Pro-face GP-377 Series User manual

• Do not strike the GP's touch panel with a hard or heavy object, or press

on the touch panel too strongly since it may damage the display.

• Do not install the GP where the temperature will exceed its specified range.

• Be sure that water, liquids or metal particles do not enter the GP, since

it may cause a malfunction or a short circuit.

• Avoid installing the GP where sudden, large changes in temperature

may occur. These changes may cause condensation to form inside the

unit, possibly causing a malfunction.

• To prevent excessive heat from building up inside the GP, do not in-

stall it where its ventilation holes may be blocked.

• Do not install or store the GP :

- Where direcdt sunlight or or high levels of dust exist.

- Where either strong shocks or excessive vibration may occur.

- In an area containing chemicals or chemical fumes.

- Near high temperature equipment.

• Do not use paint thinner or organic solvents to clean the GP's case or

screen.

• Due to the danger of unforeseeable accidents, be sure to back up all data

regularly.

• After turning the GP OFF, be sure to wait a few seconds before turning

it ON again. If the GP is re-started too quickly, it may not start up cor-

rectly.

• When connecting the power cord terminals to the GP, be sure the cord

has first been unplugged from the power outlet to prevent the possibil-

ity of an electric shock.

• With the exception of changing the GP's backlight, do NOT open the

GP's case, since high voltage runs through the GP and touching an in-

ternal part can lead to an electric shock.

• Do not use power beyond the GP's specified voltage range. Doing so

may cause a fire or an electric shock.

• Do not modify the GP's design, since it may lead to a fire or an electric

shock.

• Do not use the GP in an environment where flammable gases are present,

since operating the GP may cause an explosion.

• The GP uses a lithium battery for backing up its internal clock data. If

the battery is incorrectly replaced (i.e. its + and — sides are reversed),

the battery may explode. When changing the battery, please contact

your local GP distributor.

• Do not use GP touch panel switches in life-related or important disaster

prevention situations. For safety related switches, such as an emer-

gency switch, be sure to use a separate mechanical switch.

• To prevent operator injury or machine damage, be sure to design your

machine operation system so that the machine will not malfunction due

to a communication fault between the GP and its host controller.

■GP-377 Series

User’s Manual *1

(Sold Separately)

■Cables

■Adapters

■Screen editor software, etc.

For more information on these items,

please refer to Digital's GP catalogues.

GP377-SC11-24V

GP377-LG11-24V

(English/Japanese)

GP Options (Made by Digital)

Digital

GP-377

Series

User's Manual

Package Contents

The following items are included in the GP's package. Before using the GP, please

confirm that all items shown here are present.

This unit has been carefully packed, with special attention to quality. However, should

you find anything damaged or missing, please contact your local GP distributor imme-

diately.

■GP Unit (1)

(GP377-SC11-24V,

GP377-LG11-24V)

■Installation fasteners (4)■Installation guide(1)

<This Guide>

(GP377-SC11-24V,

GP377-LG11-24V)

Installation

Guide

*1 Please refer to this manual for detailed GP information.

2GP-377 External Dimensions

1GP-377 Parts Names and Functions

A,BC

A: Display

Displays User-created screens and host (PLC)

data.

GP377-SC11-24V : Color LCD

GP377-LG11-24V : Monochrome LCD

B: Touch Panel

Performs screen change operations and sends data

to the host (PLC).

C: Status LED

LED GP Status

Not Lit Power cord is notconnected.

Green Normal operation

Orange Backlight is notfunctioning

(Refer to Section 9. Changing the Backlight)

D: Power Input Terminal Block

Connects the GP power cable's input and ground

wires to the GP.

E: Expansion Unit Interface

Connects an optional GP Expansion Unit to the GP.

(Inside cover)

F: Serial Interface

Connects an RS-232C or RS-422 (Serial) cable

(from the host/PLC) to the GP.

G: Tool Connector

Connects the Data Transfer Cable, Bar Code Reader,

Memory Loader or other equipment to the GP.

DF

EG

Unit:mm

TopView

SideView

57

5

123.0

155.5

171

Front View

138

RearView

Recommended Connector: Dsub25pin(male) XM2A-2501<made by OMRON Corp.>

Recommended Cover: Dsub 25pin XM2S-2511<made by OMRON Corp.>

Jack Screws XM2Z-0071<made by OMRON Corp.>

Use rough metric type M2.6 x 0.45p threads to hold the cable's set

(fastening) screws in place.

Recommended Cable: CO-MA-VV-SB5P x 28AWG <made by HITACHI Cable>

Pin # Signal Name Meaning

1 FG Frame Ground

SIO 2 SD Send Data (RS-232C)

3 RD Receive Data (RS-232C)

4 RS Request to Send (RS-232C)

5 CS Clear to Send (RS-232C)

6 NC No Connection

7 SG Signal Ground

8 CD Carrier Detect (RS-232C)

9 TRMX Termination(RS-422)

10 RDA Receive Data A (RS-422)

11 SDA Send Data A (RS-422)

12 *1 RESERVED RESERVED

13 *1 RESERVED RESERVED

14 VCC 5V Output 0.25A

15 SDB Send Data B (RS-422)

16 RDB Receive Data B (RS-422)

17 NC No Connection

18 CSB Clear to Send B (RS-422)

19 ERB Enable Receive B (RS-422)

20 ER Enable Receive (RS-232C)

21 CSA Clear to Send A (RS-422)

22 ERA Enable Receive A (RS-422)

23 BUZZ GND ExternalBuzzer Ground

24 NC No Connection

25 BUZZ OUT External Buzzer Output

25

13

141

This interface is for connecting the GP to the host (PLC), via either an RS-232C or

RS-422 cable.

3Serial Interface

*1 Pins Number12 and 13 are reserved and should not be con-

nected to anything.

• Since pin #14 (VCC) is not protected, be sure to use it only

within its rated range.

• Be sure to connect pin #7 (SG) to the other unit's Signal

Ground terminal.

When making a cable, please be aware of the following:

<For RS-232C Connectors>

• Do not connect #9 (TRMX), #10 (RDA), #11 (SDA), #15 (SDB), #16

(RDB), #18(CSB), #19 (ERB), #21 (CSA), and #22 (ERA).

<For RS-422 Connectors>

• The following pairs of pin numbers' must be connected (shorted):

#18 (CSB) <-> #19 (ERB)

#21 (CSA) <-> #22 (ERA)

• Connecting the #9 (TRMX) and #10 (RDA) wires adds a termination

resistance of 100W between RDA and RDB.

• Use a 4-wire cable when the PLC type is Memory Link and the cable is

RS-422.

<External Buzzer Output>

Use pins 23(BUZZ GND) and 25(BUZZ OUT) when producing external

output for an alarm.

External Buzzer Output Buzzer Can drive a DC5 to

24V (up to 0.3A)

buzzer.

Internal

Circuit

SIO 25 Pin

SIO 23 Pin

GP-377 Unit

Optical Isolation

■Confirm the Installation Gasket’s Seating

It is strongly recommended that you use the gasket.

Place the GP on a level surface with the display panel facing downward. Check that

the GP’s installation gasket is seated securely into the gasket’s groove, which runs

around the perimeter of the panel’s frame.

■Attach the GP's Installation Fasteners from inside the panel.

Tighten the installation fasteners with a standard screwdriver.

Tightening the fastener screws with too much force can

damage the GP's case. The torque necessary to ensure a

waterproof seal is 0.5 to 0.6N•m.

■Cut a hole in the metal panel according to the dimensions given below.

Insert the GP into the panel from the front of the panel.

Metal Panel

156

under 4-R3

123.5

Panel thickness should be

from 1.6mm to 5.0mm

Unit:mm +1

- 0

+1

- 0

GP Unit

4Installation

Installation Gasket

Rear of GP

Before installing the GP into a cabinet or panel, check

that the Installation gasket is securely attached to the

unit.

5Wiring

Under

6.0mm

Over φ 3.2mm

•To prevent an electric shock, be sure the GP's Power Cord is un-

plugged from the power outlet prior to connecting the cord's termi-

nals to the GP.

•The GP377Series are designed to use only DC24V input. Any other

power level can damage both the GP and the power supply.

•Be sure to reattach the GP Power Terminal's clear plastic cover after

connecting the Power Cord's power terminals.

■Connecting the GP's Power Cord

When connecting the power cord, be sure to follow the procedures given below.

1. Confirm that the GP's Power Cord is unplugged from the power supply.

2. Use a screwdriver to remove the Power Input Terminal Block's clear plastic

cover.

3. Connect the power terminals and check that the wires are connected correctly.

4. Replace the Power Input Terminal Block's clear plastic cover.

Rear of GP

*1 Suggested Ring Terminal: V2-MS3 (made by JST Co.)

• Since the GP has no power switch, install a breaker-type switch.

Power Input Terminal Block

Ring Terminals

+

--

FG

The torque required for fastening the screws is 0.5 to 0.6N•m.

• When connecting a wire to the GP's FG terminal, be sure the wire

is grounded. Not grounding the wire will result in excessive

noise.

• To avoid a short caused by loose ring terminals, be sure to use

ring terminals with an insulating sleeve.

• Wherever possible, use thick wires (max. 2 mm2) for power terminals, and twist

the wire ends before attaching the ring terminals.

• Be sure to use the following size ring terminals.*1

6Power Supply Precautions

Be aware of the following items when attaching the power cord terminals to the GP's

power terminal block.

• When operating the GP where large power fluctuations will occur, install a constant

voltage transformer.

• To reduce wire-to-wire or wire-to-earth noise as much possible, use a low-noise

power supply. If noise is excessive, use a Noise Reducing Transformer.

• Be sure to separate all GP power, I/O unit and Operation unit lines.

• To increase the noise resistance of the power cord's wires, twist each end before

attaching the Ring Terminal.

• Do not bundle or position the GP's power cord near main circuit lines (high voltage,

strong current), or I/O signal lines.

• To prevent damage from lightning, be sure to install a lightning surge absorber

• To minimize line noise, make the GP's power cord as short as possible.

*1 Use a grounding resistance of 100

Ω

, a wire of 2mm2or thicker, or your country's

applicable standard.

7Grounding Precautions

• When attaching a wire to the GP's rear face FG terminal, (on the Power Input Terminal

Block), be sure to create an exclusive ground.*1

8I/O (Input/Output) Signal Line Precautions

•All GP Input and Output signal lines must be separated from all operating circuit

(power) cables.

•If this is not possible, use a shielded cable and ground the shield.

9Changing the Backlight

• Be sure the GP's power Cord is unplugged from the power outlet

prior to changing the Backlight.

• Do not touch any of the GP's internal parts while the unit is still

ON, since high voltage runs through the Backlight area.

• When the power has just been turned OFF, the unit and Backlight

are still very hot. Be sure to use gloves to prevent burns.

WARNING

Check you have the proper backlight for the GP-377 Series.

GP Backlight Model

GP377-SC11-24V

GP377-LG11-24V GP377L/S-BL00-MS

When the unit's backlight burns out, the unit's status LED will turn orange. If the

"USE TOUCHPANEL AFTER BACKLIGHT BURNSOUT" feature is set to "NO",

the GP's touch panel will be disabled. *1

*1 If "NO" has been selected for the OFFLINE menu's "FORCE RESET" feature, Touch-

Panel operation is disabled.

Power Cable

A

Fastening Clip

B

Change the Backlight following the steps below. Be sure to use gloves.

1) Disconnect the GP's Power Cord from the

power supply.

2) Remove the power cord terminals from

the GP. (See figure A)

3)

Use a screwdriver to unscrew the two

screws attached on the unit’s top face. Keep

pushing the Fastening Clip and open the

top face. Be sure the clip-tab does not get

caught. (See figure B)

4) Disconnect backlight power connec-

tor on the upper side of the GP's front

panel. Do not pull the cord. (See fig-

ure C)

5) Push the Lock Tab to the right and pull

itupward,andthenremovethebacklight.

(See figure C)

6) Insert the new Backlight into the slot

from the opposite side of the Lock

Tab, then Lock Tab side.

7) Reattach the Power Connector to the

GP.

8) To replace the rear cover, insert the

cover's guide tabs into the case's guide

slots and close the cover. Be sure that

the Rear Cover Connector and the

Front Cover Connector are con-

nected properly. (See figure D)

D

Hook

Frontside Connector

Rear Cover Connector

Guide Slot

Power Connector

Cord

C

Lock Tab

This manual suits for next models

2

Table of contents

Other Pro-face Control Unit manuals

Pro-face

Pro-face PRO-iO2 User manual

Pro-face

Pro-face GP-37W3 Series User manual

Pro-face

Pro-face AGP3000 User manual

Pro-face

Pro-face PL-5900 Series User manual

Pro-face

Pro-face GP4000 SERIES User manual

Pro-face

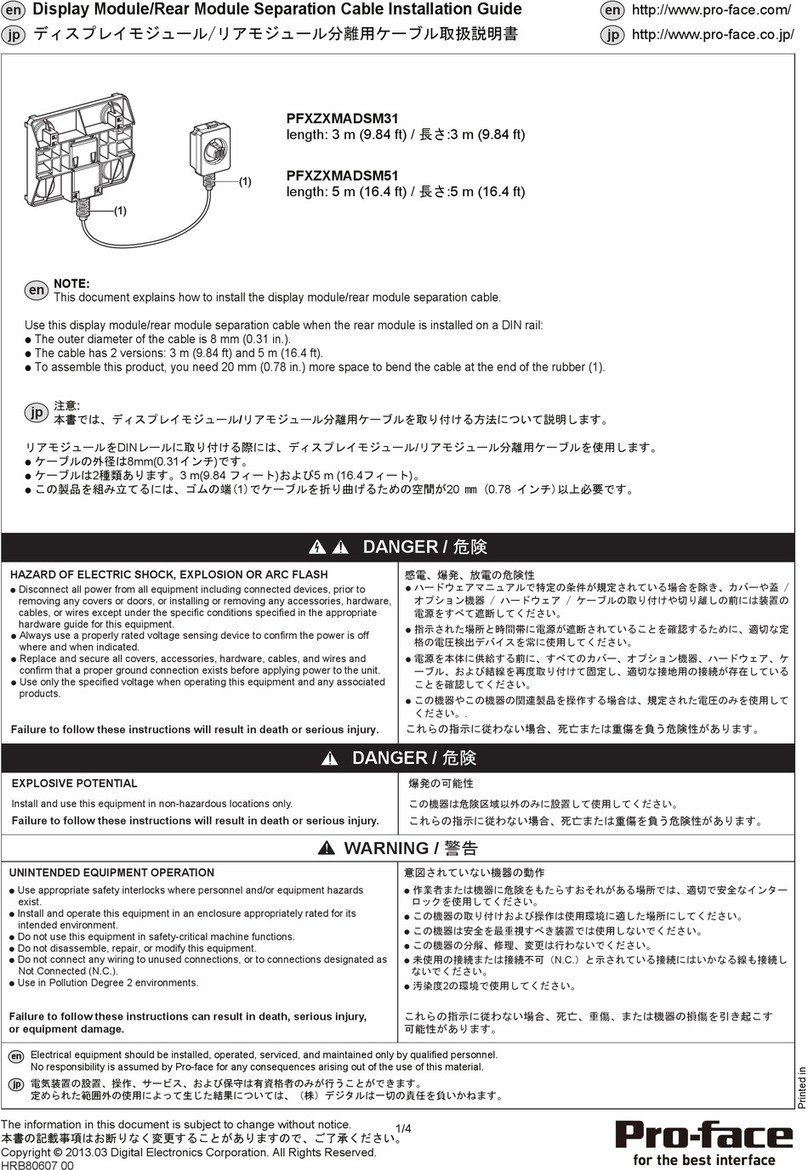

Pro-face PFXZXMADSM31 User manual

Pro-face

Pro-face CA2-ISOALL422-01 User manual

Pro-face

Pro-face SP-5B10 User manual

Pro-face

Pro-face GP377R-TC11-24V User manual