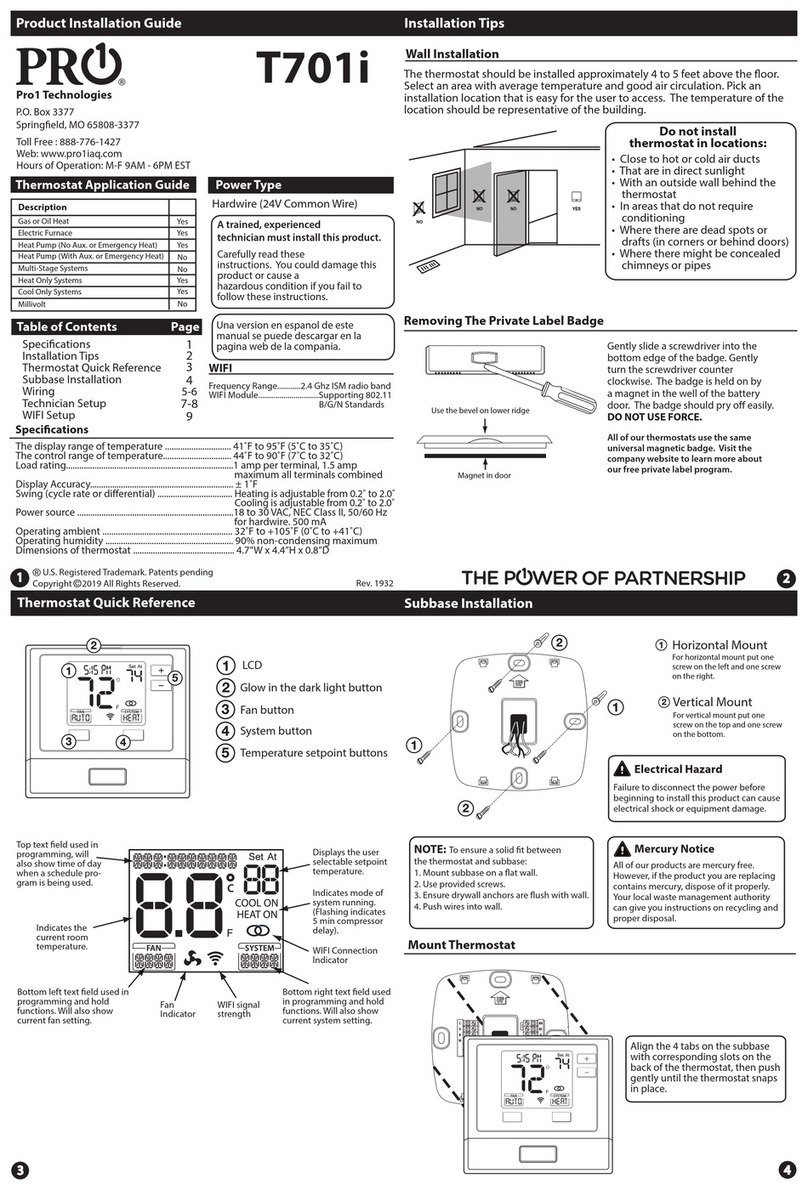

T621-2

Installation Manual

Pro1 Technologies

Toll Free : 888-776-1427

Web: www.pro1iaq.com

Hours of Operation: M-F 9AM - 6PM Eastern

Thermostat Application Guide

Description

Gas or Oil Heat

Electric Furnace

Heat Pump (No Aux. or Emergency Heat)

Heat Pump (With Aux. or Emergency Heat)

Multi-Stage Systems

Heat Only Systems

Heat Only Systems - Floor or Wall Furnace

Cool Only Systems

Millivolt

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Power Type

Battery Power

Hardwire (Common Wire)

Hardwire (Common Wire) with

Battery Backup

Table of Contents

Specications

Installation Tips

Thermostat Quick Reference

Wiring

Wiring Diagrams

Technician Setup

Page

A trained, experienced

technician must install this

product.

Carefully read these

instructions. You could damage

this product or cause a

hazardous condition if you fail

to follow these instructions.

Una version en español de este

manual se puede descargar en

la pagina web de la compañia.

Rev. 1814

Specications

The display range of temperature ... 41˚F to 95˚F (5˚C to 35˚C)

The control range of temperature.... 44˚F to 90˚F (7˚C to 32˚C)

Swing (cycle rate or dierential) ...... Heating is adjustable from 0.2˚ to 2.0˚

Cooling is adjustable from 0.2˚ to 2.0˚

Power source ...........................................18 to 30 VAC, NEC Class II, 50/60 Hz

for hardwire

Battery power from 2 AA Alkaline

batteries

Operating ambient ............................... 32˚F to +105˚F (0˚C to +41˚C)

Operating humidity .............................. 90% non-condensing maximum

Dimensions of thermostat ................. 4.7”W x 4.4”H x 1.1”D

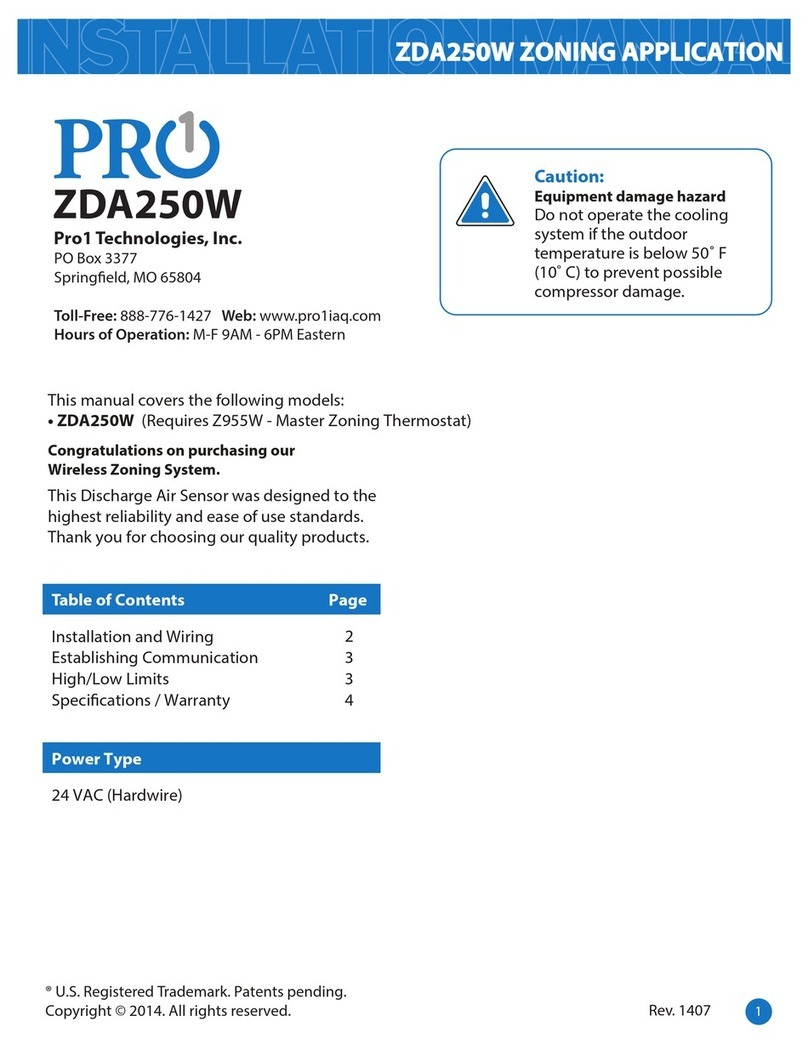

Mount Thermostat

Align the 4 tabs on the subbase with

corresponding slots on the back of the

thermostat, then push gently until the

thermostat snaps in place.

Battery Installation

Battery installation is recommended even if thermostat is hardwired

(C terminal connected). When thermostat is hardwired and batteries

are installed, the thermostat will activate a compressor delay of 5

minutes when the thermostat detects a power outage from the

hardwired power supply.

Important:

High quality alkaline batteries are recommended.

Rechargeable batteries or low quality batteries

do not guarantee a 1-year life span.

Insert 2 AA

Alkaline batteries

(included). High

quality alkaline

batteries are

recommended.

Simple

operating

instructions

are found

on the back

of the

battery

door.

Installation Tips

2-3

4

5

6

7-8

1

Installation Tips Thermostat Quick Reference

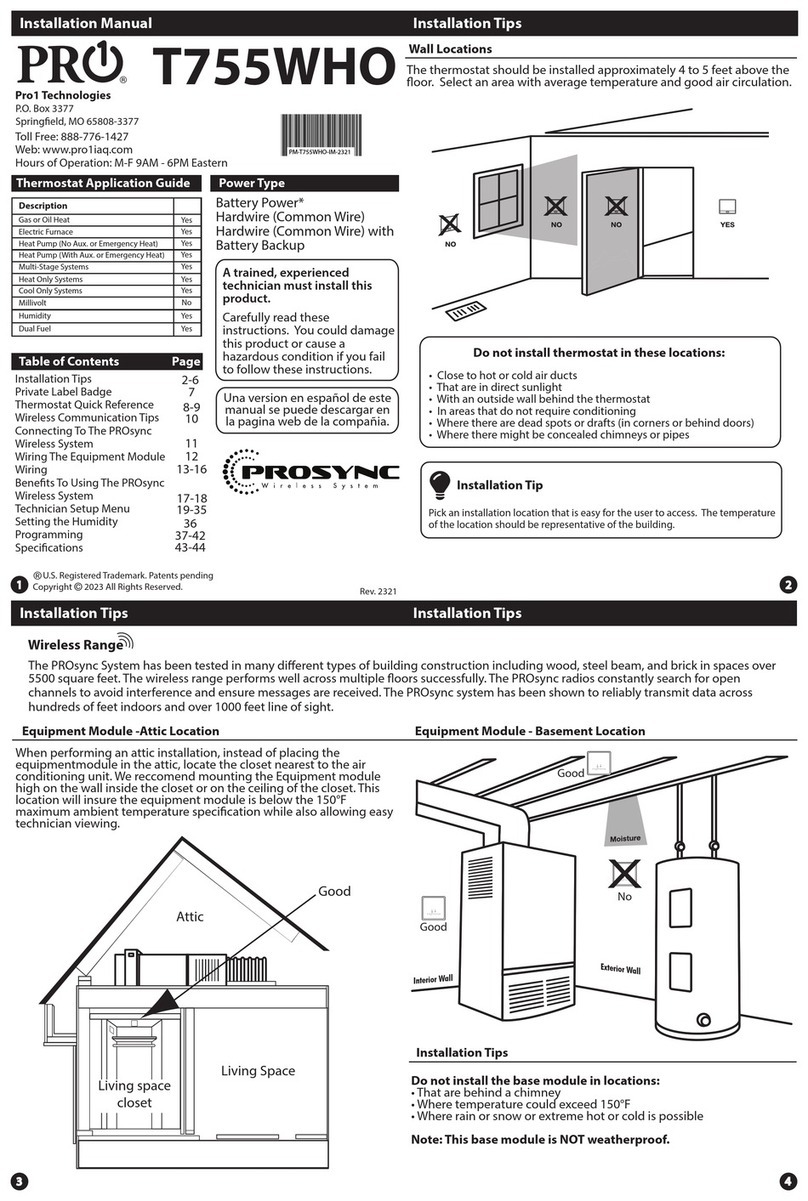

Getting to know your thermostat

Fan switch

System switch

Easy change battery door

Temperature setpoint buttons

LCD

Removing The Private

Label Badge

Gently slide a screwdriver into the bottom edge of the badge. Gently turn the screwdriver

counter clockwise. The badge is held on by a magnet in the well of the battery door. The

badge should pry o easily. DO NOT USE FORCE.

About The Badge

All of our thermostats use the same universal magnetic badge. Visit the

company website to learn more about our free private label program.

Displays the

selected setpoint

temperature.

System Operation

Indicators:

ON will display when the

COOL, HEAT or Emergency

Heat is on.

NOTE: The compressor delay feature is active

if ON is ashing. The compressor will not

turn on until the 5 minute delay has elapsed.

Low Battery Indicator:

Replace batteries when

indicator is shown.

Indicates the current

room temperature.

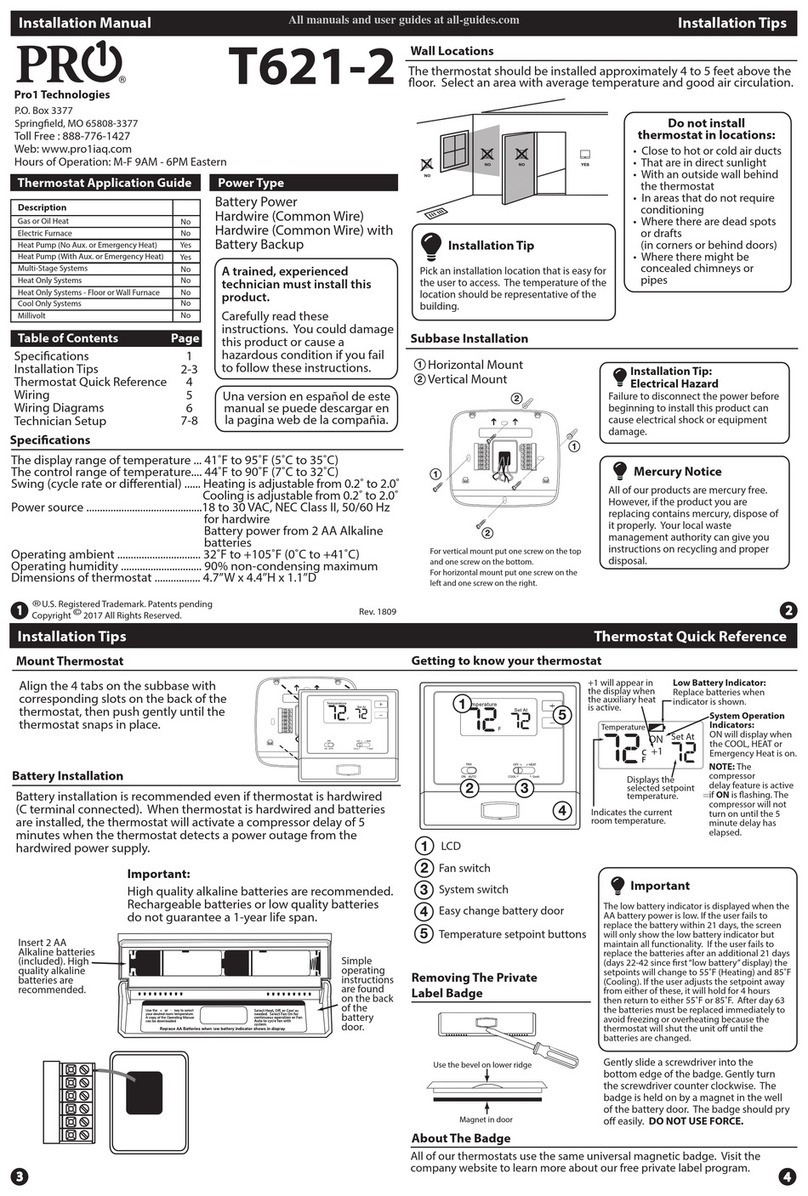

Subbase Installation

The thermostat should be installed approximately 4 to 5 feet above the

oor. Select an area with average temperature and good air circulation.

• Close to hot or cold air ducts

• That are in direct sunlight

• With an outside wall behind

the thermostat

• In areas that do not require

conditioning

• Where there are dead spots

or drafts

(in corners or behind doors)

• Where there might be

concealed chimneys or

pipes

Wall Locations

Vertical Mount

Horizontal Mount

For vertical mount put one screw on the top

and one screw on the bottom.

For horizontal mount put one screw on the

left and one screw on the right.

All of our products are mercury free.

However, if the product you are

replacing contains mercury, dispose of

it properly. Your local waste

management authority can give you

instructions on recycling and proper

disposal or you can mail the

thermostat to the address on the

warranty section for proper disposal.

Pick an installation location that is easy for

the user to access. The temperature of the

location should be representative of the

building.

Installation Tip

Mercury Notice

Do not install

thermostat in locations:

Failure to disconnect the power before

beginning to install this product can

cause electrical shock or equipment

damage.

Installation Tip:

Electrical Hazard

Magnet in door

Use the bevel on lower ridge

P.O. Box 3377

Springeld, MO 65808-3377

Conventional & Heat Pump

Conventional/Heat Pump Switch

The switch converts the thermostats

between conventional and heat pump

operation.

Heat Pump: Congures the thermostat

for heat pump operations.

Conventional: Congures the

thermostat for conventional operations.

The low battery icon is displayed when the AA

battery power is low. Whenever the thermostat

detects low battery voltage from the AA batter-

ies, the low battery icon will begin ashing on

the screen for 21 days (if the batteries are not

changed). If the batteries are not changed 22

days after the thermostat detects low battery

voltage, the thermostat screen will only show

the ashing battery icon until buttons are

pressed. If the batteries are not changed 43

days after the thermostat detects low battery

voltage, the thermostat screen will only

show the ashing battery icon until buttons

are pressed and the set points will oset to

85°F/29°C in cooling and 55°F/13°C in heating.

At this stage, set point changes can be made

temporarily but, the set points will change back

to defaulted values after a 4-hour period. The

thermostat will continue to perform this low

battery ashing, temperature oset condition

until the internal voltage threshold is reached.

When the thermostat internal voltage threshold

is reached, all relays will be opened and the

thermostat will become inoperable until new

batteries are installed.

Important

U.S. Registered Trademark. Patents pending

Copyright 2018 All Rights Reserved.