1

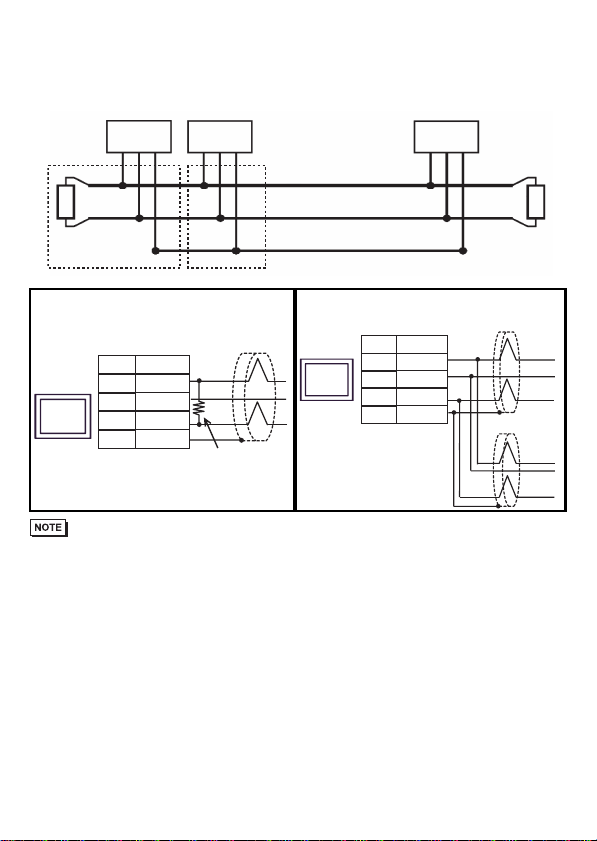

GP3000 Series

CANopen Interface

Installation Guide

Package Contents

(1) Installation Guide (1) <This Guide>

This unit has been carefully packed, with

special attention to quality. However, should

you find anything damaged or missing, please

contact your local GP distributor immediately.

About the Manual

For the detailed information on GP3000

series, refer to the following manual.

• GP3000 Series Hardware Manual

• Maintenance/Troubleshooting Guide

The manuals can be selected from the help

menu of GP-Pro EX or downloaded from

Pro-face Home Page.

URL

http://www.pro-face.com/

Caution

Be sure to read the “Warning/Caution

Information” on the attached sheet before

using the product.

CAUTION

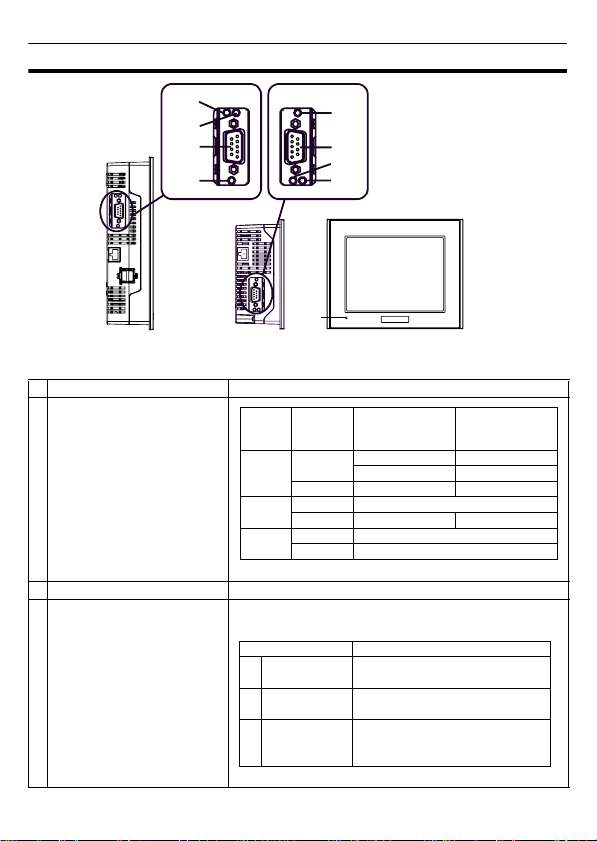

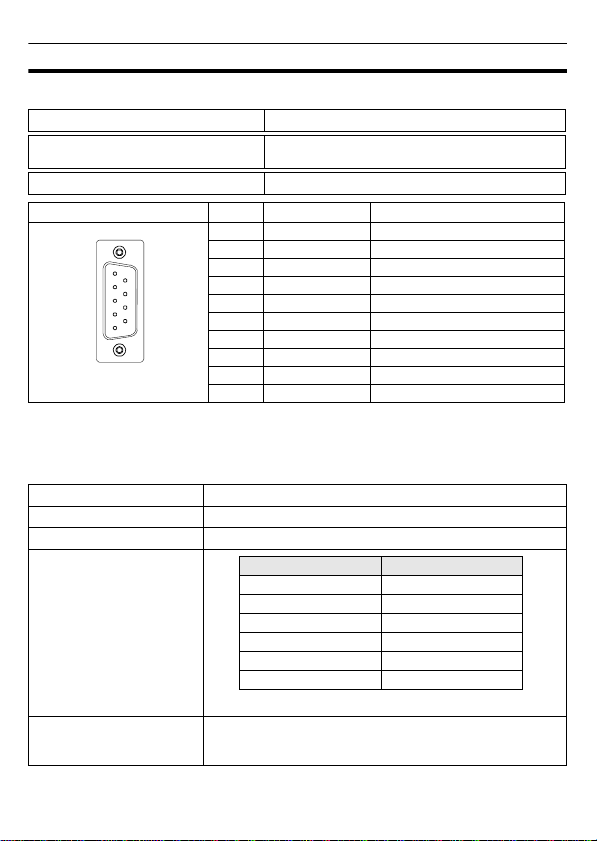

This manual describes the part names and

general specifications related to the

CANopen I/F included with the CANopen

board type unit of the GP3000 series, as

well as the wiring to the CANopen

connector. Before using the CANopen

connector, be sure to read this Installation

Guide in conjunction with the attached

GP3000 Series’ Installation Guide.