Pro-face LT-4201TM User manual

LT-4201TM/4301TM

Installation Guide

2

English

The information provided in this documentation contains general descriptions and/or

technical characteristics of the performance of the products contained herein. This

documentation is not intended as a substitute for and is not to be used for determining

suitability or reliability of these products for specific user applications. It is the duty of any

such user or integrator to perform the appropriate and complete risk analysis, evaluation

and testing of the products with respect to the relevant specific application or use thereof.

Neither Pro-face nor any of its affiliates or subsidiaries shall be responsible or liable for

misuse of the information that is contained herein. If you have any suggestions for

improvements or amendments or have found errors in this publication, please notify us.

No part of this document may be reproduced in any form or by any means, electronic or

mechanical, including photocopying, without express written permission of Pro-face.

All pertinent state, regional, and local safety regulations must be observed when installing

and using this product. For reasons of safety and to help ensure compliance with

documented system data, only the manufacturer should perform repairs to components.

When devices are used for applications with technical safety requirements, the relevant

instructions must be followed.

Failure to use Pro-face software or approved software with our hardware products may

result in injury, harm, or improper operating results.

Failure to observe this information can result in injury or equipment damage.

Copyright © 2016.06 Digital Electronics Corporation. All Rights Reserved.

3

LT-4201TM/4301TM Installation Guide

English

Safety Information

Important Information

NOTICE

Read these instructions carefully, and look at the equipment to become familiar with the

device before trying to install, operate, or maintain it. The following special messages may

appear throughout this documentation or on the equipment to warn of potential hazards or

to call attention to information that clarifies or simplifies a procedure.

4

English

PLEASE NOTE

Electrical equipment should be installed, operated, serviced, and maintained only by

qualified personnel. No responsibility is assumed by Pro-face for any consequences arising

out of the use of this material.

A qualified person is one who has skills and knowledge related to the construction and

operation of electrical equipment and its installation, and has received safety training to

recognize and avoid the hazards involved.

5

LT-4201TM/4301TM Installation Guide

English

About the Book

At a Glance

Thank you for purchasing Pro-face's LT4000 Series Graphic Logic Controller Interface

(Hereafter referred to as the "LT").

Document Scope

This guide describes how to install the LT-4201TM/4301TM. For more detailed information,

refer to the manuals indicated below.

Global Code

A global code is assigned to every Pro-face product as a universal model number.

For more information on product models and their matching global codes, please refer to

the following URL:

http://www.pro-face.com/trans/en/manual/1003.html

Validity Note

This documentation is valid for GP-Pro EX V4.0 or later.

The characteristics presented in this manual should be the same as those that appear

online. In line with our policy of constant improvement we may revise content over time to

improve clarity and accuracy. In the event that you see a difference between the manual

and online information, use the online information as your reference.

Related Documents

You can download these technical publications and other technical information from our

support site at http://www.pro-face.com/trans/en/manual/1001.html.

Title of Documentation Reference Number

GP-Pro EX Reference Manual

Maintenance/Troubleshooting Guide

• Troubleshooting

Help for solving problems.

• Maintenance

Details on the LT unit’s Offline Mode

GP-Pro EX Device/PLC Connection Manual System configuration of connected

devices (PLCs and other devices),

communication settings examples,

connection wiring diagram, and other

details.

LT-4201TM/4301TM Hardware Manual Specifications, dimensions,

accessories, system design,

standards, and other details.

6

English

Product Related Information

This equipment has been designed to operate outside of any hazardous location. Only

install this equipment in zones known to be free of a hazardous atmosphere.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

Disconnect all power from all equipment including connected devices prior to

removing any covers or doors, or installing or removing any accessories, hardware,

cables, or wires except under the specific conditions specified in the appropriate

hardware guide for this equipment.

Always use a properly rated voltage sensing device to confirm the power is off where

and when indicated.

Replace and secure all covers, accessories, hardware, cables, and wires and confirm

that a proper ground connection exists before applying power to the unit.

Use only the specified voltage when operating this equipment and any associated

products.

Failure to follow these instructions will result in death or serious injury.

DANGER

POTENTIAL FOR EXPLOSION

Install and use this equipment in non-hazardous locations only.

Failure to follow these instructions will result in death or serious injury.

LT-4201TM/4301TM Installation Guide

7

English

1 For additional information, refer to NEMA ICS 1.1 (latest edition), "Safety Guidelines for

the Application, Installation, and Maintenance of Solid State Control" and to NEMA ICS 7.1

(latest edition), "Safety Standards for Construction and Guide for Selection, Installation and

Operation of Adjustable-Speed Drive Systems" or their equivalent governing your particular

location.

WARNING

LOSS OF CONTROL

Consider the potential failure modes of control paths in the machine control system

design, such as:

The possibility of backlight failure,

Unanticipated link transmission delays or failures,

The operator being unable to control the machine,

The operator making errors in the control of the machine.

Design outside the LT operations such as emergency stop, safety circuits, interlocks

that operate with opposing actions such as clockwise/counterclockwise rotation, and

circuits that prevent machine damage with positioning limits on top, bottom, and

movement.

For important operations handled by switches, design your system to use a separate

hardware device. This is to reduce the occurrence of incorrect outputs or

malfunctions.

Observe all accident prevention regulations and local safety guidelines.1

Test individually and thoroughly each implementation of the equipment for correct

operation before service.

Failure to follow these instructions can result in death, serious injury, or equipment

damage.

8

English

9

LT-4201TM/4301TM Installation Guide

English

LT-4201TM/4301TM In stallation Guide

LT-4201TM/4301TM

LT-4201TM/4301TM of Panel s

LT-4201TM/4301TM of Panels

LT Range

Thank you for purchasing Pro-face's LT4000 Series unit (hereafter referred to as the “LT”):

NOTE: Fast Input and Fast Output are generic terms for the following functions:

Fast Input: High-speed Counter Input and Pulse Catch Input.

Fast Output: Pulse Output, PWM Output and High-speed Counter Synchronize Output.

Series Model Names Models Digital

Input

Digital

Output

Analog Input Analog

Output

Screen

Size

LT4000

Series

LT-4201TM

(Modular Type

DIO)

PFXLM4201TADDC

PFXLM4201TADDK

20 Points

Standard

Input

(2 Points

for Fast

Input)

10 Points

Standard

Output

and

2Points

Fast

Output

None None 3.5 in.

LT-4301TM

(Modular Type

DIO)

PFXLM4301TADDC

PFXLM4301TADDK

5.7 in.

LT-4000M

(Modular Type

DIO)

PFXLM4B01DDC

PFXLM4B01DDK

None

LT-4201TM

(Modular Type

Analog)

PFXLM4201TADAC

PFXLM4201TADAK

12 Points

Standard

Input

(2 Points

for Fast

Input)

6Points

Standard

Output

and

2Points

Fast

Output

2 ch analog

inputs (13-bit)

and 2 ch

analog inputs

(16-bit) for

Thermocouple

2ch

analog

outputs

(12-bit)

3.5 in.

LT-4301TM

(Modular Type

Analog)

PFXLM4301TADAC

PFXLM4301TADAK

5.7 in.

LT-4000M

(Modular Type

Analog)

PFXLM4B01DAC

PFXLM4B01DAK

None

3.5 inch

display

module

PFXXM4200TP None 3.5 in.

5.7 inch

display

module

PFXXM4300TP None 5.7 in.

LT-4201TM/4301TM

10

English

Display Module/Rear Module Separation Cable Range

Agency Certifications for LT Unit

For information on Standards and Regulations, such as certified models and certificates,

see the marking on the product or the following link:

http://www.pro-face.com/trans/en/manual/1002.html

LT unit is manufactured in accordance with UL 508 and CSA C22.2 n°142 for industrial

control equipment.

For use on a flat surface of a Type 1, Type 4X (indoor use only) enclosure.

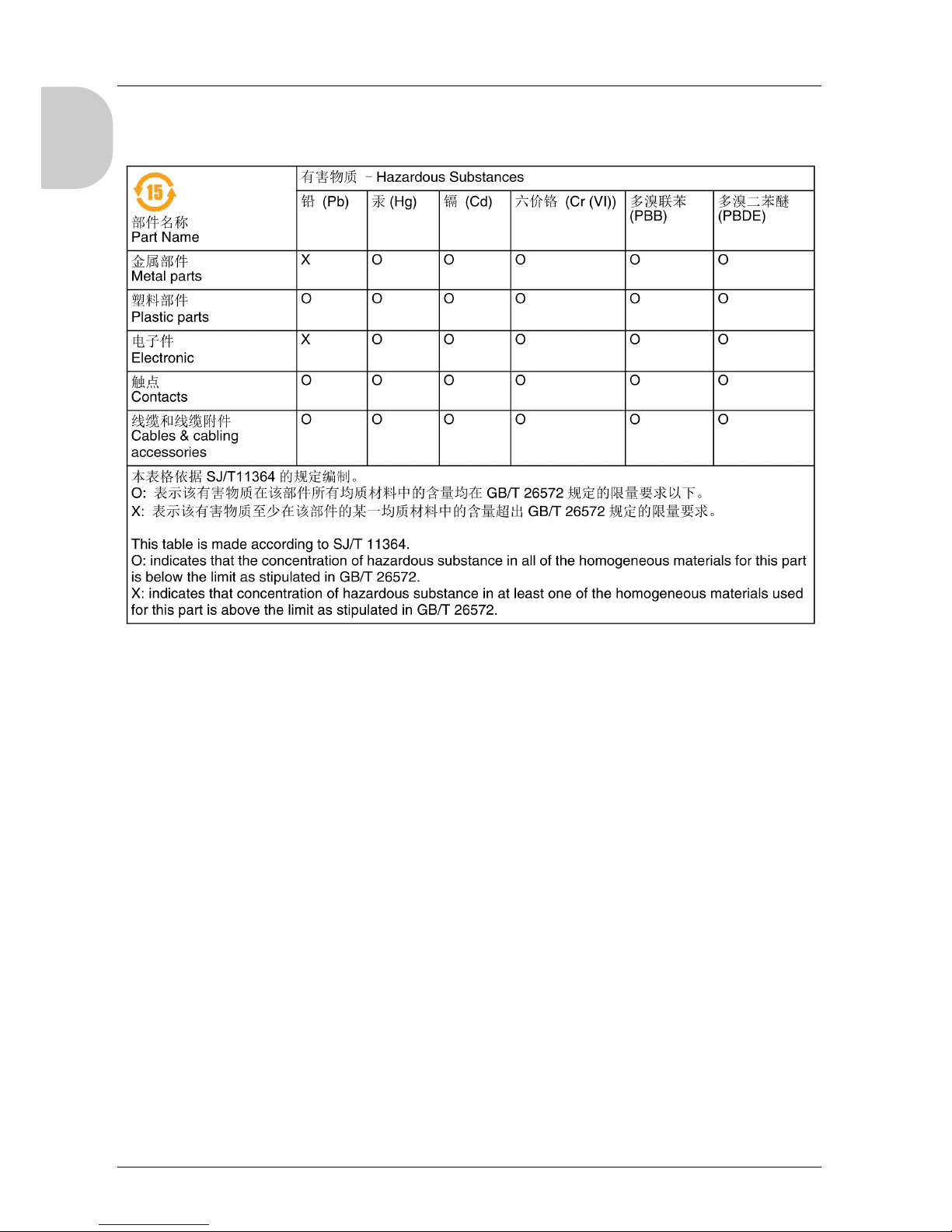

Hazardous Substances

This product is a device for use in factory systems. When using this product in a system,

the system should comply with the following standards in regards to the installation

environment and handling:

WEEE, Directive 2012/19/EU

RoHS, Directives 2011/65/EU

RoHS China, Standard SJ/T 11364-2014

REACH regulation EC 1907/2006

CE Markings

This product conforms to the necessary requirements of the following Directives for

applying the CE label:

2006/95/EC Low Voltage Directive

2004/108/EC EMC Directive

This conformity is based on compliance with IEC61131-2.

Reference Cable Length

PFXZXMADSM31 3 m (9.84 ft.)

PFXZXMADSM51 5 m (14.40 ft.)

NOTE: The outer diameter of the cable is 8 mm (0.13 in.). To assemble this product, you need

20 mm (0.78 in.) more space to bend the cable in the end of the rubber.

LT-4201TM/4301TM Installation Guide

11

English

Interfaces are: COM1, Ethernet, USB1 and USB2.

CAUTION

ENVIRONMENTAL HAZARDS TO THE EQUIPMENT

Allow the device to reach the surrounding air temperature, not exceeding 50 °C

(122 °F), before turning the device on.

Do not turn on the device if condensation has occurred inside the device. After it is

completely dry again, the device may be turned on.

Do not expose the device to direct sunlight.

Do not obstruct the vents in the device casing.

Remove any dust from the device before turning it on.

Ensure that the cable installation fasteners are not damaged. Replace them, if

necessary.

Mount the device into an enclosure that meets the IP65 level of protection.

Failure to follow these instructions can result in injury or equipment damage.

WARNING

RISK OF EXPLOSION IN HAZARDOUS LOCATIONS

Verify that the power, input, and output (I/O) wiring are in accordance with Class I,

Division 2 wiring methods.

Do not substitute components that may impair compliance to Class I, Division 2.

Do not connect or disconnect equipment unless power has been switched off or the

area is known to be non-hazardous.

Securely lock externally connected units and each interface before turning on the

power supply.

Do not, connect, or disconnect USB cable unless area is known to be non-hazardous.

Potential electrostatic charging hazard: wipe the front panel of the terminal with a

damp cloth before turning ON.

Failure to follow these instructions can result in death, serious injury, or equipment

damage.

WARNING

RISK OF EXPLOSION IN HAZARDOUS LOCATIONS

Do not disconnect while circuit is live.

Potential electrostatic charging hazard: wipe the front panel of the terminal with a

damp cloth before turning ON.

Failure to follow these instructions can result in death, serious injury, or equipment

damage.

LT-4201TM/4301TM

12

English

Package Contents

Verify that all items shown in the figure are present in your package:

Legend Description Package Type

LT Unit Display Module Rear Module

1 Display module Yes Yes No

2 Rear module Yes No Yes

3 Display installation nut

(attached to the display

module)

Yes Yes No

4 Anti-rotation tee Yes Yes No

5 Socket wrench Yes No No

6 USB clamp type A Yes No Yes

7 DC power supply connector Yes No Yes

8 I/O connector 15-pin 2 No 2

9 I/O connector 6-pin 2 No 2

10 LT-4201TM/4301TM

Installation Guide

Yes No Yes

11 Warning / Caution

information

Yes

LT-4201TM/4301TM Installation Guide

13

English

Handling the LCD

If the Panel is damaged and any liquid comes in contact with your skin, immediately rinse

the area with running water for at least 15 min.

If the liquid gets in your eyes, immediately rinse your eyes with running water for at least

15 minutes and consult a doctor.

Product Label Sticker

You can identify the product version (PV) and the revision level (RL) from the product label

on the panel.

The following diagram is a representation of a typical label:

LT4200/4300 Series model which unit's version number (PV ) is 02 or later can also be used

as Rear Module.

CAUTION

SERIOUS EYE AND SKIN INJURY

The liquid present in the LCD contains an irritant:

Avoid direct skin contact with the liquid.

Wear gloves when you handle a broken or leaking unit.

Do not use sharp objects or tools in the vicinity of the LCD touch panel.

Handle the Panel carefully to prevent puncture, bursting, or cracking of the Panel

material.

Failure to follow these instructions can result in injury or equipment damage.

LT-4201TM/4301TM

14

English

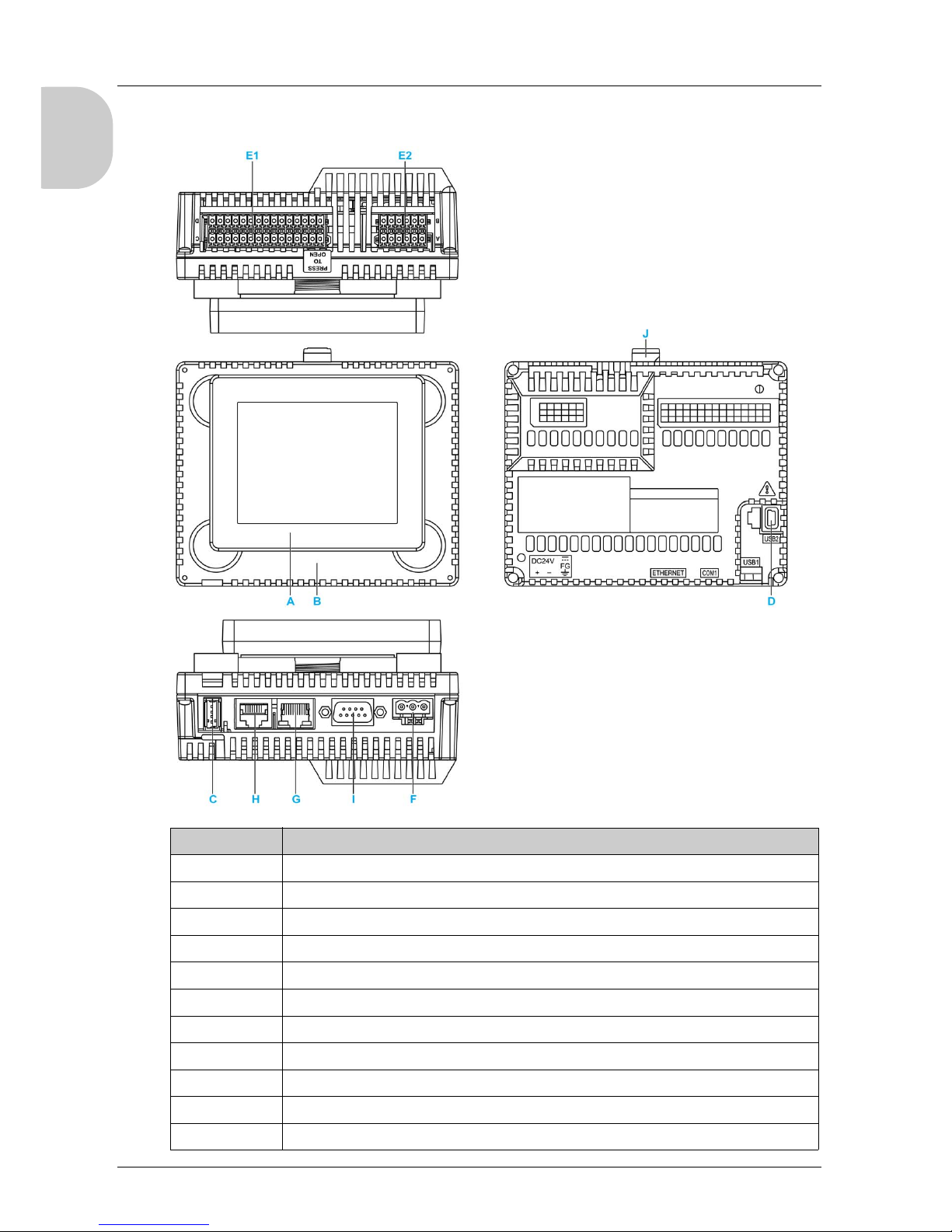

LT-4201TM/4301TM and Rear Module Parts Identification:

Part Description

A Display module

B Rear module

C USB (type A) interface connector (USB1)

D USB (mini B) interface connector (USB2)

E1 I/O terminal block 1

E2 I/O terminal block 2

F DC power supply connector

G Ethernet interface

H Serial link (RS-232C/485)

I CANopen interface

J Yellow button lock

15

LT-4201TM/4301TM Installation Guide

English

LT-4201TM/4301TM In stallation Guide

Installation

Installation

Inserting the Display Module with an Anti-Rotation Tee

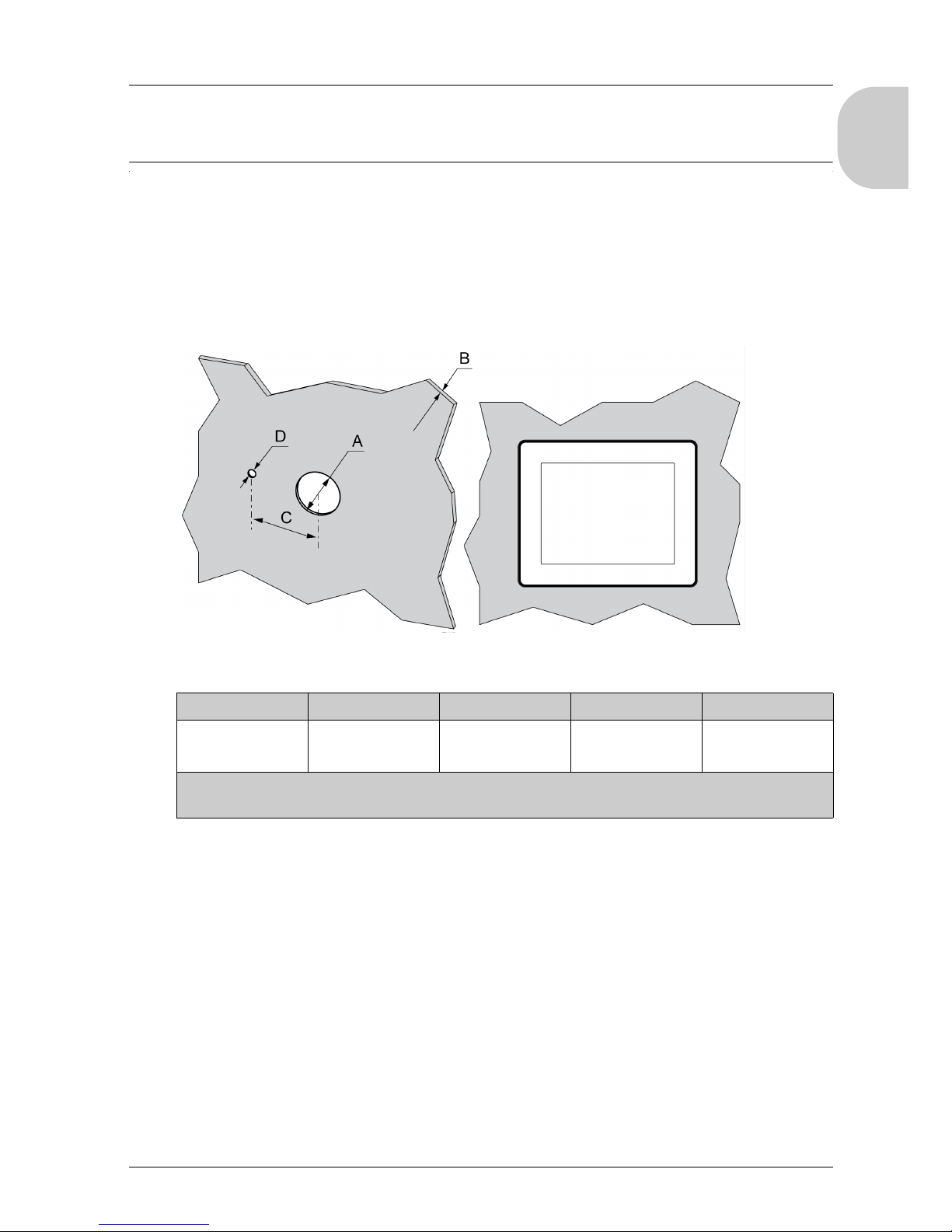

Create a panel cut-out and insert the display module into the panel from the front. The figure

shows the panel cut-out:

Dimensions

NOTE: The display module supports a rotating torque of 6 N•m (53.10 lb-in).

Without the tee option, the display module supports a rotating torque of 2.5 N•m (22.12 lb-

in).

AB (1) B (2) C D

22.500/-0.30 mm

(0.880/-0.01 in.)

1.5...6 mm

(0.06...0.23 in.)

3...6 mm

(0.11...0.23 in.)

300/-0.20 mm

(1.180/-0.0007 in.)

40/-0.20 mm

(0.150/-0.007 in.)

(1) Steel sheet

(2) Glass fiber reinforced plastics (minimum GF30)

16

English

Installing the LT Display

The figure shows the assembly:

(1) Display module

(2) Panel

(3) Display installation nut

(4) Anti-rotation tee

Installing the LT Display Module with Spacer

The spacer supplied in the accessory kit PFXZGMAK1 (sold separately), allows mounting

the product on a:

steel sheet support with a thickness between 1 and 1.5 mm (0.039 in. and 0.059 in.)

plastic support with a thickness between 1 and 3 mm (0.039 in. and 0.118 in.)

glass fiber reinforced plastic with a thickness between 2 and 3 mm (0.078 in. and

0.118 in.)

LT-4201TM/4301TM Installation Guide

17

English

The figure shows the assembly with the Panel spacer:

(1) Display module

(2) Panel

(3) Spacer

(4) Display installation nut

(5) Anti-rotation tee

Installation of the LT Unit

In order to correctly run an application on the LT, both the display module and the rear

module must be connected.

WARNING

EXPLOSION HAZARD

Do not connect or disconnect while circuit is live.

Potential electrostatic charging hazard: wipe the front panel of the terminal with a

damp cloth before turning ON.

Refer to Hardware Manual for instructions

Failure to follow these instructions can result in death, serious injury, or equipment

damage.

18

English

If you power up the rear module without connecting the display module, the logic controller

does not start and all outputs remain in the initial state. The power must be off when you

connect the 2 modules.

There are 2 ways to install the LT.

Installing the LT on the panel:

Installing the rear module on a DIN rail with a display module/rear module separation

cable:

LT-4201TM/4301TM Installation Guide

19

English

Setup Procedure

Mount the unit in an enclosure that provides a clean, dry, robust, and controlled

environment (IP65 enclosure or UL508 4x if indoors).

Before installing the LT Unit verify that:

The installation panel or cabinet surface is flat (planarity tolerance: 0.5 mm (0.019 in.)),

in good condition and has no jagged edges. Metal reinforcing strips may be attached to

the inside of the panel, near the panel cut-out, to increase the rigidity.

The panel should be designed to avoid any induced vibration resonance on the rear

module exceeding a punctual factor of 10 and to avoid any induced permanent vibration

resonance.

To reduce the resonance use the panel adaptor accessory.

The ambient operating temperature and the ambient humidity are within their specified

ranges:

Horizontal installation: 0...50 °C (32...122 °F)

Vertical installation:0...40 °C (32...104 °F)

Relative humidity: 5...85% w/o condensation (non-condensing, wet bulb

Temperature 39 °C (102.2 °F) or less)

The heat from surrounding equipment does not cause the unit to exceed its specified

operating temperature.

When installing the display in a vertical position (portrait view), the logo on the display

face must be on the right side to keep the power connector at the top:

NOTE: For use in Pollution Degree 2 environments.

20

English

The panel face is not inclined more than 30° when installing the unit in a slanted panel:

The power plug is positioned vertically when the unit is vertically installed.

The unit is at least 100 mm (3.94 in.) away from adjacent structures and other

equipment for easier maintenance, operation, and improved ventilation:

This manual suits for next models

2

Table of contents

Other Pro-face Recording Equipment manuals

Pro-face

Pro-face GP3000 Series User manual

Pro-face

Pro-face GP-4100 series User manual

Pro-face

Pro-face ST3000 Series User manual

Pro-face

Pro-face GP-4100 series User manual

Pro-face

Pro-face ST3200 Series User manual

Pro-face

Pro-face AGP-3300 Series User manual

Pro-face

Pro-face GP-2401T User manual

Pro-face

Pro-face GP-4114T User manual

Pro-face

Pro-face GP3000 Series User manual

Pro-face

Pro-face GP2000H Series User manual