w x 7 9/16 h x 4 7/8 d

Panel Cutout: 3.61 w x 7.65 h

Ambient temp.: 32° to 131° F (0-55° C)

Display: Color Touch Screen

Communications

RS485: Modbus RTU, 4800-57600 baud

Ethernet: Modbus TCP

USB: for D4B_Edit config. Read/Write

Printer

Input power: 120 VAC +/-15%, 50/60 Hz, 20 VA

Size: 4.6"H x 4"W x 2.8"D

Enclosure: Nema 1

Ambient temp.: 32° to 122° F

Paper: 2.25" W, thermal, 30 columns

Ordering Information

Tank gauge

TG

-

EL

-

D4B

-

___

-

___

-

0

No enclosure, no printer 00

Wall-mount enclosure, no printer E0

Wall-mount enclosure, with printer EP

RS485 Modbus

0

Magnetostrictive Level Sensor…………..…………TG-EL-MSxx

Single Float, (1) 4-20mA

Magnetostrictive Level Sensor……………..TG-EL-MSxx-D420

Dual Floats, Fluid and Water levels, (2) 4-20mA

Wire float level sensor, 4-20 mA

(See TG-EL-WF for dimensional information.)

7-ft. max. depth ............................................. TG-EL-WF-7-C

12-ft. max. depth ........................................... TG-EL-WF-12-C

Submersible head level sensor, 4-20 mA

7-ft. max. depth, #2 oil and diesel ................ TG-EL-HLT-7-C

15-ft. max. depth, #2 oil and diesel .............. TG-EL-HLT-15-C

Leak sensor, dry/water/oil, 4-20mA

25-ft. sensor .......................................................... HD-A2-C

8-ft. sensor ......................................................... HD-A2-C-8

Sensor guard for HD-A2-C for sumps, vault floors,

bright areas ................................................................... HD-HSG

Leak sensor, float actuated, day tank, double wall pipe ...... RBS

Leak sensor, pump set leak float switch ........................ PS-LDS

Two-wire direct burial cable .............................................. 92612

(For use with TG-EL-WF-x-C, RBS, HLS.)

Four-wire vented direct burial cable .................................. 26000

(For use with TG-EL-HLT-x-C.)

Fil-A-Larm Station (120 V)………………A-AV-xD3-SS

Printer for panel mounting ....................... TG-EL-D4x-PRINTER

(Shipped loose for TG-EL-D4B-00-x-0 or TG-EL-D4B-E0-x-0.)

Windows configuration software (not equired)………..D4B_Edit

Instruction Manual SDI-TG-EL-D4B-xx-x-0 page 4 of 38 Revised 3/8/22

Preferred Utilities Manufacturing Corporation Firmware 1.06

Features

The TG-EL-D4B can monitor tank volume (gallons or liters) and tank leak detectors for one or two tanks via

8 Intrinsically Safe inputs.

Fully field-configurable: The TG-EL-D4B can be completely configured in the field from its touchscreen menus.

A laptop with D4B_Edit software can also be used to configure the D4B via the USB port.

Gallons (or liters) volume calculation based on:

a) One of five standard tank shapes with user-entered tank dimensions (inches or centimeters), or

b) A user-entered volume-vs.-depth stick chart (up to 51 points), typically from tank mfg. stick chart data.

The D4B can print a stick chart for either dimension-based or manual stick chart-based calculations.

Delivery detection and Data Logging: The TG-EL-D4B automatically detects a delivery and stores the delivered volume in a

time/date-stamped data-logger nonvolatile memory. The most recent 50 Deliveries are saved.

The printer can be configured to automatically print a time/date-stamped “Volume Delivered” report after each delivery that can be used

to verify the invoice before payment. The complete delivery history can also be viewed from the TG-EL-D4B screen, or read via USB into

D4B_Edit.

Usage monitoring and Data Logging: Every day at midnight, the TG-EL-D4B computes the usage for the previous day based on: tank

volume at the previous midnight, the sum of all deliveries during the day, and the tank volume at the current midnight. Usage less than

(0.1% of Full Tank volume) or (Idle Tank Volume Change Theft SP) is considered to be 0 usage for the day. This prevents nuisance

usage due to fluid thermal expansion/contraction.

The resulting daily usage is date-stamped and stored in the data-logger nonvolatile memory. Every Sunday at midnight, the previous

seven days are added together and stored as the weekly usage. The oldest data are overwritten by newer data. Usage data can be

printed, viewed via the touchscreen menus, or read by Modbus.

For a single-tank system, the D4B stores the last 70 days and the last 52 weeks usage for the tank.

For a dual-tank system, the D4B stores 70 total usage records, so typically 35 days and 26 weeks for each tank.

On Demand HD-A2-C Leak Detector Test: The user, or an inspector, can initiate an HD-A2-C test from the display menu. If the printer

option is installed a time/date stamped pass/fail report will be printed.

Daily Automatic HD-A2-C Leak Detector Testing and Data Logging: Every Day at midnight, all HD-A2-C Leak Detectors are

automatically tested. If any Fail, the Manual Reset Leak Alarm is activated. The last 70 pass/fail results for each HD-A2-C, and the

channel(s) that failed is stored in the data logger.

Flexible, multipurpose Intrinsically Safe (I.S.) inputs: Each of the eight I.S. input channels can be connected to either a two-wire 4-20

mA transmitter or a contact closure. A wide variety of ullage, depth, head, discriminating leak, leak switch, fill alarm level switch, fill alarm

silence PB switches and sensors can be field-configured from the TG-EL-D4B menus to be connected to any one of the eight I.S. input

channels.

Selection of a standard Preferred Utilities sensor also configures the 4-20mA engineering units. Other I.S. 4-20 mA transmitters can also

be used with manually entered 4-20mA engineering units.

RS485 and Ethernet Modbus: The current depths, volumes, alarms, and statuses can be read via Modbus. The previous day delivery

and usage data can be read via Modbus. See the table at the end of the manual for Modbus addresses.

Custom Names: The touchscreen allows the user to enter a 12 character Name for each of the 15 Inputs. Each Tank also has a user

entered Name. These Custom Names appear on all Operator screens, Alarms, and Alarm History screens.

However, the Configuration/Setup menus used during installation the TG-EL-D4B refer to “Tank A” and “Tank B”.

Instruction Manual SDI-TG-EL-D4B-xx-x-0 page 5 of 38 Revised 3/8/22

Preferred Utilities Manufacturing Corporation Firmware 1.06

Alarms & Status’s:

The TG-EL-D4B can be configured to generate a wide variety of alarms. Alarms are time and date-stamped and then stored in the

data-logger nonvolatile memory. The alarm history can be printed, viewed on the touchscreen, or read into D4B_Edit PC software. The

TG-EL-D4B stores the last 50 alarms and events.

Over Fill alarms (FILALM x and OFIL-LK C): Typically an outdoor bell and light (FA-AV-xD3, or equal) are installed near the tank fill

pipe to warn the driver to stop filling the tank before it overfills.

For each tank, any, or all, of these signals/sensors can affect the outdoor bell:

Level Sensor HI Volume Setpoint (HI SP) TG-EL-WF, TG-EL-HLT, or other 4-20mA level sensor

Level Sensor HIHI Volume Setpoint (HIHI SP) TG-EL-WF, TG-EL-HLT, or other 4-20mA level sensor

Tank high level float switch (FILALM LS) HLS, PLS, or other float switch

Vent Pipe float switch (VENT LS) RBS, or other float switch

Leak Sensor (LK HD-A2, LK CONTAC) HD-A2-C, RBS, HLS, PS-LDS, or other

The FILALM x output rings the outdoor bell when: HIHI SP is exceeded, or FILALM LS or VENT LS is active.

The OFIL-LK C output rings the outdoor bell when: HI SP or HIHI SP is exceeded, or FILALM LS, VENT LS, or any Leak Sensor

(HD-A2-C or LK CONTAC) is active for either tank.

The outdoor FilAlarm bell can be silenced by the driver if an outdoor pushbutton is wired to an FILALM AS input, or it will automatically

silence after 60 seconds (adj. 10-120 sec.). Before filling the tank, the driver can test the fill alarm by pressing and holding the outdoor

alarm silence button for more than five seconds.

The FilAlarm output (bell) will re-activate every time any of the related signals activates.

FILALM x output example: Volume > HIHI SP, bell sounds, bell silences (Driver or Auto Silence), tank keeps filling, FILALM LS tank level

switch activates, bell sounds, bell silences, tank keeps filling, VENT LS vent pipe switch activates, bell sounds. The OFIL-LK output

responds similarly, but for more sensors.

The Outdoor light is typically activated by the HIHI x ST output, which energizes if Volume > HIHI SP, FILALM LS, or VENT LS is active.

For dual-tank systems, individual (or common) lights, bells, alarm silence buttons and/or bells can be used, provided enough outputs are

available.

Overfill Alarms do not trigger the D4B local alarm beeper or ALARM COM output, and are not recorded in the Alarm History. However, HI

and HIHI Volume alarms are data logged.

Theft alarm: Thefts are monitored in two ways: idle tank volume change and high usage rate.

Idle tank: An idle tank will trigger a theft alarm if the volume drops an adjustable amount below the volume saved at the time the tank

became idle. This mode requires a contact closure input that indicates when the tank is idle. This could be a manual valve auxiliary

switch, a pump starter auxiliary switch, a flow switch, a diesel generator “not running” contact, or other means.

High usage: The D4B monitors the tank volume every few minutes and calculates a short-term usage rate. If this rate is higher than a

user-adjustable theft rate, a theft alarm will be triggered. This strategy assumes that the normal peak flow rate is known and that the theft

is caused by a high flow rate removal of oil by a pump.

Instruction Manual SDI-TG-EL-D4B-xx-x-0 page 6 of 38 Revised 3/8/22

Preferred Utilities Manufacturing Corporation Firmware 1.06

Other Alarm and status functions: In addition to the fill alarm, theft alarm, and leak alarms discussed above, each tank has four

volume-based alarm functions, four volume-based status functions, and two volume-based control functions.

Alarm and status functions are very similar. Status functions do not trigger the alarm outputs.

Almost all alarms reset/silence automatically when the condition clears. A Leak alarm will stay in alarm until the the Leak signal returns

to normal and is then Reset by the Operator. The Low-Low level alarm can be configured as either manual reset or auto reset. The

ALARM COM output can be silenced either from the faceplate Alarm Silence button, or from a COMMON AS input from an external

pushbutton.

There are four user-adjustable volume setpoints for each Tank (total of eight), and one alarm delay seconds parameter:

HIGH-HIGH, HIGH, LOW, LOW-LOW

Each setpoint is used by both an alarm function and a status function, and sometimes by other functions.

The setpoint name describes the logic, examples:

HIGH-HIGH setpoint: If the volume is higher than the HIGH-HIGH setpoint for more than the alarm delay seconds, outputs configured as

either HIHI x AL or HIHI x ST are triggered.

LOW setpoint: If the volume is lower than the LOW setpoint, LO x AL and LO x ST outputs are triggered.

Other setpoint uses:

The HIGH-HIGH setpoint triggers the Fill Alarm function described above.

FILL function: If volume < LOW setpoint, FILL turns ON. If volume > HIGH setpoint, FILL turns OFF.

If both conditions are true, FILL turns OFF.

DRAIN function: If volume > HIGH setpoint, DRAIN turns ON. If volume < LOW setpoint, DRAIN turns OFF.

If both conditions are true, DRAIN turns ON.

Any Alarm or Status can energize any output. The user configures each output to respond to the desired Alarm or Status. Multiple

outputs can be configured to respond to the same Alarm or Status. See the ROUT/DOUT CONFIG menu.

Printer:

The TG-EL-D4B-EP-0-0 includes a printer and is pre-mounted in a wall mount enclosure.

The TG-EL-00-0-0 and TG-EL-E0-0-0 does not include a printer. The TG-EL-D4A-PRINTER can be purchased separately, mounted in a

user provided enclosure.

The following printed reports are provided:

Short report includes for each tank: current depth and volume; previous day’s usage; last delivery and the

most recent HD-A2 test result; and the last 10 alarms.

Long report includes everything on the short report, plus: the 10 latest deliveries for each tank, the last 8 daily consumptions for

each tank, and the last 5 weekly consumptions for each tank.

Stick Chart report shows the volume at various depth intervals, one tank per report (maximum of 50 evenly spaced depths, plus the

full volume and depth).

Any of the above reports can be printed at any time by the operator via the touchscreen PRINT button if the printer option is enabled.

In addition, reports can be configured to automatically print based on the following events:

Every Midnight: Disable, Short Report, Long Report

Every Sunday Midnight: Disable, Long Report

After Any Alarm: Disable, Short Report

After a Delivery: Disable, Long Report

If the printer is not installed, all data logged data can also be extracted with the D4B_Edit Windows PC App for viewing and saved in a

.csv format for easy integration into a spreadsheet.

Instruction Manual SDI-TG-EL-D4B-xx-x-0 page 7 of 38 Revised 3/8/22

Preferred Utilities Manufacturing Corporation Firmware 1.06

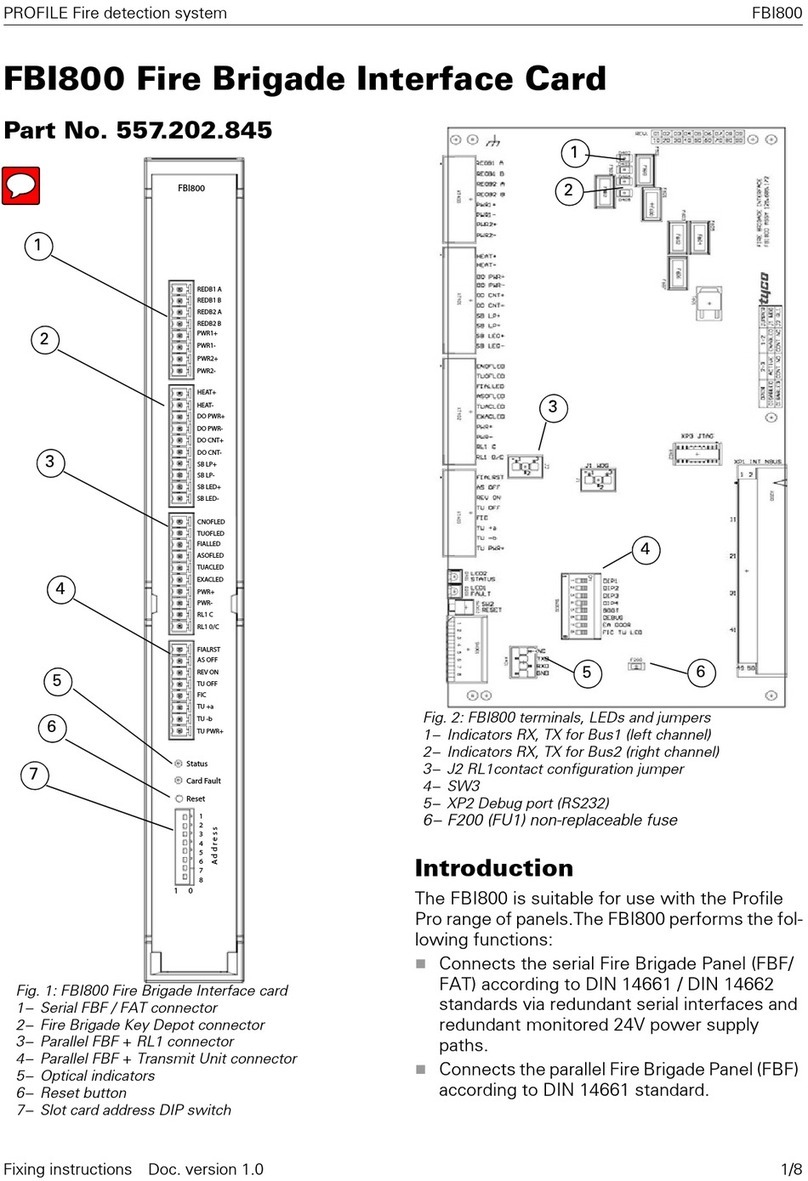

Operation

The main screen displays the tank volume and fluid depth

(gallons and inches, or liters and centimeters). With volume being

displayed above the depth measurement.

There are three Home screens: Tank A only, Tank B only, Tank A & B.

If the TG-EL-D4B is configured to monitor 2 tanks, press the right or left

arrow button to change main screens.

Tick marks on right hand side of the bargraph indicate level alarm

setpoints.

If a dual float level xmtr is installed the water depth in the bottom of the tank

is displayed to the left of the bargraph.

When an alarm occurs, the bargraph(s) will blink, and the Silence button

will blink. Depending on how the D4B is configured in the field, an alarm

can cause an external alarm bell or horn to activate.

Press the Silence button to stop the blinking and silence the external

bell/horn.

After Silencing, if any Alarms are still active, the Alarms button appears.

Press the Alarms button to display the Active Alarms screen.

The Reset button appears if any alarms require a Manual Reset. Reset will

only reset an alarm if if has Cleared (ie returned to normal).

Press History to display the History screen.

The History screen displays the Time/Date of the most recent 50 Alarms

and Events.

Touch the Up or Down arrow to advance to the next page of History. Touch

Date to enter a time/date in order to jump to the nearest History record.

The Hide Events and Show Events removes or displays Events.

The History memory is retained when powered down. The History can be

extracted via the USB port using the free D4B_Edit Windows App.

Reset

Silence Menu

History

Alarms

Home

Tank 2 High High Alarm

4608 Gallons ALARM 02:23:59

12/15

Tank 2 High Alarm

3991 Gallons ALARM 02:23:48

12/15

Tank 1 Low Low Alarm

2431 Gallons RESET REQ’d 02:22:57

12/15

Tank 1 Low Alarm

2860 Gallons ALARM 02:22:36

12/15

CH2 Leak Alarm

RESET REQ’d 02:19:06

12/15

Active Alarms

CH2 Leak Alarm

CLEAR 02:45:51

12/15

CH2 Leak Alarm

ALARM 02:45:51

12/15

CH2 Leak Alarm

CLEAR 02:45:46

12/15

Tank 1 Low Low Alarm

3683 Gallons CLEAR 02:41:26

12/15

Tank 2 High Alarm

4293 Gallons CLEAR 02:41:25

12/15

Tank 2 High High Alarm

4609 Gallons CLEAR 02:41:21

12/15

SILENCE

History Date

BackAlarms Home

Hide

Events

Show

Events

SILENCE MENU

Tank 1 Delivery In Progress

0.0

Full:

8000.0

Tank 1 Volume IN-GALLON

5615

HISTORY

ALARMS

49.7

0.0

Tank 2 Volume IN-GALLON

4121

36.5

Full:

8000.0

Water

3.6

Water

1.4

SILENCE MENU

Tank 1 Delivery In Progress

0.0

Full:

8000.0

Tank 1 Volume IN-GALLON

5615

HISTORY

ALARMS

49.7

Water

3.6

Instruction Manual SDI-TG-EL-D4B-xx-x-0 page 8 of 38 Revised 3/8/22

Preferred Utilities Manufacturing Corporation Firmware 1.06

History, HD-A2 leak test, and setting the clock:

The main menu is used to display these features.

See the complete menu layout in the next section for other features and information.

Menu operation:

From the operator home screens, press MENU.

This will bring up the Main Menu options.

History: Daily usage, weekly usage, deliveries, and alarms

From the main screen:

Press MENU.

TANK MAIN MENU appears.

Press Usage/Deliv. History

HISTORY submenu appears.

Daily Usage, Weekly Usage, and Delivery Histories can be selected.

A specific datsa can be entered and searched in any of the history screens.

Power outages can affect usage data:

Daily and weekly usage data are calculated at midnight. Power outage

scenarios include:

After power is restored: Usage is calculated from when power came back

ON until the next midnight.

Power off at midnight: Usage is not calculated, and 0 is recorded in all

“missed” days upon power up.

Power off Sunday midnight: Weekly usage is not calculated.

TEST HD-A2 (leak sensors):

The TG-EL-D4B tests all installed HD-A2 leak sensors that are not in alarm every midnight. Selecting the TEST HD-A2s item in the main

menu starts an HD-A2 test sequence and allows the user to witness the test.

Setting the clock time and date:

If the power is off for more than 10 days, or when the Daylight Saving Time shift occurs, the user will have to manually adjust the time,

date, and day of week for the clock.

From the main menu, select Utilities > Set Clock. Time is set in 24-hour format.

Use the Utilites Menu to access the touch calibration and cleaning screens, as well as the screen settings.

CAUTION: Changing the date can cause the data-logger usage memory to be erased in some circumstances. It will not affect any of the

TG-EL-D4B configuration parameters.

Password:

The TG-EL-D4B has an optional password system. Passwords are disabled when the TG-EL-D4B is shipped. To enable a password

press “Change Tech Password” on the Password Menu Screen. This allows the user to enter the desired password. Valid passwords are

numeric only and can be anything between -32768 to +32768. Once a password is set, the user must be logged in to change the

password again. Setting the password to 9999 disables the password system on the controller.

When the password system is activated and the D4B is logged out:

Reports can be printed.

The main display tank can be selected.

Alarms can be silenced.

All submenus and menu items can be displayed.

The clock can be set.

An HD-A2 test can be started.

No other items can be changed within the menu system.

When a password is entered, it automatically logs out after one hour.

Daily Usage History

Tank 2

12/22 1218

Tank 1

12/22 2725

Tank 2

12/21 471

Tank 1

12/21 757

Tank 2

12/20 0

Tank 1

12/20 0

SILENCE

Date

BackAlarms Home

Delivery History

Tank 1

1/26 08:17:07 1306

Tank 2

1/23 13:22:13 2803

Tank 1

1/23 13:22:45 1311

Tank 1

1/14 17:39:16 5109

Tank 1

12/30 17:38:02 1985

Tank 2

12/23 00:15:19 1604

SILENCE

Date

BackAlarms Home

Instruction Manual SDI-TG-EL-D4B-xx-x-0 page 9 of 38 Revised 3/8/22

Preferred Utilities Manufacturing Corporation Firmware 1.06

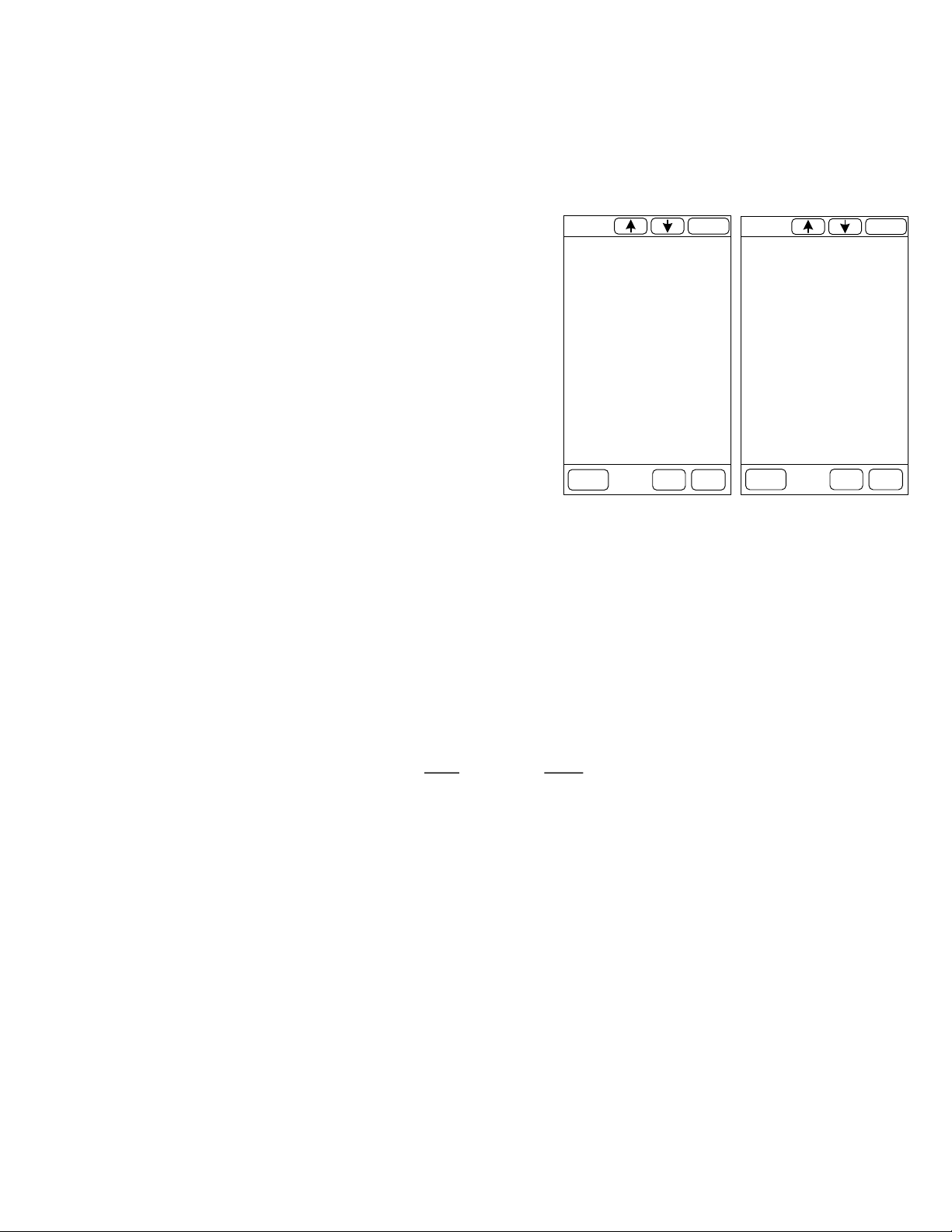

Menu Layout

Main Menu

Usage/Deliv. History

Test HDA2's

Utilities

Password

Configure/Setup

Communication Setup

View I/O

Ch. x AOUT

Function

Ch. x ROUT/DOUT

Function

Ch. x DIN

DIN CH Tank Select

DIN Name

DIN Sensor Type

NO / NC

Ch. x I.S. AIN

AIN CH Tank Select

AIN Name

AIN Sensor Type

Input at 4 mA

Input at 20mA

Depth Adjust

NO / NC

Configure I/O

Ch. 1-8 I.S. AIN

Ch. 9-15 DIN

Ch. 1-12 ROUT/DOUT

Ch. 1-2 AOUT

Alarm Delays

Alarm Delay Seconds

FillAlarm Auto Silence

Printer

Printer Option

Print at Midnight

Print After Delivery

Print After Alarm

Print Sunday Week Rpt

Communication Setup

Modbus RTU RS485

Modbus TCP Ethernet

Utilities

Set Clock

Calibrate Touch

Clean Screen

Screen Settings

Firmware Version

Startup History

Pasword

Enter

Change

Logout

Screen Settings

Brightness

Touch Buzzer

Alarm Buzzer

Tank A & B Configuration

Menus on Next Page

Configure/Setup

System Setup

Inputs/Outputs

Tank A

Tank B

Alarm Time Delays

Printer

System Setup

Unit Name

Location Name

Number of Tanks

Tank Units

Usage/Delivery History

Daily Usage

Weekly Usage

Deliveries

View I/O

Discrete I/O

Analog I/O

Instruction Manual SDI-TG-EL-D4B-xx-x-0 page 10 of 38 Revised 3/8/22

Preferred Utilities Manufacturing Corporation Firmware 1.06

Configure Tank A

Tank Name

Tank Shape and Size

High Alarms

Low Alarms

Theft Alarm

Deliveries Tank A Low Alarms

Low-Low Setpoint

Low-Low Mode

Low Setpoint

Low Enable

Tank A Theft Alarm

Theft Alarm Enable

Idle Volume Change SP

gpm / lpm Theft SP

Flat Horiz or

Dished End

H Obround or

V Obround

LinVert

Manual

Stick Chart

Tank A Stick Chart

Full Depth

Full Volume

Depth

Gallons

Tank A Data

Full Depth

Full Volume

Specific Gravity

Striker Plate Thickness

Tank A Data

Obround Width

Overall Length

Obround Height

Specific Gravity

Parallel Tank Qty

Striker Plate Thickness

Tank A Data

Tank Diameter

Overall Length

Straight Length

Specific Gravity

Striker Plate Thickness

Tank A Data

Full Depth

Full Volume

Specific Gravity

Depth Interval

Edit Stick Chart

Striker Plate Thickness

Tank A High Alarms

High-High Setpoint

High-High Enable

High Setpoint

High Enable

High Water Setpoint

High Water Enable

Tank A Deliveries

Tank A Delivery-Usage

Tank A Delivery Start Vol

Tank A Settling Seconds

Tank A Sizing

Stick Chart Type

Tank Data

Computed Full Volume

Instruction Manual SDI-TG-EL-D4B-xx-x-0 page 11 of 38 Revised 3/8/22

Preferred Utilities Manufacturing Corporation Firmware 1.06

I/O Configuration Worksheet

For each input channel, the user must enter: sensor name, sensor type, the tank the sensor is associated with, the sensor option, and possibly the sensor calibration data. Functions must

be assigned to the 4-20 outputs and the output outputs. Read all feature descriptions before completing.

The table and notes below detail the allowable configuration settings and the restrictions for each sensor type.

Allowable INPUT CONFIG settings for each SENSOR TYPE:

SENSOR TYPE

Description

Allowed

qty. per

tank

Allowed

tanks

Allowed

INPUT

CHANNELS

Contact NO / NC

Default

20 mA Cal.

Default

4 mA Cal.

LVL WF7

Level sensor, 7 ft., TG

-

EL

-

WF

-

7

-

C

note 1

A

,

B

IS AIN

1

-

8

84.0 ullage

0.0

LVL WF12

Level sensor, 12 ft., TG

-

EL

-

WF

-

12

-

C

note 1

A,B

IS AIN 1

-

8

144.0 ullage

0.0

LVL UL18

Level sensor, 18 ft, TG

-

EL

-

ULT

-

18

-

C

note 1

A,B

IS AIN 1

-

8

216.0 ullage

0.0

LVL OTHER

Level sensor, other 4

-

20 mA

note 1

A,B

IS AIN 1

-

8

100.0 depth

0.0

HEAD HL7

Head level sensor, 7 ft.,TG

-

EL

-

HLT

-

7

-

C

note 1

A,B

IS AIN 1

-

8

80.0" of water

n/a

HEAD HL15

Head level sensor, 15 ft.,TG

-

EL

-

HLT

-

15

-

C

note 1

A,B

IS AIN 1

-

8

160.0" of water

n/a

HEADOTHER

Head level sensor, other 4

-

20 mA

note 1

A,B

IS AIN 1

-

8

100.0" of water

n/a

LK HD

-

A2

Leak sensor, HD

-

A2

-

C, dry/oil/water discriminating

6

A,B,C

IS

AIN 1

-

8

n/a

n/a

LK CONTAC

Leak sensor, switch contact

6

A,B,C

IS AIN 1

-

8

N.C. or N.O.

n/a

n/a

FILALM LS

Tank Overfill alarm high

-

high level switch

1

A,B

IS AIN 1

-

8

N.C. or N.O.

n/a

n/a

VENT LS

Vent Pipe Overfill alarm high

-

high level switch

1

A,B

IS AIN 1

-

8

N.C. or N.O.

n/a

n/a

FILALM AS

Fill alarm remote alarm silence

1

A,B,C

IS AIN 1

-

8

N.C. or N.O.

n/a

n/a

FILALM AS

Fill alarm remote alarm silence

1, note 1

A,B,C

xx DIN 1

-

5

N.C. or N.O.

n/a

n/a

IDLE TANK

Idle tank theft alarm enable

1

A,B

xx DIN 1

-

5

N.C. or N.O.

n/a

n/a

COMMON AS

Common alarm, alarm silence contact

note 1

C

xx DIN 1

-

5

N.C. or N.O.

n/a

n/a

Notes: 1) Allowed qty. per tank:

FILALM AS: Either one per tank or one common, but not all three.

COMMON AS: Only one per system.

2) Allowed tanks: A = Tank A; B = Tank B; C = common area or piping (not related to a specific tank).

3) Contact input SENSOR OPTION:

N.C.: Normally closed contact. Contact opens when sensor activates.

N.O.: Normally open contact. Contact closes when sensor activates.

Instruction Manual SDI-TG-EL-D4B-xx-x-0 page 12 of 38 Revised 3/8/22

Preferred Utilities Manufacturing Corporation Firmware 1.06

TG-EL-D4B I/O Configuration Worksheet (continued)

Intrinsically Safe Analog Inputs (IS AIN)

Discrete (On/Off) Inputs (AC DIN and DC DIN)

Instruction Manual SDI-TG-EL-D4B-xx-x-0 page 13 of 38 Revised 3/8/22

Preferred Utilities Manufacturing Corporation Firmware 1.06

TG-EL-D4B I/O Channel Configuration Worksheet (continued)

4-20 mA Outputs AOUT Configuration: 4-20 mA Output Functions: X = A or B (Tank A or Tank B)

DISABLED Not used

TX VOL Tank X volume 20 mA = full volume

TX LVL Tank X level (fluid depth) 20 mA = tank diameter/full height/full depth

Relay Outputs ROUT Configuration: Relay and Discrete Output Functions: or Common to Both Tanks)

Discrete Outputs DOUT Configuration:

Ch. NO C NC Function

1123

2456

39 13

410 13

511 13

612 13

Terminals

Name:

Tank

Description:

Reset:

ALARM COM

Common alarm, with alarm local or remote alarm silence

Auto

LEAK COM

Combined Tank A or B or common

-

area leak alarm

Manual

LEAK

X

A,B

Tank

X

leak alarm

Manual

LEAK OTHR

Common

-

area leak alarm

Manual

FILLALM

X

A,B,C

OverFill alarm, Tank

X

(HIHI SP or FILALM LS or VENT LS

Auto

THEFT

X

A,B

Tank

X

theft alarm

Manual

HIHI

X

AL

A,B

Tank

X

high

-

high

-

volume alarm

Auto

HI

X

AL

A,B

Tank

X

high

-

volume alarm

Auto

LO

X

AL

A,B,C

Tank

X

low

-

volume alarm

Auto

LOLO

X

AL

A,B,C

Tank

X

low

-

low

-

volume alarm

Auto or

Manual

HIHI

X

ST

A,B

Tank

X

high

-

high

-

volume status.

Auto

HI

X

ST

A,B

Tank

X

high

-

volume status.

Auto

LO

X

ST

A,B

Tank

X

low

-

volume status

Auto

LOLO

X

ST

A,B

Tank

X

low

-

low

-

volume status

Auto

FILL X A,B Tank X fill valve/pump

Activates when volume drops below "Low" setpoint

Deactivates when volume rises above "High" setpoint

Auto

DRAIN

X

A,B

Tank

X

drain valve/pump

Activates when volume rises above "High" setpoint

Deactivates when volume drops below "Low" setpoint

Auto

OFIL

-

LK C

C

Combined FILLALM or HI SP or any Leak Alarm

Auto

Ch. +

-Function

140

39

242

41

Terminals

Instruction Manual SDI-TG-EL-D4B-xx-x-0 page 14 of 38 Revised 3/8/22

Preferred Utilities Manufacturing Corporation Firmware 1.06

Physical Installation

WARNING

Failure to comply with Control drawing 190789, and the instruction

manuals of all Intrinsically Safe sensors connected to the TG-EL-D4B,

voids the Intrinsically Safe design and creates an explosion risk in

the hazardous area.

TG-EL-D4B-00-x-x is designed for flush mounting in an enclosure.

TG-EL-D4B-Ex-x-x is pre-mounted in an enclosure.

The TG-EL-D4B should be mounted in a non-hazardous, indoor, NEMA 12

location that is free from excessive vibration. It is rated for continuous operation

over the 32º F-122º F (0º C-50º C) range.

The optional printer is rated NEMA 1 and should not be exposed to mists or

sprays.

Read all of the Intrinsic Safety (I.S.) requirements on drawing 190789 and in the

Wiring section before mounting the TG-EL-D4B.

The Intrinsically Safe wiring must remain physically separated from all other

non-Intrinsically Safe wiring by means of conduit, raceways, partitions, or tie-downs.

Tie-downs are acceptable if a 2" minimum separation is permanently maintained.

The I.S.-vs.-non-I.S. separation must be maintained both inside the panel that the

TG-EL-D4B is mounted in and outside the panel, all the way to the tank sensors.

See the sketches below for conduit entry locations and internal wire routing paths that will maintain the 2" minimum separation between

I.S. and Non-I.S. wiring.

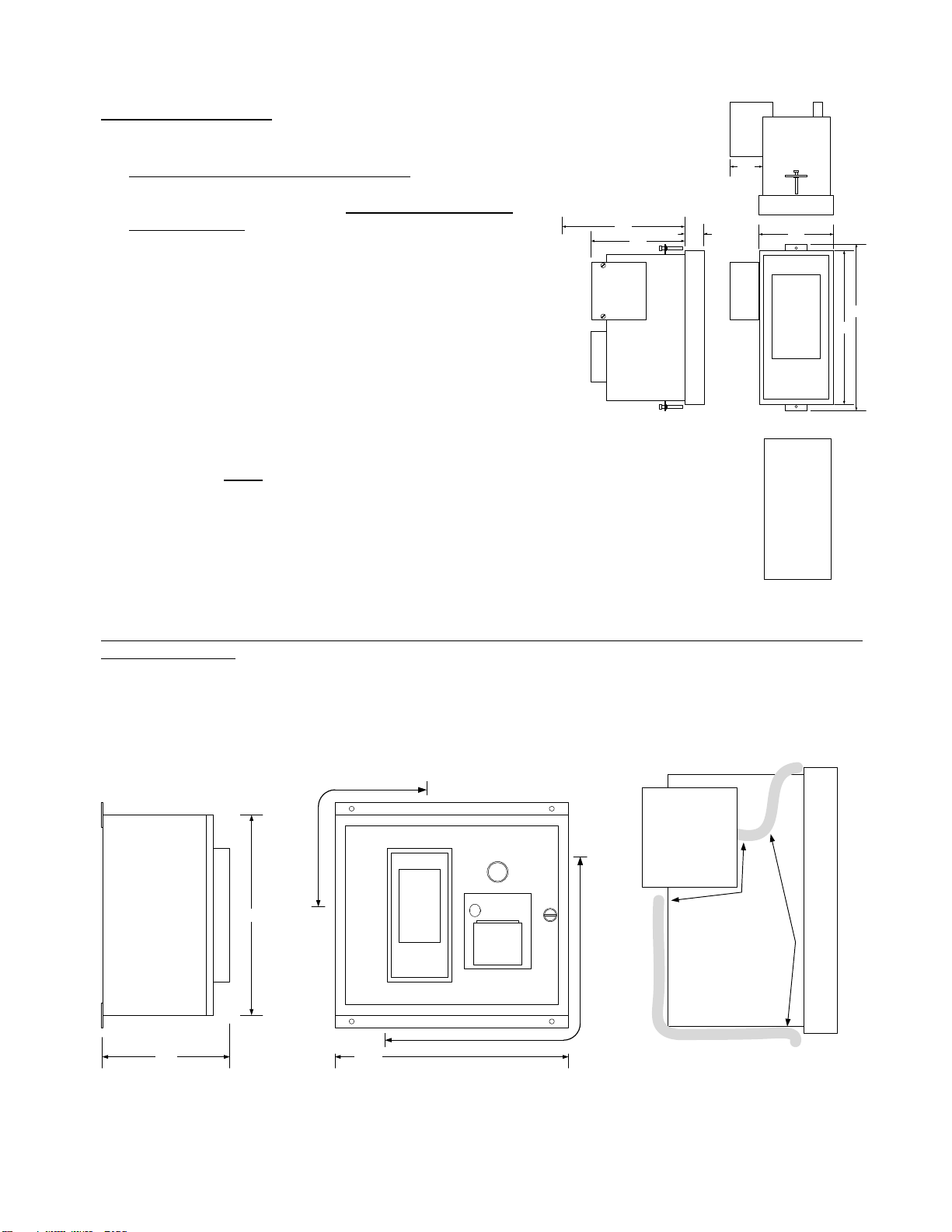

TG-EL-D4B-EP-x-x Dimensions

Conduit Entry

Internal Field Wiring

Locations Routing

3.88

8.00

Touch

Screen 8.74

1.70

Plug-in Terminals

Removable Cover

for

Intrinsically Safe

Terminals

1.00

4.88

6.38

Clearance If an Ethernet Cable is used

Panel Cutout

3.61 x 7.62

Non-Intrinsically Safe

Wiring Routing

Intrinsically Safe (I.S.)

Wiring Routing

Removable

Cover for

Intrinsically Safe

Terminals

Maintain at least 2"

separation between all

I.S and all non-I.S. wiring.

Use tie-wraps, hold downs,

or wiring duct to prevent

movement of wires.

Touch

Screen

Intrinsically Safe

Conduit Locations

Non - Intrinsically Safe

Conduit Locations

14.00

12.00

7.65

Instruction Manual SDI-TG-EL-D4B-xx-x-0 page 15 of 38 Revised 3/8/22

Preferred Utilities Manufacturing Corporation Firmware 1.06

Wiring

NOTE:

Do NOT begin to wire the TG-EL-D4B or the sensors unless the

TG-EL-D4B I/O Channel Configuration Worksheet has been completed and

all of the Intrinsic Safety wiring and physical installation notes have been read.

WARNING

Failure to comply with Control drawing 190789, and the instruction manuals of all Intrinsically

Safe sensors connected to the TG-EL-D4B, voids the Intrinsically Safe design and creates an

explosion risk in the hazardous area.

Intrinsically Safe wiring notes:

What is “Intrinsic Safety”? "Intrinsically Safe" (I.S.) means that when the TG-EL-D4B-xx-x-x tank gauge and compatible sensors are

properly installed, the sensors and the field wiring in the hazardous area will be incapable of releasing sufficient energy to cause ignition

of a Group C or D hazardous atmosphere.

The installation must comply with the requirements of the TG-EL-D4B Control Drawing 190789 (next page) and all requirements on the

control drawings of all associated apparatus in the hazardous location that is wired to the TG-EL-D4B terminals 21, 22, 51 through 70.

The Intrinsically Safe wiring must remain physically separated from all other non-Intrinsically Safe wiring by means of conduit, raceways,

partitions, or tie-downs. Tie-downs are acceptable if a 2" minimum separation is permanently maintained.

The ground wires connected to terminals 21 and 22 are an essential part of the Intrinsic Safety design of the TG-EL-D4B. Two

separate, independent, I.S. ground wires must be run from terminals 21 and 22 back to the grounding point of the AC power-supply

system with less than a 1-ohm resistance. This wiring can NOT be electrically combined with any other AC ground wiring. Splices are not

recommended. Follow all NEC and CSA codes for installation and marking of Intrinsically Safe wiring and grounding.

The capacitance and inductance of the field wiring cable affects the Intrinsically Safe design as noted on Control Drawing 190789.

Preferred p/n 92612 and 26000 cables are rated at less than 0.00005 uF/ft. and 0.0002 mH/ft.

1000-ft. cable runs, or less, of either 92612 or 26000 cable satisfies drawing 190789 I.S. capacitance and inductance requirements when

wired from from any TG-EL-D4B-xx-x I.S. input channel to any of the following: TG-EL-WF-7-C, TG-EL-WF-12-C, TG-EL-HLT-7-C, TG-

EL-HLT-15-C, TG-EL-ULT-18-C, HD-A2-C, or any simple switch.

"Simple switches" are inherently Intrinsically Safe and do not require UL, FM, CSA, or other approvals to be used in a hazardous location

when connected to an Intrinsically Safe associated apparatus (the TG-EL-D4B).

A "simple switch" is a mechanically actuated electrical contact that does not have any other electrical components (especially no added

capacitance and no added inductance). A simple switch does not store or discharge any electrical energy. All electrical energy is

provided by, and limited by, the I.S. design of the

TG-EL-D4B.

Non-Intrinsically Safe wiring notes:

Do not run low-voltage DC wiring bundled with, or in the same conduit as, AC wiring.

Ground DC shielded cables only where shown.

Insulate exposed shields to prevent connections to ground.

WARNING

Connecting Non-Intrinsically Safe devices to any Intrinsically Safe terminal voids the Intrinsically Safe

design and creates an explosion risk in the hazardous area

Instruction Manual SDI-TG-EL-D4B-xx-x-0 page 16 of 38 Revised 3/8/22

Preferred Utilities Manufacturing Corporation Firmware 1.06

HAZARDOUS LOCATION NON-HAZARDOUS LOCATION

Class I, Div 1, Groups C or D

Class I, Zone 0, Groups IIA or IIB

Ex ia IIB T4

Vmax (or Ui ) > 29.9V

Imax (or Ii ) > 99.5mA

Pmax (or Pi ) > 0.75W

Ci + Ccable < 0.25 uF

Li + Lcable < 1.5mH

Uo or Voc = 29.9V

Io or Isc = 99.5mA

Po = 0.75W

Co or Ca = 0.25 uF

Lo or La = 1.5mH

Um = 250Vac/dc

Ta = 0 - 50C

INTRINSICALLY SAFE

APPARATUS

ENTITY PARAMETERS

TG-EL-D4B-xx-x-x

ASSOCIATED APPARATUS

ENTITY PARAMETERS

TG-EL-D4B-xx-x-x

INTRINSICALLY

SAFE

ASSOCIATED

APPARATUS

(see manual for

channels 3 thru 8)

P2 54

C2 56

IS G 22

Power

Source

Less Than

250 Vac

NOTES:

1. ‘Electric Code’ means: ANSI/NFPA 70 National Electrical Code, or Canadian Electrical Code, or Local installation Codes, as applicable.

2. Control equipment connected to the TG-EL-D4B-xx-x-x must not use or generate more than 250 Vac or Vdc with respect to earth.

3. The Capacitance and Inductance of the field wiring cable from the TG-EL-D4B to the Intrinsically Safe Apparatus must be calculated and

included in the calculations in Note 4. Ccable = Cable Capacitance for the installed length, Ci = Intrinsically Safe Apparatus Internal

Capacitance (marked on the device), Ca = TG-EL-D4B Max Allowed Connected Capacitance (see above). The same descriptions apply

for inductance: Lcabl e , Li , and La . If the cable capacitance and inductance per foot is not known, use: Ccable = 0.00006 uF/foot and

Lcable = 0.0002 mH/foot.

4. Third Party Listed, Entity Rated, Intrinsically Safe Apparatus can be connected to TG-EL-D4B terminals 51 - 70 IF it is suitable for the

application AND it is installed in accordance with the manufacturers instructions AND all wiring is in accordance with the

TG-EL-D4B-xx-x-x instructions AND it satisfies ALL of the following relationships:

Intrinsically Safe Apparatus Associated Apparatus (TG-EL-D4B-xx-x-x)

Vmax ( or Ui ) > Voc ( or Vt or Uo )

Imax ( or Ii ) > Isc ( or It or Io )

Pmax ( or Pi ) > Po

Ci + Ccable < Ca ( or Co )

Li + Lcable < La ( or Lo )

5. A Switch (with no added capacitance or inductance) is a Simple Apparatus and does not require Third Party Approval in order to be

connected to the TG-EL-D4B. See the Electric Code and ANSI/NFPA article 504.

6. The TG-EL-D4B-xx-x-x MUST be connected to a suitable ground electrode per the Electric Code. Resistance from the TG-EL-D4B-xx-x-x

Intrinsically Safe Ground terminals 21 and 22 to the AC Power Source Ground Electrode must be less than 1 ohm.

Two independent I.S. Ground wires (14 ga. Min.) must be run from the TG-EL-D4B to Ground (one to terminal 21, one to terminal 22).

7. Intrinsically Safe wiring from the TG-EL-D4B to the Intrinsically Safe Apparatus must remain physically separated from non-Intrinsically Safe

wiring by means of conduit, raceways, partitions, or tie-downs which permanently maintain at least 2" separation.

See the Electric Code and ANSI/NFPA article 504.

8. Multiple Intrinsically Safe circuits may be run in the same conduit or raceway IF the total insulation thickness separating conductors of

different circuits is at least 0.020" (0.50mm). See ANSI/NFPA 70 article 504.

9. Special Note for Model TG-EL-D4B-00-0-0:

The TG-EL-D4B-00-0-0 must be installed in an enclosure suitable for the application in accordance with the NEC.

10. WARNING: No User serviceable Parts. Return to factory for all repairs.

IS G 21

P1 53

C1 55

S 51

only 2 of 8

circuits are

shown.

Simple Switch. (No

added Capacitance

or Inductance)

2 wire

4-20mA

xmtr

+

-

Preferred Utilities

31-35 South St., Danbury, CT

TG-EL-D4B-xx-x-x

Intrinsically Safe Entity Parameters

Control Drawing

190789

DRAWN: PL 4/16/21

SCAL E: none

REV. DATE BY

PROPRIETARY INFO RMATION NOTICE

THIS DOCUMENT CONTAINS PROPRIETARY

INFORMATION OF PREFERRED UTILITIES AND IS

SUBMITTED IN CONFIDENCE SOLE Y FOR THE

PURPOSE OF USE BY THE SELLER/PURCHASER

IN CONSIDERING THE M ERITS OF THE

DOCUMENT. NO OTHER USE, DIRE CT OR

INDIRECT, OF THE DOCUMENT OR INFO RMATION

DERIVED THERFROM IS AUTHORIZED.

. . .

. . .

. . .

. . .

. . .

. . .

. . .

Note: This drawing is part of the Intrinsic Safety Design and Approval. Do not implement any changes without the approval of the Preferred Eng Mgr and the Approval Agency.

DESCRIPTI ON

.

.

.

.

.

.

.

Instruction Manual SDI-TG-EL-D4B-xx-x-0 page 17 of 38 Revised 3/8/22

Preferred Utilities Manufacturing Corporation Firmware 1.06

TG-EL-D4B-xx-x-0 Field Wiring Terminals

(This is NOT the physical terminal arrangement)

53

55

54

56

57

59

52

58

60

61

63

69

62

64

22

44

46

71

73

75

78

L1

N

Ch.1 +22Vdc Out

Ch.1 mA Input

Shield / Ground

I.S. Ground

Shield / Ground

Ch.2 +22Vdc Out

Ch.2 mA Input

Ch.3 +22Vdc Out

Ch.3 mA Input

Ch.4 +22Vdc Out

Ch.4 mA Input

Ch.5 +22Vdc Out

Ch.5 mA Input

Ch.6 +22Vdc Out

Ch.6 mA Input

120 Vac Supply

50/60 Hz, 26 VA

WARNING: Intrinsically Safe Wiring to I.S. Devices ONLY See I.S. Control Drawing 190789)

Terminals 21, 22 , 51-70

are under the I.S. cover

65

67

70

66

68

Shield / Ground

Ch.7 +22Vdc Out

Ch.7 mA Input

Ch.8 +22Vdc Out

Ch.8 mA Input

9

11

12

13

10

Ch. 3 ROUT

Ch. 4 ROUT

Ch. 5 ROUT

Ch. 6 ROUT

120 Vac, 1.5A, PILOT

1

2

3

4

5

6

Ch. 1 ROUT

Ch. 2 ROUT

120 Vac, 8 FLA, 1/2 HP

Ch. 9 24V DC DIN

7Ch. 14 120V AC DIN

8Ch. 15 120V AC DIN

Ch. 10 24V DC DIN

Ch. 11 24V DC DIN

Ch. 12 24V DC DIN

Ch. 13 24V DC DIN

24V DC

-

43 24V DC

-

WARNING

Failure to comply with Control

drawing 190789, and the instruction

manuals of all Intrinsically Safe

sensors connected to the TG-EL-D4B,

voids the Intrinsically Safe design and

creates an explosion risk in the

hazardous area.

40

39

42

41

Ch.1

4-20mA

Output

+

-

+

-

Ch.2

4-20mA

Output

48

50

77

79

81

83

Ethernet

86

DOUT DC -

80

82

Tx

Rx

84

DC-

Printer

RS232

45

47

A+

B-

49

Common

RS485

Modbus

Ch. 7 DOUT

Ch. 8 DOUT

Ch. 9 DOUT

Ch. 10 DOUT

Ch. 11 DOUT

Ch. 12 DOUT

I.S. Ground

21

51 Shield / Ground

86

DOUT DC +

Instruction Manual SDI-TG-EL-D4B-xx-x-0 page 18 of 38 Revised 3/8/22

Preferred Utilities Manufacturing Corporation Firmware 1.06

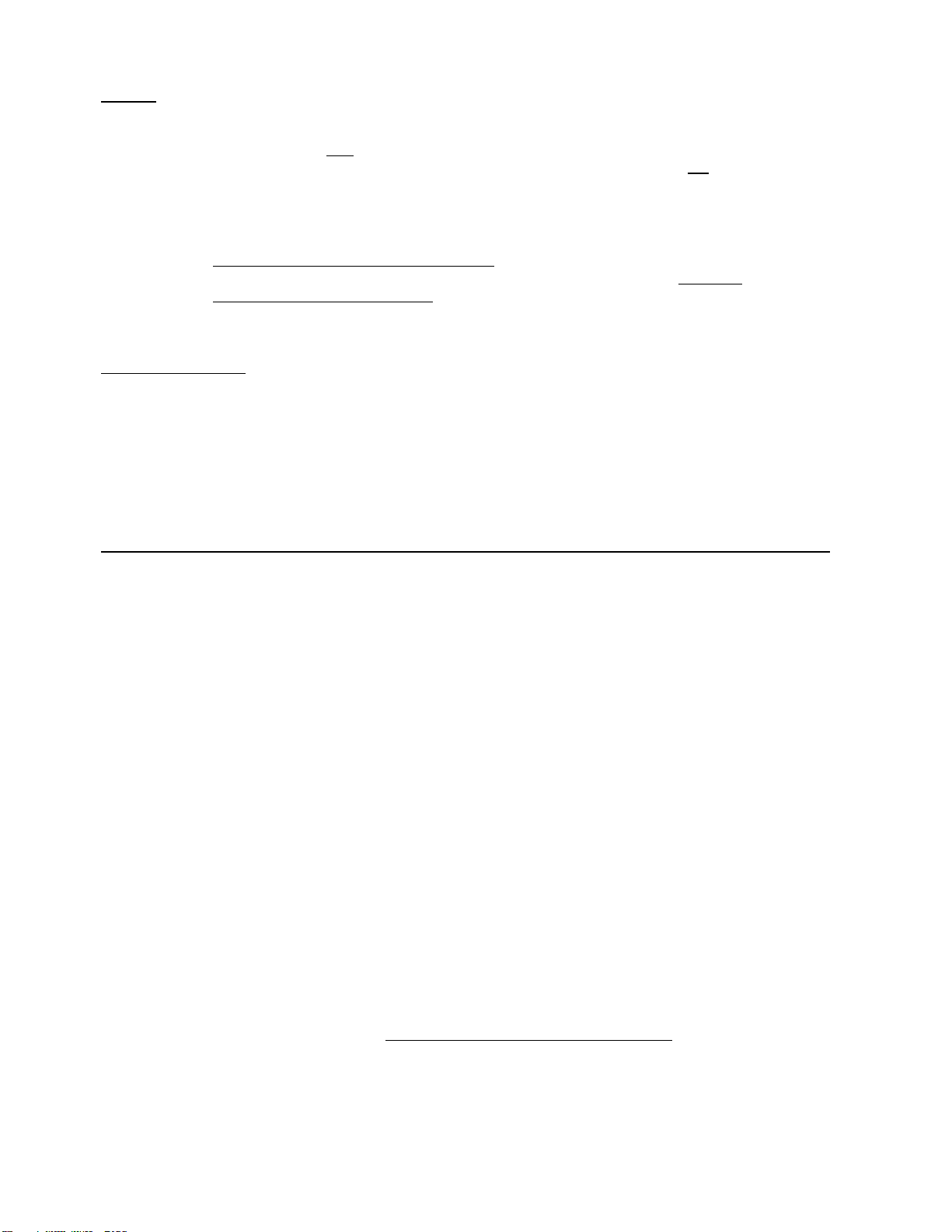

TG-EL-D4B-00-0-0

Field Wiring Terminal Block Arrangement (Rear View)

See the worksheets on pages 12 - 13 for I/O channel terminal numbers

74

76

78

80

82

84

86

72

73

75

77

79

81

83

85

71

USB (Main)

Ethernet

LED

1

2

3

4

(Aux) USB

Remote

I/O

LED 1

2

Fuse

3.15A

SLO-BLO

70

68

54

56

58

60

62

64

66

52

69

67

53

55

57

59

61

63

65

51

22

21 Intrinsic

Safety

Terminals

Cover

DC -

C8 -

C2 +

C2 -

C4 +

C4 -

C6 +

C6 -

C8 +

DC -

DC -

C7 -

C1 +

C1 -

C3 +

C3 -

C5 +

C5 -

C7 +

DC -

IS Gnd (DC -)

IS Gnd (DC -)

50

48

34

36

38

40

42

44

46

32

DO8

DO7

AO1+

AO2+

DI9

DI10

485C

485-

DC -

DC -

DC -

DC -

485+

49

47

33

35

37

39

41

43

45

31

DI15

DI14

R2 NC

R2 C

R2 NO

R1 NC

R1 C

R1 NO

L1

L1

N

N

8

7

6

5

4

3

2

1

13

12

11

10

9

R3-6 C

R6 NO

R5 NO

R4 NO

R3 NO

DC -

PR T

PR R

DC-

DO -

DI12

DI13

DO9

DO10

DO11

DO12

DO +

DI11

Terminal Number Notes:

L1, N, 7, 8 are 120Vac circuits

1-5, 9-13 are relay dry contacts.

Can be a mixture of 120Vac

and Low Voltage DC circuits

31-50, 71-86 are low voltage DC

circuits

21-22, 51-70 are Intrinsically Safe (IS)

circuits. IS wiring must be kept at

least 2" away from all other wiring

Instruction Manual SDI-TG-EL-D4B-xx-x-0 page 19 of 38 Revised 3/8/22

Preferred Utilities Manufacturing Corporation Firmware 1.06

The following partial schematics are included as an aid to troubleshooting.

AIN ch. 1-8: 4-20mA Xmtr Intrinsically Safe

Total Loop Ohms = Field Wiring Ohms + 442 Internal Ohms

53

55

51

392

50.0

ohms

+ 24 V

to A/D conv.

(20mA = 1.333V)

+

-

2 Wire

4-20mA

Xmtr

Inputs 1-8 Schematic Overview

( I.S. Barrier parts not shown)

22.5-27.5 mA

Limiter

AIN ch 1

terminals shown

AIN ch. 1-8: Contact Closure Sensor Intrinsically Safe

22.5-27.5 mA when

Contact is Closed

57

59

51

392

50.0

ohms

to A/D conv.

(20mA = 1.000V)

Inputs 1-8 Schematic Overview

( I.S. Barrier parts not shown)

22.5-27.5 mA

Limiter + 24 V

AIN ch 3

terminals shown

AC DIN ch. 14-15: Contact Closure Sensor Non-Intrinsically Safe

7

to CPU

+V

TG-EL-D4B “N”

AC DIN ch 14

terminals shown

TG-EL-D4B

120V “L1” 11 mA when

Contact is Closed

DC DIN ch. 9-13: Sinking Contact Closure Input Non-Intrinsically Safe

46

+24V

43

to CPU

DC DIN ch 10

terminals shown

1 mA when

Contact is Closed

DC DOUT ch. 7-12: Sinking Outputs Non-Intrinsically Safe

77

86

CPU

External

12-36 Vdc

power

supply

+

-

Install clamp diode

directly onto relay

or solenoid coil

DOUT -

85

DOUT +

DOUT ch. 9

Terminals 85 & 85 are common to all DOUT channels

Instruction Manual SDI-TG-EL-D4B-xx-x-0 page 20 of 38 Revised 3/8/22

Preferred Utilities Manufacturing Corporation Firmware 1.06

Level Sensor Type Setup &

"Stick Depth"

The TG-EL-D4B accommodates three different methods to determine the fluid depth: ullage, depth, and head.

This section discusses each method, the calibration data, and “depth adjust.”

The SENSOR TYPE determines the

measurement type and default calibration.

SENSOR TYPE

Description

Measurement

Type

Default

20 mA Cal.

Default

4 mA Cal.

CM-LITER

20 mA Cal.

LVL WF7

Level sensor, 7 ft., TG

-

EL

-

WF

-

7

-

C

Ullage

84.0 ullage

0.0

213.4

LVL WF12

Level sensor, 12 ft.,

TG

-

EL

-

WF

-

12

-

C

Ullage

144.0 ullage

0.0

365.8

LVL UL18

Level sensor, 18 ft., TG

-

EL

-

UL

-

18

-

C

Ullage

216.0 ullage

0.0

548.7

LVL OTHER

Level sensor, other 4

-

20 mA

Depth

100.0 depth

0.0

254.0

HEAD HL7

Head level sensor, 7 ft., TG

-

EL

-

HLT

-

7

-

C

Head

80.0" of

water

n/a

203.2 cm WC

HEAD HL15

Head level sensor, 15 ft.,TG

-

EL

-

HLT

-

15

-

C

Head

160.0" of water

n/a

406.4 cm WC

HEADOTHER

Head level sensor, other 4

-

20 mA

Head

100.0" of water

n/a

254.0 cm WC

When the SENSOR TYPE is changed, the calibration is changed automatically to the above defaults.

The default calibration data for sensors LVL OTHER, HEADOTHER, and LVL UL18 must be changed by the user to reflect the

calibration of the sensor being used.

The calibration data for SENSOR TYPES: LVL WF7, LVL WF12, HEAD HL7, and HEAD HL15 should not be changed and must be set

to the above default values.

The default units are: IN-GALLON (inches-gallons). Units can be changed to CM-LITER (centimeters-liters) via the UNITS selection in

CONFIGURE MENU. If CM-LITER units are used, the 20 mA calibration must be changed manually to the equivalent cm values in the

table above via the INPUT X SENSOR CONFIG menu.

Fluid depth methods

Ullage is the distance from the top of the tank down to the top of the fluid.

Actual depth = (tank full height – ullage) + depth adj.

Depth is the distance from the top of the fluid down to the bottom of the

tank.

Actual depth = xmtr depth + depth adj.

Head is the pressure at the bottom of the tank caused by the weight of the

fluid above it. Head sensors measure this pressure in "Inches of Water

Column" or in "Centimeters of Water Column" units.

Actual depth = ("WC x Specific Gravity) + Depth Adj.

The specific gravity is entered via the TANK x SIZING menu.

(continued on next page)

TG-EL-WF-7-C

4-20mA

Ullage

Signal:

Fluid Level

71.5"

Depth

Ullage

84" (7 ft)

0" Ullage

4.00 mA

71.5" Ullage

17.62 mA

84" Ullage

20.00 mA

Vent

'Head' sensor inside tank

measures:

Inches of Water Column

This manual suits for next models

1

Table of contents

Other Preferred Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

IDEAL

IDEAL 61-732 instruction manual

NARDA

NARDA SRM-3006 Command reference guide

Zenner

Zenner IUW Series Installation and operating instructions

INFLUX MEASUREMENTS

INFLUX MEASUREMENTS FIRESURE FIREGROOVE GUIDE TO THE INSTALLATION, OPERATION AND MAINTENANCE

AFLOWT

AFLOWT BUF Operation manual

H2flow

H2flow FlowVis DN50 operating manual