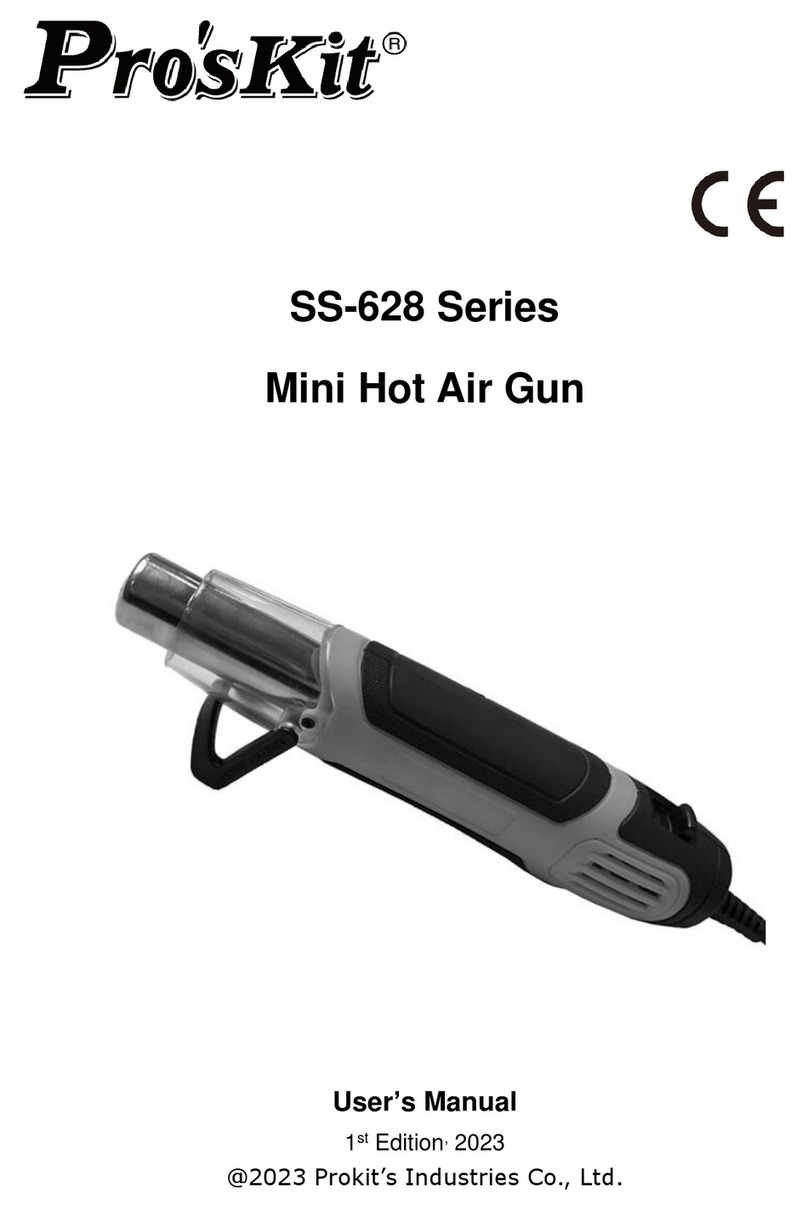

Pro's Kit SS-979 User manual

Other Pro's Kit Power Tools manuals

Pro's Kit

Pro's Kit SS-331B User manual

Pro's Kit

Pro's Kit PT-1207 User manual

Pro's Kit

Pro's Kit SS-611 User manual

Pro's Kit

Pro's Kit SI-B166 User manual

Pro's Kit

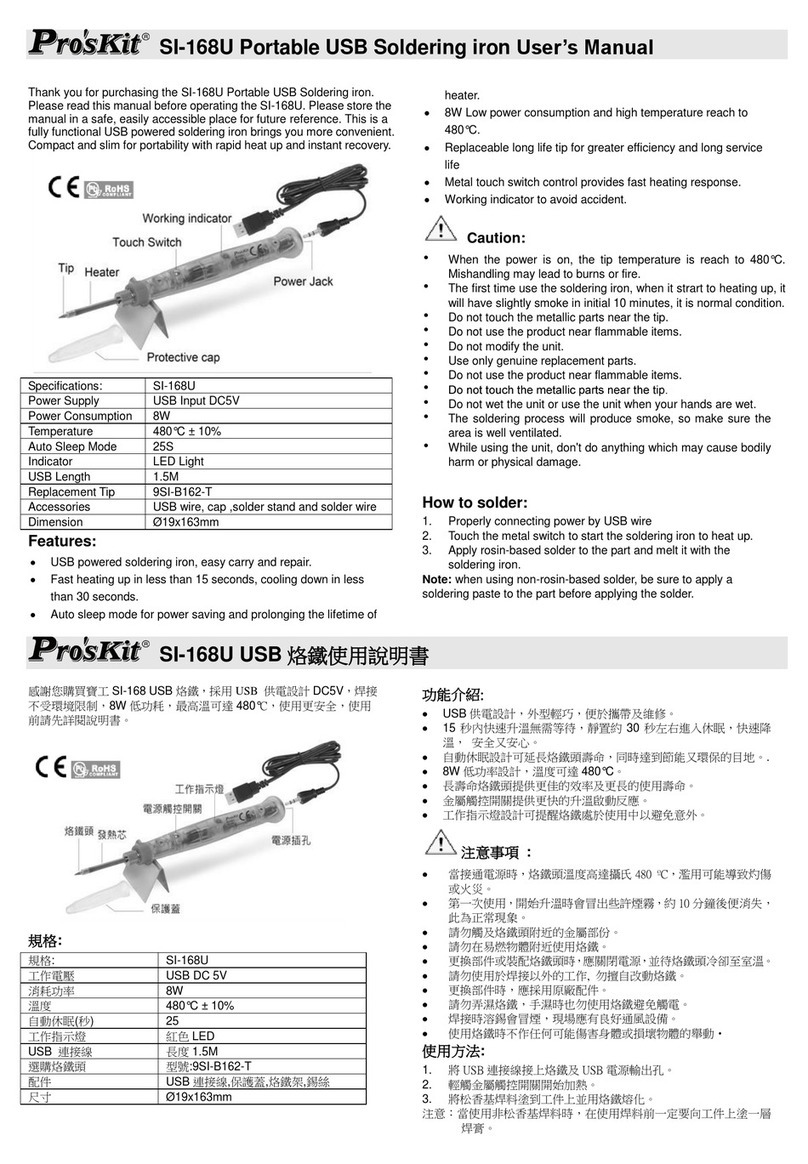

Pro's Kit SI-168U User manual

Pro's Kit

Pro's Kit PT-1362U User manual

Pro's Kit

Pro's Kit PT-0721 User manual

Pro's Kit

Pro's Kit PT-1801 User manual

Pro's Kit

Pro's Kit SI-137 User manual

Pro's Kit

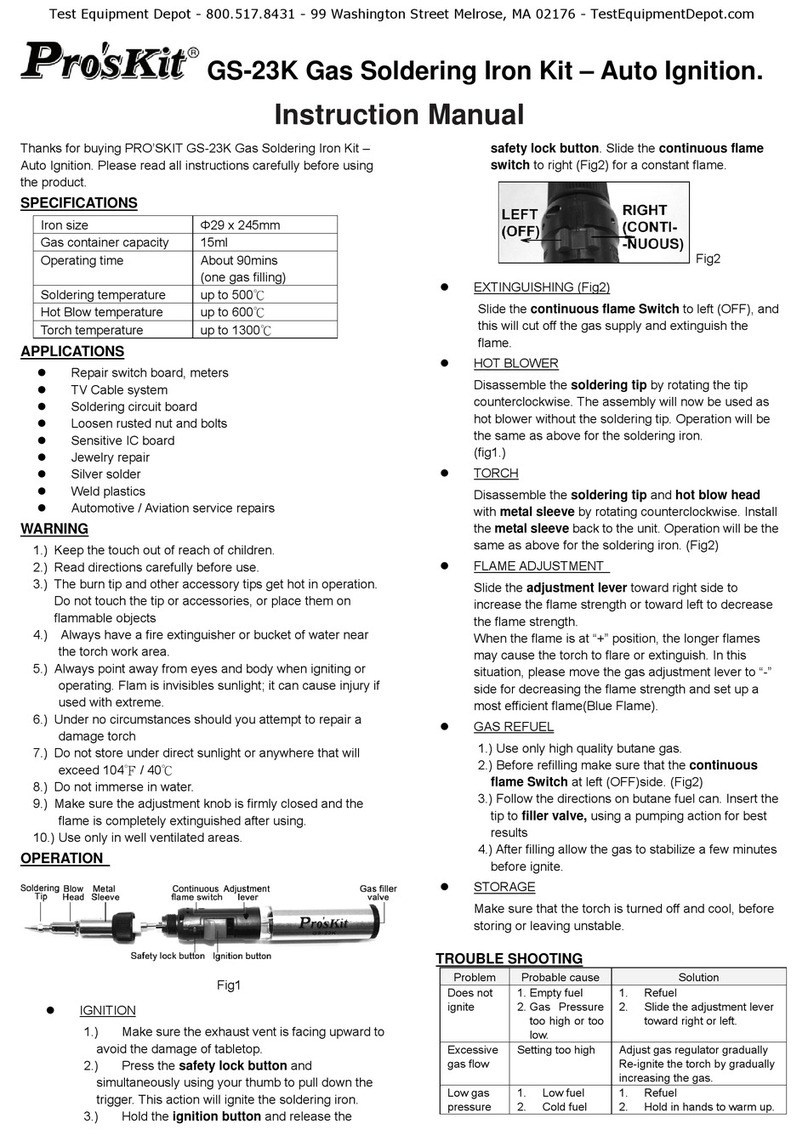

Pro's Kit GS-23K User manual

Pro's Kit

Pro's Kit PT-5501 User manual

Pro's Kit

Pro's Kit PT-1805 User manual

Pro's Kit

Pro's Kit SS-988 User manual

Pro's Kit

Pro's Kit SS-615 Series User manual

Pro's Kit

Pro's Kit SS-611A User manual

Pro's Kit

Pro's Kit PT-1806 User manual

Pro's Kit

Pro's Kit SI-168U User manual

Pro's Kit

Pro's Kit PT-5208U User manual

Pro's Kit

Pro's Kit Pro'sKt SS-621 Series User manual

Pro's Kit

Pro's Kit PT-1210 User manual

Popular Power Tools manuals by other brands

Ingersoll-Rand

Ingersoll-Rand IR106B Operation and maintenance manual

Parkside Performance

Parkside Performance PAMFWP 20-Li B2 Translation of the original instructions

Cattani

Cattani Stabil Plant-Press Operator's handbook

VATTON

VATTON 48362 manual

jbc

jbc NT105 manual

DeWalt

DeWalt XR Li-Ion DCS355-XE instruction manual