ProMinent®

Page 8

Accessories / Notes on safety

4Accessories

WARNING

The assembly of ProMinent metering systems using third-party components which are not

verified and recommended by ProMinent is not permitted and may lead to personal injury

and damage to property for which ProMinent will not accept any liability!

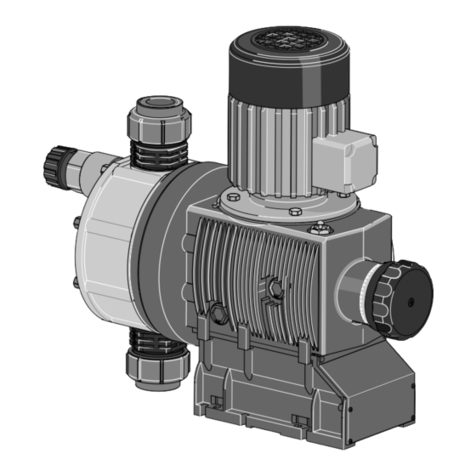

Order no. 354641 Compressed air connection union for Pneumados G 1/4A-6mm made of anodised aluminium with

gaskets, rotatable, quick coupling piece LCK 1/4"

Order no. 1030275 3/2-way solenoid valve MHE3-M1H-3/2G-QS-6-K 24Vdc

Order no. 1030277 Sound absorber UC QS-6 made of PE for solenoid valve

Order no. 1030276 Mounting angle MHE2-BG-L for solenoid valve

Order no. 1030351 Electrical pulse generator for assembly within protective housing on DIN rail pursuant to IEC/EN

60715, adjustable stroke frequency 30 –180 strokes/min., electrical connection 24Vdc / 0.6W.

Order no. 37205 Suction and metering line as well as pneumatic line made of PE 6 x 4mm (no fig.)

Foot valve with screen and non-return ball * (no fig.)

Metering valve with non-return ball * (no fig.

Order no. 1030028 Wall bracket compl. for Pneumados metering pump (no fig.

* Order number for size and material see product catalogue!

5Notes on safety

WARNING

•The pumps must be accessible any time for operation and maintenance, access may not

be hindered or blocked!

•Pneumados metering pumps can be operated with a max. permissible air pressure of 8

bar. Corresponding measures have to be taken to ensure that this pressure is not

exceeded – if required by installing a safety valve or a pressure limiting valve upstream

of the pump!

•Always rinse the liquid end first before commencing maintenance and repair work if

hazardous or unknown metering media are used!

•When metering hazardous or unknown metering media, suitable protective equipment

(goggles, gloves …) must be worn when working at the liquid end! Observe the safety

data sheets of the metering media!

•Switch off the pump control and close the compressed air supply line first before

starting any work at the pump! Always depressurise the metering line! Always empty

and rinse the liquid end! Observe the safety data sheets of the metering media!

Proper use •The pump is only designed for metering liquid media.

•All other uses or modifications are prohibited!

•The pump must not be used to meter gaseous media or solids.

•The pump is not designed for use in Ex areas.

•The pump may only be used in compliance with the technical specifications stated in the

operating instructions and in the technical data.

•The pump may only be operated if all components were installed in compliance with the

technical documentation and a proper installation was performed.

•The pump may only be operated by trained personnel.

IMPORTANT

•Settings should only be made with the pump in operation – when the adjustment pin of

the metering stroke is momentarily relieved!

•Only use the clamping rings and hose grommets specified for the corresponding hose

diameter as well as genuine hoses of the specified hose dimensions and wall thicknesses.

Otherwise, the stability of the connection is not guaranteed!

•Avoid reducing the hose sizes! In case of long lines and viscous media, the next higher

line cross-section or a pulsation dampener should be used!

BA_PN_002_07_07_GB.p65 30.07.2007, 8:07 Uhr8