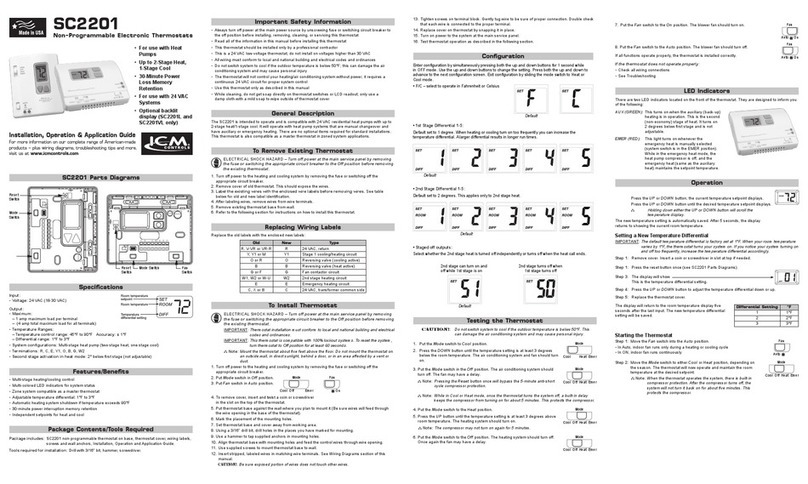

Wiring

Caution:

Electrical Hazard

All components of the control

system and the thermostat

installation must conform to

Class II circuits per the NEC Code.

Warning:

Do not overtighten terminal

block screws, as this can

damage the terminal block.

A damaged terminal block

can keep the thermostat

from tting on the subbase

correctly or cause system

operation issues.

Installation Tip

Max Torque = 6in-lbs.

Wiring

If you are replacing a thermostat,

make note of the terminal

connections on the thermostat that

is being replaced. In some cases

the wiring connections will not be

color coded. For example, the

green wire may not be connected

to the Gterminal.

Loosen the terminal block screws.

Insert wires then retighten terminal

block screws.

Place nonammable insulation into

wall opening to prevent drafts.

1.

2.

3.

Terminal Designations

C

OHeat pump changeover valve

energized in cooling

Heat pump changeover valve

energized in heating

W2 Auxiliary heat relay -Stage 2 heat

RTransformer power

GFan relay

YCompressor relay - Stage 1

heat and cool

Wiring Tips

C Terminal

The C (common wire) terminal does

not have to be connected when the

thermostat is powered by batteries.

Wire Specications

Use shielded or non-shielded 18-22

gauge thermostat wire.

Failure to disconnect the power

before beginning to install this

product can cause electrical shock

or equipment damage.

B

Common wire from system transformer

Wiring Diagrams

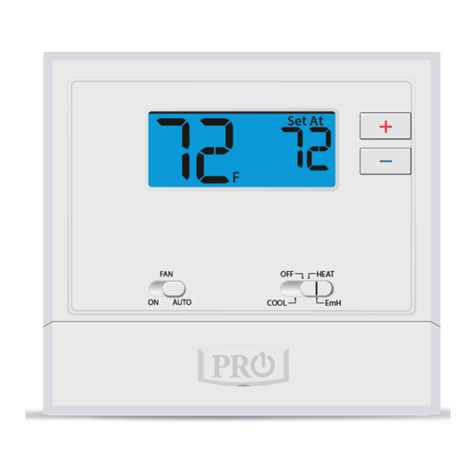

Technician Setup Technician Setup

This thermostat has 4 dierent setup congurations. To setup the

thermostat for your particular application:

1. Select COOL, HEAT, EmH, or OFF with the system switch.

2. Press and hold the + and - buttons together for 3 seconds. This

3 second delay is deigned so that homeowners do not accidentally

access the installer settings.

3. Use the + and - to change settings. Note: When you want to exit

the Technician Setup options select OFF using the system switch.

Compressor Short Cycle Delay

The compressor short cycle delay protects the compressor from “short cycling”. This

feature will not allow the compressor to be turned on for 5 minutes after it was last

turned o. Default setting is ON. Selecting OFF with the jumper pin will remove this

delay.

Tech Settings

O

This feature allows the installer

to change the calibration of the

room temperature display. For

example, if the thermostat reads

70 degrees and you would like it

to read 72 then select +2.

Room

Temperature

Calibration

(Select

System OFF)

You can adjust the room

temperature display to read

4˚above or below the factory

calibrated reading.

Cooling

Swing

(Selecting

System COOL)

0.8

The swing setting often called

“cycle rate”, “dierential”or

“anticipation”is adjustable. A

smaller swing setting will cause

more frequent cycles and a larger

swing setting will cause fewer

cycles.

The cooling swing setting

is adjustable from 0.2˚ to

2˚. For example: A swing

setting of 0.5˚will turn the

cooling on at approximately

0.5˚ above the setpoint

and turn the cooling o at

approximately 0.5˚ below

the setpoint.

The swing setting often called

“cycle rate”, “dierential”or

“anticipation”is adjustable. A

smaller swing setting will cause

more frequent cycles and a larger

swing setting will cause fewer

cycles.

The heating swing setting

is adjustable from 0.2˚ to

2˚. For example: A swing

setting of 0.5˚will turn the

heating on at approximately

0.5˚ below the setpoint

and turn the heating o at

approximately 0.5˚ above

the setpoint.

Tech Settings Adjustment Options Default

LCD Will Show

EEmergency heat relay

NOTE: In many systems with no emergency heat relay a jumper can be installed between E and W2.

Power supply

Use either O or B terminals for changeover valve.

Optional 24 VAC common connection when thermostat is used in battery power mode.

Field-supplied jumper

R

Y

C

E

G

W2

O

B

COMPRESSOR

RELAY

FAN RELAY

AUXILIARY

HEAT

COOL CHANGE

OVER VALVE

HEAT CHANGE

OVER VALVE

C

R

L2

L1(HOT)

2H/1C Heat Pump System

Typical 2H/1C Heat Pump System with seperate emergency heat

R

Y

C

E

G

W2

COMPRESSOR

RELAY

EMERGENCY

RELAY

AUXILIARY

HEAT

COOL CHANGE

OVER VALVE

HEAT CHANGE

OVER VALVE

O

B

C

R

L2

L1(HOT)

FAN RELAY

Note: In many systems

with no emergency heat

relay a jumper can be

installed between E and W2.

CA 0

Heating

Swing

(Selecting

System HEAT)

08

08 0.8

When ON, this feature turns o

the Y terminal 45 seconds after

the second stage of heat (W2)

turns on. When OFF, it allows 1st

stage (Y) and 2nd stage (W2) to

run together. (Electric for Aux)

Selectable ON or OFF.

This option should be ON

for DUAL FUEL applications

that use a gas furnace for

auxiliary heat.

Gas Auxiliary

for Heat Pump

(Selecting

System EMH)

OF OFF

6A

Swing Setting Tip

Temperature swing, sometimes called dierential or cycle rate, can be customized for

this individual application. For most applications choose a swing setting that is as

wide as possible without making the occupants uncomfortable.

Reset button.

Select For Cwith the

jumper pin.

F- Fahrenheit

C- Celsius

Select delay on

or o with the

jumper pin.

RH/R

G

Y

C

O

E

W2

RESET

B

C

F

DELAY

RH/R

G

Y

C

O

E

W2

RESET

B

C

F

DELAY