REHATEAM s.r.l.—vicolo Negrelli 5—31040 Castagnole di Paese TV - www.rehateamprogeo.com Service Manual TEKNA ADVANCE 9

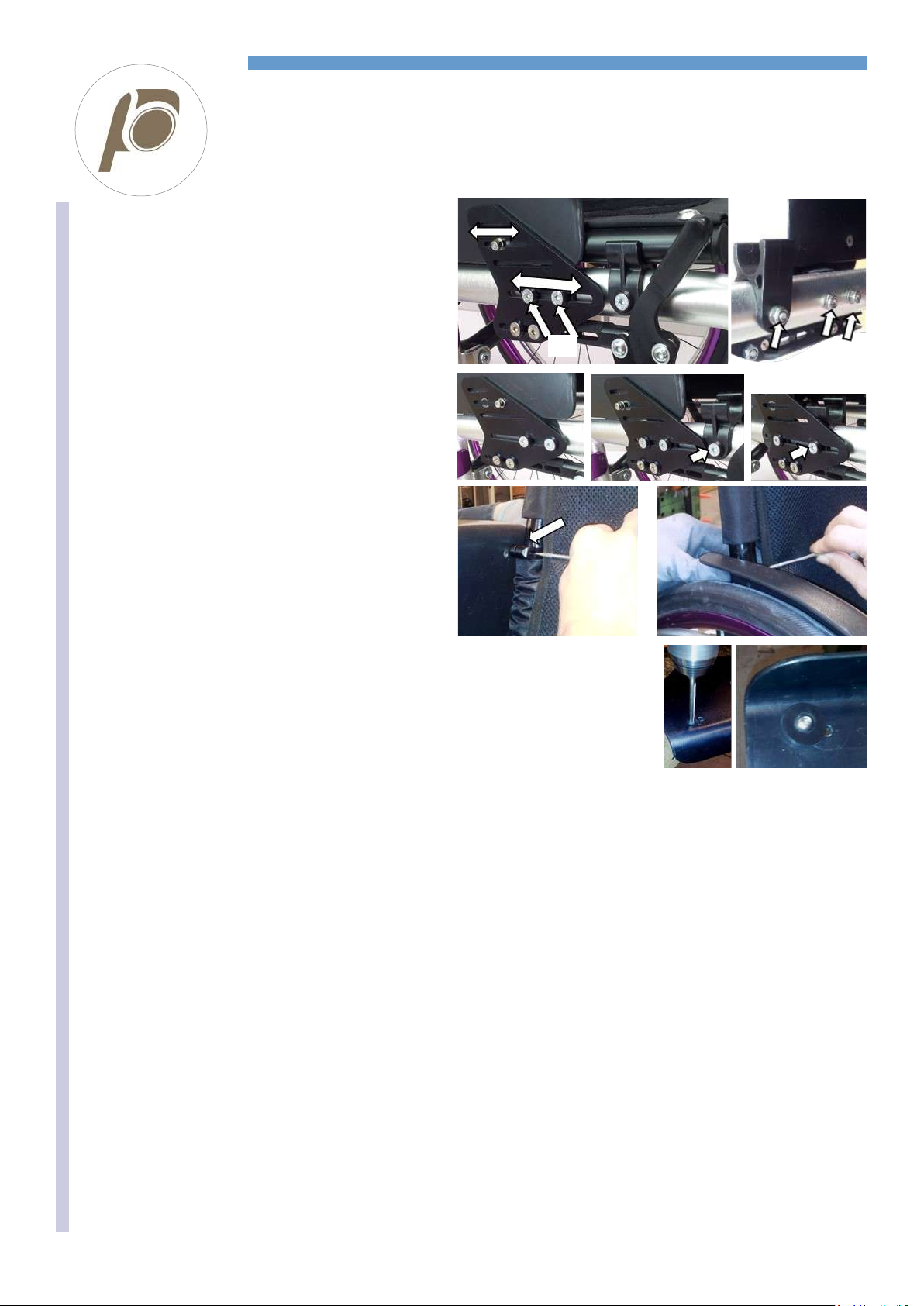

FORK ANGLE 2

system with spirit level

SERVICE MANUAL

Follows next page

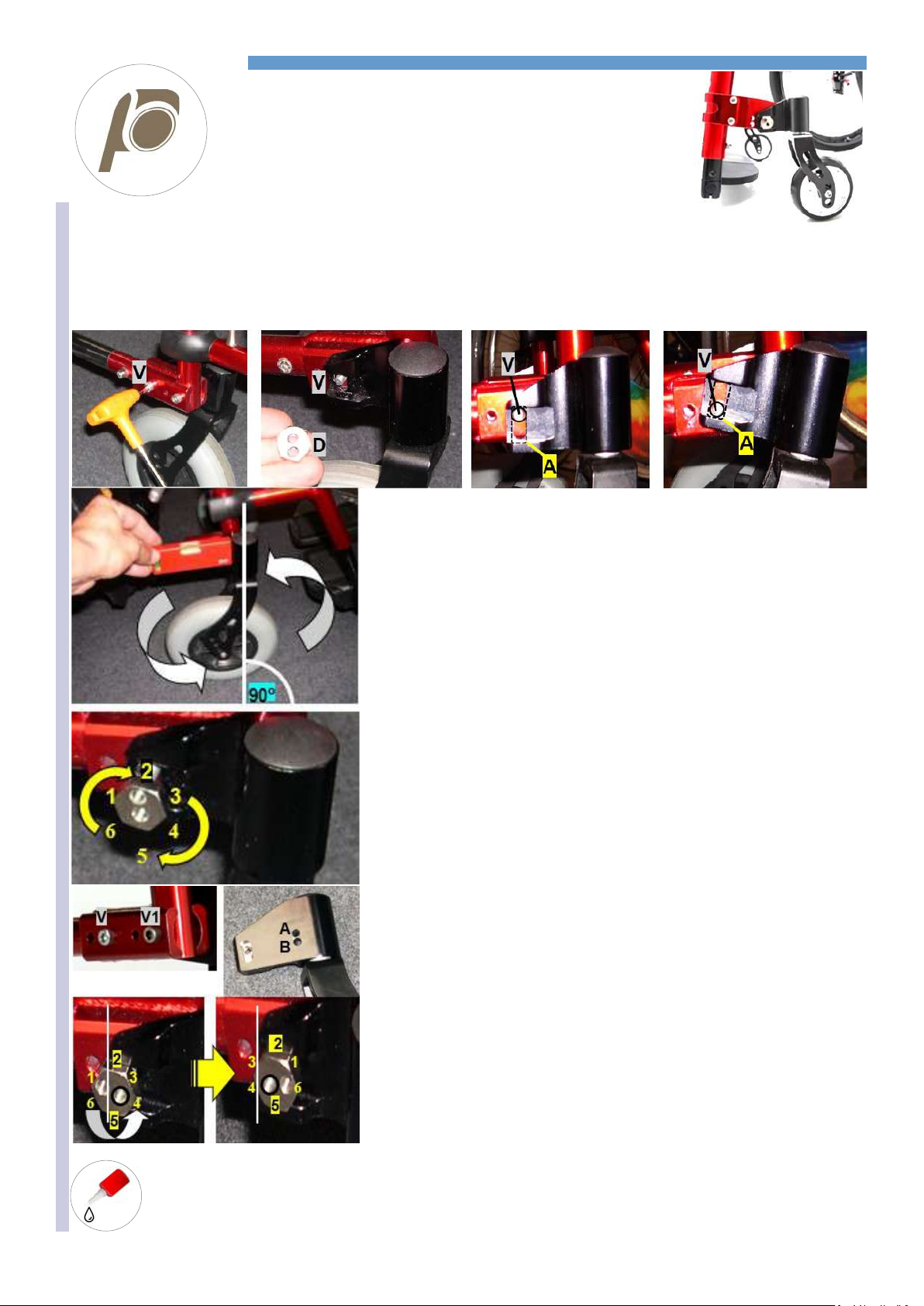

Turn the ring A1 a little in either direction and repeat the same operation above explained.

You have to repeat this procedure until the position of the ring A1 allows the bubble to be very

close to the circle of the spirit level.

At this stage, it is possible to turn both the ring A1 and the fork together with very small move-

ments until the bubble gets within the circle.

Check the nut Bis not too loose (to prevent instability of the system) and not too tighten (in this

case the ring A1 will not move).

To tighten or loosen the nut Bduring adjustment, you can usually use your finger (if it is too hard,

you can use the spanner).

As mentioned at the beginning, the adjustment is necessary whenever modifying the seat inclina-

tion (front and/or rear height).

In such cases, the entity of the adjustment is not much, in other words, the point you start from is

very near the goal. Therefore, the rotations of rings A1 and A2 will be by just a few degrees (clock

or anticlockwise).

When you reach the correct angle, fix the system. Both pins should be inserted.

With one hand, hold the fork and the pin on the hole of the ring A1 to control its position.

With the other bare hand, screw up the nut Bas much as possible while checking the spirit level.

Now gradually tighten the nut Bwith the spanner.

If, while tightening, the bubble moves away from the circle, it means that the fork has moved.

To compensate such unwanted movement, turn the fork in the nut loosening direction and check

the bubble.

It may seldom happen, though, that even the ring A1 moves while tightening. In that case, adjust it

back.

Make sure the bubble is within the circle and then fully tighten the nut B.

To reduce the risk of scratching the paint of the support around the nut, it is advisable to stick a

shaped piece of female Velcro on the spanner.

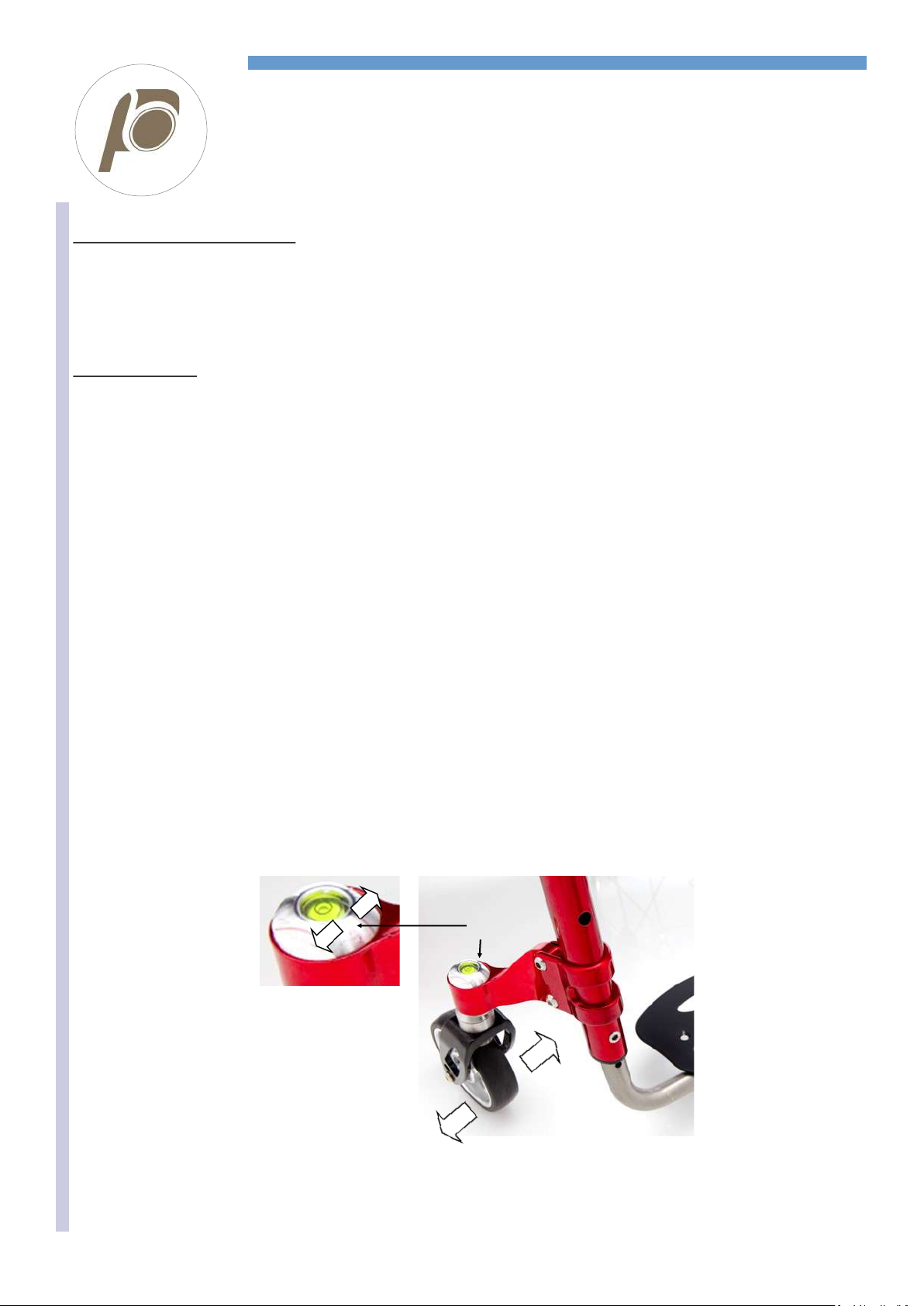

This adjustment system often allows two different combinations A1/A2 with the same correct result

(axis perpendicular to the ground).

The two positions, even though they both give the 90° to the ground, are not exactly the same, in

fact the distance between the rotation axle of the fork and the frame is different.

This means that you have to adjust the two forks symmetrically and this surely helps to adjust the

“second” fork. Just have a look where the hole of the ring A1 is with respect to the frame and sym-

metrically start form that point on the other fork to adjust.

Furthermore, the two combinations (when possible) allow solving the problem of interference be-

tween front wheel and footplate or tube. If the first found position results with such interference,

just try the second position that may be better.

Differently, it will be necessary to change the size of front wheels or footplate position or the seat

inclination (front or rear height).

Change position of A1

TURN A2

(fork)

The two white arches show the possi-

ble different positions of the fork rota-

tion axis (both at 90° to the ground).

The difference can be a few millimetres