Protectowire 2000 FireSystem Installation and operation manual

FIRE DETECTION CONTROL PANEL

OPERATING & MAINTENANCE MANUAL

An ISO 9001 Registered Company

APPROVED

IMPORTANT SERVICE NOTICE

When requesting service assistance, or to order parts for this

control panel, you are required to provide the Model Number,

Drawing Number and Serial Number. This product information

is recorded on the Panel Identification Label located inside the

control panel. Please have this information available before call-

ing your Authorized Protecto ire Distributor or the Factory.

60 Washington Street, Pembroke, MA 02359-1833 USA

Tel. (781) 826-3878

Fax (781) 826-2045

Visit us on the World Wide Web at:

GGG@B?D53D?G9B53?=

))5B95C9B55D53D9?>?>DB?<&1>5<

%@5B1D9>7#19>D5>1>35#1>E1<

Part Number MAN-2000

Revision Date: June 1, 2011

~ 1~

*12<5?6?>D5>DC

Page No.

$?D935 3

)/)*#)&*%$)$)*""*%$$%&(*%$

))5B95C?>DB?<&1>5<

Information and Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Standard nclosure Mounting Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

LTi2X nclosure Mounting Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

LTi4 - LTi9 nclosure Mounting Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Alarm Notification Appliance Circuit - Wire Size stimator (DS-9066) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Standby Battery - Size Calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Typical Panel Field Wire Routing Detail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Installation and System Power-Up Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Test and Maintenance Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

System Operational Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14-15

Troubleshooting - Basic Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-17

Parts Replacement - Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

)/)*##$%#&%$$*)$"-($

)ICD5=#19>?1B4 - Description, Controls and Field Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19-22

-9B55D53D?B&?G5B - Supervision . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

H@1>45B?1B4 - Description, Accommodations and Field Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24-26

?>DB?<1B4- Description, Variations and Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27-28

0?>51B4- Description, Variations and Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29-30

)/)*#%&*%$"%#&%$$*)$"-($-(&&""

%&*%$ Page No.

“A” Protectowire Alarm Point Location Meter (PDM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

“C” 16 Zone Alarm Scanner (NDS-91-16) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

“D” Waterflow Detection Card (ZC-91AW) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33-34

“ ” Switch Supervisory Card (SC-91A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

“F” Solenoid Release/Switch Supervisory Board - Field Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Solenoid Release / Detection Zone Field Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Solenoid Release Card Jumper Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

%&*%$ Page No.

“H” Intrinsic Safety Barrier for Special Hazard Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

“H” Intrinsic Safety Barrier Field Wiring Illustration (IL-1008) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

“K” Intrinsic Safety DC Isolator for Special Hazard Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

“K” Intrinsic Safety DC Isolator Field Wiring Illustration (IL-1008-2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

“L” “LL” Auxiliary Zone Alarm Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

“P” Battery Charger Status Meters (PWM-V-A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

“Q” Time Delay Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

“R” Common Alarm Signaling Relay (CAS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

“S” Common Trouble Signaling Relay (CTS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

“RR” Auxiliary Relay Module (RB-98) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

“T” Class A Alarm Notification Appliance Circuit Adapter (AM-91) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

“U” Alarm xpander Card (A -91) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

“V” Zone Voting Module (ZV-91) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

“W” Auxiliary Power Supply (PS-91) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Preaction Double Interlock Deluge Cross-Zoning - Applications Data Sheet . . . . . . . . . . . . . . . . . . . . . 50

“X” Dual Temperature Zone Card (ZC-95) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

“X” Dual Temperature Zone Card Field Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

“Y” Power Conditioning Module (PS-95) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

“Z” xternal Key Operated Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Preaction Manual Release Station and Releasing Agent Dead Man Abort . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

FS2000 Series Alarm Control Panel Instructions - To Be Mounted Adjacent to the System nclosure . . . . . . . . . . .56

Appendix A........................................................................................................................................................................

Listed Solenoids, Notification Appliance Devices, Listed Smoke Detectors...........................................................57-59

~ 2~

*12<5?6?>D5>DC(continued)

$?D935

Testing and maintenance of system controls shall be performed by competent, qualified personnel having

jurisdiction over this protective signaling system.

This system may contain detection zones which are assigned to trip release solenoids and/or equipment shut-

down. As a deterrent to accidental activation of the release system, the control card module for systems so

equipped does not have a system test (alarm simulate) button.

Testing zones with solenoid release circuits and equipment shutdown contacts may be accomplished by use

of a jumper wire across the detection/initiating circuit field wiring terminals only after all the solenoid dis-

connect switches on the release modules are depressed to the disconnect (down) position and all equipment

shutdown contacts are bypassed.

9B5?>DB?<&1>5<=ECD25D5CD54G9D816E<<I381B754,?<D21DD5BIC5D19<EB5D?4?C?=1IB5CE<D

9>CICD5=619<EB5

-1B>9>7

Fatal electrical sh ck and equipment

damage may result fr m failure t rem ve

all p wer pri r t servicing system.

~ 3~

1ED9?>

The Protectowire Co. Inc. designs and manufactures fire protection systems to meet both UL and FM Global

criteria for electrical transients introduced on both the power supply side of the system and into the panel

from field wiring for initiating device circuits, notification applaince circuits, and other external field routed

wiring.

Fire protection systems located in areas subject to lightning strikes, or subject to other severe transients, and

electromagnetic interference, should be protected similar to computers and other electronic systems with

supplemental surge and filter protection both on the power supply side and on the field wiring for initiating

device circuits, notification appliance circuits and other field routed wiring.

Please refer to surge/filter manufacturers, (eg. DIT K 800-753-2345, www.ditekcorp.com) to specify

devices for your particular conditions. The National Lightning Safety Institute (www.LightningSafety.com)

also provides valuable information regarding the problems and solutions of providing lightning protection

including assuring true earth ground conditions.

Lightning strikes, other severe power surges, and MI/RFI interference, by their nature, are beyond normal

design criteria and are outside the warranty for manufacturing defects.

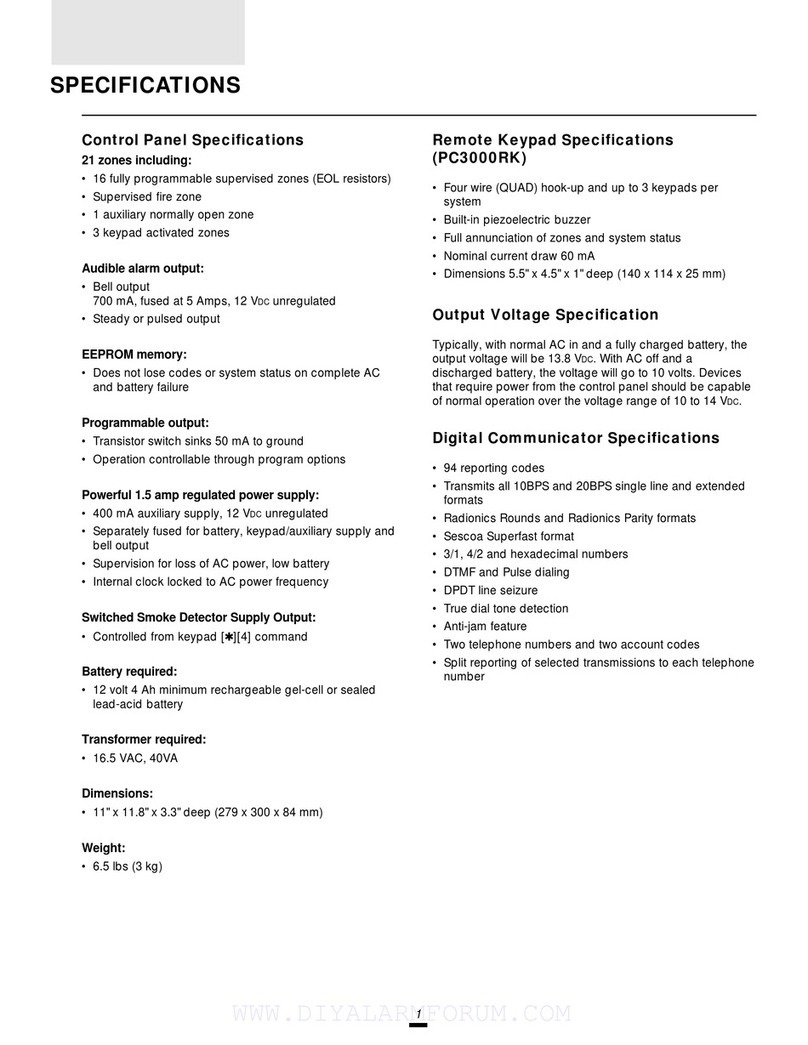

))5B95C9B55D53D9?>

5<E75&B513D9?>?>DB?<&1>5<>6?B=1D9?>1>4)@5396931D9?>C

The FS2000 Series of multiple zone fire protection panels is the latest in fire protection from The Protectowire Company, Inc. The

standard model provides, as a minimum, 2 (Class A or B) initiating device circuits and the following standard features:

- xpandable (in multiples of two zones) - Ground Fault Detection (not applicable to all systems)

- Two Supervised Notification Appliance Circuits - Alarm Lock-in until Reset

- On Board Audible Indicator Silencing - On Board System Reset Button

- Lamp and System Trouble Circuit Test - Dry Alarm and Trouble Contacts

- Initiating Device (Detection) Circuit -IDC- ALARM Test

- Monitors up to 5,000 ft. (1,524 meters) of PROT CTOWIR Linear Heat Detector Cable per circuit

- Any combination of normally open contact devices

- Accommodates up to (30) NS-series #SLR-24, #SIJ-24, #SLR-24H, Detector Identifier - HD-3

Smoke Detectors (per circuit).

- Battery Monitoring, Low or Out of operating specs. (or disconnected)

)ICD5=)@5396931D9?>C

$?D96931D9?>@@<91>359B3E9DC

N te: Circuits do NOT generate a temporal pattern signal. Appliances that can generate a temporal pattern must be employed

when a temporal pattern is required. Reference DS-9066 in this manual for compatible devices.

~ 4~

&B9=1BI&?G5B 120VAC 50/60Hz 1.75 amp maximum ** see below

)E@@?BD54)D1>42I1DD5B95C 24VDC 4.5AH minimum to 60AH maximum * see below

1DD5BI81B75B 27VDC 1.25 Fast charge, 27.6mA Max trickle charge, 12mA (typical)

&B9=1BI)ICD5=&?G5B 24V FWR by T1, 175VA typical. Greater VA rating as required by system

)ICD5=(57E<1D54&?G5B MB and B type boards provide 12 & 24VDC regulation. RS type boards

provide24VDC regulation only

?==?><1B=?>D13DC 3 amps @ 30VDC, resistive load, silenceable

?==?>*B?E2<5?>D13DC 1 amp @ 24VDC, resistive load, factory preset as non-silenceable

?==?>)E@5BF9C?BI?>D13DC 1 amp @ 24VDC, resistive load, programable

?EBG9B545D53D?B@?G5B 24VDC @ 200mA Max. used for Special Application

(non-supervised, for supervision use PSR-2040)

>F9B?>=5>D1<?@5B1D9>7

3?>49D9?>C

Ambient temperatures: 32 - 120 degree F (0 - 49 degrees C)

Humidity: Max. 95% relative non-condensing

*Battery requirements calculated per individual system demands. (See battery selection data)

**240VAC 50/60 Hz 0.85amp maximum also available. Check installation wiring diagram (IWD).

,?<D175 24 V Full wave rectified (FWR) with battery standby.

EBB5>D Two am s er circuit three am s maximum combined

Maximum two conductor copper feed cable resistance may not exceed 1 ohm (see below

1.4 Volts Maximum Line Loss

- Maximum of 500’ (feet)

- Maximum of 300’ (feet)

N- Maximum of 200’ (feet)

Note: Notification Appliance Circuits current rating may be reduced depending on

each systems current requirements. Reference the installation wiring diagram (IWD)

for individual systems actual ratings. Reference DS-9066 for more information

))5B95C9B55D53D9?>

5<E75&B513D9?>?>DB?<&1>5<>6?B=1D9?>1>4)@5396931D9?>C

(continued)

$**$(+*)

Class A (NFPA Style D)/Class B (NFPA Style A and B)

>4?6<9>5B5C9CD?B 4.7K ohm

1/2 watt

(Class B

only)

#1H9=E=6554312<5

100 ohms.

(ELR-HD-4-QC)

*/&"**%$(+*"-($

$**$,)

+C5D856?<<?G9>73?=@1D92<545F935C1@@B?F542I*85&B?D53D?G9B5?=@1>I>3

- Up to 5,000 ft. of PROT CTOWIR per circuit

- Any combination of normally open contact devices.

N te: Maximum feed cable resistance = 100 ohms Feed cable may consist of any combination

of PROT CTOWIR or copper wire.

- Up to (30) Two-Wire Smoke Detectors per circuit.

- Smoke Detectors NS-series #SLR-24V, #SIJ-24, #SLR-24H

- Detector Identifier - HD-3, Base Identifier - HB-3

N te: Smoke detectors shall not be employed on intrinsically safe detection circuits.

,?<D175)D1>42I 22VDC nominal, power limited

EBB5>DD?5>CEB51<1B= 15mA (1K ohm loop resistance minimum)

)8?BD39B3E9D3EBB5>D 35mA

)E@5BF9C9?>3EBB5>D 4.5mA

~ 5~

))D1>41B4>3<?CEB59=5>C9?>C

(all dimensions in inches)

~ 6~

nclosure Back Box Dimension Reference Table

IMPORTANT: The above stated dimensions are for the enclosure back box only and do not account for

the overall dimensions of the enclosure with the door installed. To account for the enclosure door and

hinges add an additional 0.5” to the back box width (Dimension B) and 0.1” to the back box depth

(Dimension C).

Cauti n: ?>?D4B9<<D8B?E78D85D?@?6D855>3<?CEB56?B3?>4E9D5>DBI#5D1<69<9>7C1>4?BG1D5B5>DBI

6B?=3?>4E9DCICD5=G9<<41=175CICD5=3?=@?>5>DC1>4F?94C613D?BIG1BB1>DI+C5;>?3;?EDC

@B?F94541>4C51<1<<3?>4E9D?@5>9>7C

*/& (%-) %"+#$) )&)

N2 17” 21” 4.75” 15” 19” 6” 1 2 2

N4 31” 21” 4.75” 29” 19” 6” 2 2 4

N6 31” 26” 4.75” 29” 24” N/A 2 3 6

N9 42” 26” 4.75” 40” 24” N/A 3 3 9

N12 53” 26” 4.75” 51” 24” 20” 4 3 12

N15 64” 26” 4.75” 62” 24” 29” 5 3 15

)"*9.>3<?CEB59=5>C9?>C

(all dimensions in inches)

nclosure Dimension Reference Table

*/& (%-) %"+#$) )&)

LTi2X 17.5” 19.5” 9” 12” 18.85” 21 2

N te: nclosure shown represents the LTi2X only. For LTi4 - LTi9 dimensions reference the

LTi4 -LTi9 dimensions page of this manual.

Cauti n: ?>?D4B9<<D8B?E78D85D?@?6D855>3<?CEB56?B3?>4E9D5>DBI#5D1<69<9>7C1>4?BG1D5B5>DBI6B?=

3?>4E9DCICD5=G9<<41=175CICD5=3?=@?>5>DC1>4F?94C613D?BIG1BB1>DI+C5;>?3;?EDC@B?F94541>4C51<1<<

3?>4E9D?@5>9>7C

~ 7~

A D

nclosure Dimension Reference Table

*/& (%-) %"+#$) )&)

LTi4 35.25” 24” 6.85” 34” 18” 22 4

LTi6 35.25” 29” 6.85” 34” 23” 23 6

LTi9 46.25” 29” 6.85” 45” 23” 33 9

N te: nclosure shown represents the LTi4, 6 and 9 only. For LTi2X dimensions reference the

LTi2X dimensions page of this manual.

Cauti n?>?D4B9<<D8B?E78D85D?@?6D855>3<?CEB56?B3?>4E9D5>DBI#5D1<69<9>7C1>4?BG1D5B5>DBI

6B?=3?>4E9DCICD5=G9<<41=175CICD5=3?=@?>5>DC1>4F?94C613D?BIG1BB1>DI+C5;>?3;?EDCG85>

@B?F94541>4C51<1<<3?>4E9D?@5>9>7C

)"*9"*9>3<?CEB59=5>C9?>C

(all dimensions in inches)

~ 8~

COLUMNS

A D

))5B95C<1B=9B3E9D>CD1<<1D9?>E945

)CCE54

<1B=$?D96931D9?>@@<91>359B3E9D-9B5)9J5CD9=1D?B

To ensure that all alarm notification appliance circuits will be supplied with adequate power to operate, it is

necessary to use the correct size feed cable for the distance and current requirement of each circuit. Follow the steps

below to calculate the correct wire size for your application. The calculations are based on a maximum line loss (voltage

drop) of 2 volts.

1. Calculate the required alarm device current.

(Number of Devices) X (Device Current) = Total Alarm Device Current (amps).

2. Determine the wire run distance in feet from the panel to the last alarm device.

3. Find the load current (amps) on Table 3 that best matches the required alarm device current. If the device current is in

between two values, use the higher value.

4. Find the wire run distance to the right of the device current value chosen in Step 3 which is greater than your require-

ment.

5.

The gauge at the top of the distance column is what will be required to ensure a maximum line loss of less than 2 volts.

XAMPL : If the total alarm device load is .680 amps; select .750 amps. If the measured distance is 400 ft.; select

517 ft. which is in the 14 AWG column.

AWG = AM RICAN WIR GAUG

*12<5?=@1D92<5,

&?<1B9J54)97>1<5F935C *12<5?@@5B-9B5(5C9CD1>35

%#)&(*

+- )$"%$+*%(

10 1.018

12 1.619

14 2.575

16 4.094

18 6.510

*12<5<1B=>4931D9>79B3E9D-9B5)9J5

6?B,&?<1B9J545F935C

*%%$+*%(-(

18 AWG 16 AWG 14 AWG 12 AWG 10 AWG

0.060 2550 4050 6450 10250 16350

0.125 1200 1950 3150 4900 7850

0.250 600 950 1550 2450 3900

0.375 400 650 1000 1600 2600

0.500 300 450 750 1200 1950

0.625 200 350 600 950 1550

0.750 200 300 500 800 1300

1.000 150 200 350 600 950

1.250 100 150 300 450 750

1.500 100 150 250 400 650

1.750 50 100 200 350 550

2.000 50 100 200 300 450

*%*"

,

"%

#&)

N te: the maximum alarm indicating circuit resistance is

calculated for a line loss of 2 volts divided by the maxi-

mum alarm device current.

~ 9~

DEVICE MFGR. MODEL AMPS

H24W 0.035

AMESCO HW-24 0.035

WHEELOCK MIZ 0.043

HORNS

FEDERAL 450 0.25

MBA-6-24 0.012

AMESCO MBA-8-24 0.025

MOTOR

BELLS

WHEELOCK MB 0.030

SLW24W 0.120

AMESCO SAD24 0.250

AHWP 0.100

WHEELOCK ASWP 0.113

STROBE

FEDERAL LP3SERIES 0.22

SHW24W 0.088

AMESCO SHP24 0.250

HORN/

STROBE

WHEELOCK NS4 0.361

AV1ST 0.39

STROBE/

BUZZER FEDERAL AV1 0.98

For complete list of Notification Appliance Devices and

their corresponding current draw )N&&$.N

))5B95C9B5<1B=?>DB?<&1>5<

1DD5BI)9J51<3E<1D9?>)855D

Use this form to calculate the required battery size for your system. You must first determine the duration the panel

will need to function on batteries in hours. The installation wiring diagram for your system includes a factory calculat-

ed battery size in the specification section. This calculation is based on a 24-hour backup period for non-releasing

systems and a 90 hour backup period for systems with a solenoid releasing module. An alarm duration or period of

time the system must operate in full alarm mode after the backup period has expired is assumed to be 15 minutes or

0.25 hours. This may be altered as necessary.

~ 10 ~

FORMULAS AND VARIABLES

System Standby Current in amperes = (I1) Standby Time in Hours = (H1) Battery Size De-rate Divisor = (0.85)

System Alarm Current in amperes = (I2) Alarm Time in Hours = (H2)

System Battery Size required in ampere hours – [(I1 X H1) + (I2 X H2)] / 0.85 = Battery Size (AH) Note: Use next largest size

SYSTEM STANDBY CURRENT CALCULATIONS – Enter Quantities of Installed Options only

Option DescriptionQuantityCurrent Product

&3"ASE3YSTEM8!:ONESOFDETECTIONZONESMULTIPLESOFONLYIEx8!h#vZONE!LARM3CANNERAND%XPANDERSQUANTITYBETWEENAND8!h$v7ATERFLOW:ONE#ARDQUANTITY$$x8!h%v3WITCH3UPERVISORY:ONE#ARDQUANTITIES%%x8!h&v3OLENOID2ELEASE#ARD23QUANTITIES&&x8!h5v!LARM%XPANDER#ARDQUANTITIES55x8!h6v:ONE6OTING-ODULEQUANTITIES66x8!h8v$UAL4EMPERATURE:ONE#ARDQUANTITIES88x8!h9v0OWER#ONDITIONING-ODULE/PTION9n3EE.OTE!8/THERWIRE3MOKE$ETECTORS56)2$ETECTORS3EE.OTE!8Note A:1UANTITYAND#URRENTDETERMINEDBYOFDEVICESINSTALLEDANDCURRENTRATINGOFEACHDEVICESTotal (I1)

SYSTEM ALARM CURRENT CALCULATIONS- Enter Quantities of Installed Devices only

Device Description Quantity Current Product

PDM-1000-2 Digitial Meter X 0.100A

Auxiliary Relay Module RB-98 (Option “RR”) X 0.104A

AM-91-1 Class A Alarm N.A.C. Adapter X 0.004A

Solenoid Valve (See Complete list / Current draw in Appendix A) X

Auxiliary Relays SPDT (Option “L”) X 0.015A

Auxiliary Relays DPDT (Option “LL’) X 0.035A

MB Bells (Wheelock) X 0.030A

SZ5424 Series Horn/Strobe (Amesco) X 0.250A

VALS-24 Strobe Light (Federal) X 0.080A

450 Vibratone Horn (Federal) X 0.025A

SFH Speaker / Strobe Combination (Amesco) X 0.114A

MTWP Series Horn / Strobe (Wheelock) X 0.126A

See Complete list and current draw in Appendix A

Subtotal

System Standby Current (Total I1 from Calculations above) 1 X

Total (I2)

AVAILABLE BATTERIES

Catalog # Rating (AH) Battery Cabinet

03!(.OTREQUIRED03!(.OTREQUIRED03!(.OTREQUIRED03!(%RED%"BEIGE03!(%RED%"BEIGE03!(%RED%"BEIGE2EQUIREDFOR%.ENCLOSUREn.OTREQUIREDFORLARGERSIZES

Using the tables below, fill in the appropriate quantities for the options included in your system and multiple them

with the corresponding current for each option and place the products in the product column. Add the product and

sum in the total block

SYSTEM BATTERY SIZE CALCULATIONS

[(I1 x H1) + (I2 x H2)] / 0.85=Minimum AH

[( x ) + ( x )] / 0.85= AH

H1 = 24 Hours Local H2= 0.25 Hrs Required per FM

H2 = 60 Hours Off Premise Note: Use next largest available battery size

H1 = 90 Hours Required by FM (Releasing Systems)

From the chart to the right, select the available battery size for your panel.

Other sizes are available upon request

))5B95C9B5<1B=?>DB?<&1>5<

*I@931<&1>5<-9B5(?ED9>75D19<

)

When bringing field wires to and from the control panel you must maintain segregation between Power Limited and

Non-Power Limited wiring. Use the illustration below as a guideline for routing wire within the system enclosure. Also

reference the field wiring sections of this manual to determine which field connections are Power Limited and which

are Non-Power Limited.

ALARM

NOTIFICATION

APPLIANCE

CIRCUITS

SYSTEM

AC POWER

POWER

LIMITED

DETECTION

CIRCUITS

SYSTEM BATTERY POWER

IF IN SEPARATE ENCLOSURE

TRANSFORMER

POWER

LIMITED

DETECTION

CIRCUITS

BATTERY 12VDC

IF IN SAME

ENCLOSURE

BATTERY 12VDC

IF IN SAME

ENCLOSURE

NOTE ALL POWER LIMITED WIRING

MUST BE SEGREGATED FROM POWER

LIMITED WIRING WITH A MINIMUM OF

TWO CABLE ENTRY OPENINGS AND

1/4" SPACING BETWEEN THE TWO

CONDUCTOR TYPES

NON-POWER

LIMITED

CIRCUITS

POWER

LIMITED

CIRCUITS

* POWER

LIMITED

CIRCUITS

DRY

CONTACTS

* COMMON ALARM, COMMON TROUBLE &

COMMON SUPERVISORY

DRY CONTACTS FOR CONNECTION

TO POWER LIMITED CIRCUITS ONLY

~ 11 ~

))5B95C9B55D53D9?>

&B513D9?>5<E75?>DB?<&1>5<%@5B1D9?>

>CD1<<1D9?>*5CD1>4#19>D5>1>35

>CD1<<1D9?>1>4)ICD5=&?G5B+@

1. Carefully unpack the system and inspect for any visible damage from shipping.

2. Mount the system in a clean, easily accessible, stable area with four (4) 1/4” screws. The system enclosure should be mounted

to allow clear visibility of the systems control indicators and easy access to the systems control switches.

3. Wire the system according to this manual and the Installation Wiring Diagram (IWD). Wiring should be in accordance with

applicable National and/or Local, lectrical and Fire Alarm codes. -1B>9>7DO NOT implement conduit entry through the

top of the electrical enclosure. Condensation in the conduit system could enter the enclosure and damage system components.

Where possible, use conduit entries provided. When making additional conduit entries, take measures to ensure metal drill fil-

ings and debris does not enter the components of the system. All conduit entries should be sealed to avoid water entering from

the conduit system into the system enclosure. Fai ure to comp y with the above wi void the factory warranty.

Special N te: All supervised circuits are conditioned at the factory with an end-of-line resistor ( LR-4.7K) or dummy load

resistor across the circuit field terminals. nd-of-line resistors & dummy load resistors should be removed when field wiring is

connected to the circuit terminations. Class B supervised circuits require the end-of-line resistor ( LR-4.7K) be connected at or

after the last device on the circuit. Class A supervised circuits do not require an end-of-line resistor. Solenoid Release Circuits

are conditioned with a dummy resistor across the field connections. The resistor should be removed when field wiring is con-

nected at the field terminals.

4. ?BCICD5=CG9D8C?<5>?94B5<51C539B3E9DC?><I. Ignore this step if the system does not contain solenoid releasing circuits.

Slide ALL solenoid disconnect switches to the down (disconnect) position to prevent accidental activation of solenoids.

5. Connect applicable power according to the systems rating as identified on the Installation Wiring Diagram (IWD) and on the

model ID tag mounted on the inside of the enclosure door.

a) Load connection, MOD-1 TB2 terminal “L”

b) Neutral connection MOD-1 TB2 terminal “N”

c) Ground connection MOD-1 TB2 terminal “G”

6. ?BCICD5=CG9D8C?<5>?94B5<51C539B3E9DC?><I, ignore this step if your system has no solenoid releasing circuits. System will

be in a supervisory alarm condition when powered due to the disconnection of the solenoids from Step 4. Silence the system by

pressing the “TRO./SUP. SIL.” button.

7. Disconnect dummy battery load resistor from the system battery connectors and connect standby batteries. If batteries are not

pre-charged, they will take up to 48 hours to charge to full capacity.

8.

Verify that no trouble indicators are illuminated except under the following conditions. The system has solenoid releasing circuits,

the disconnect switches are in the down (disconnect) position and the “SOL. OP N” indicator is illuminated. The batteries con-

nected to the system were not pre-charged and the “BATT. LOW” indicator is illuminated. If any other trouble lights are illuminat-

ed, determine the problem with those circuits using the troubleshooting guide in this manual and repair them before continuing.

9.

?BCICD5=CG9D8C?<5>?94B5<51C539B3E9DC?><I, ignore this step if your system has no solenoid releasing circuits. Slide all sole-

noid disconnect switches to the up (connected) position. The “AC ON” indicator should be the only system indicator illuminated.

10. Test the System per the “Test and Maintenance” Procedure in this manual.

~ 12 ~

))5B95C9B55D53D9?>

&B513D9?>5<E75?>DB?<&1>5<%@5B1D9?>

>CD1<<1D9?>*5CD1>4#19>D5>1>35

*5CD9>71>4#19>D5>1>35

Quarterly testing is advised to help ensure system controls are functioning properly. Testing should be performed by competent

personnel having jurisdiction over the protective signaling system. The following instructions should be observed in conjunction

with the System Operationa Out ine contained in this manual when testing this equipment.

1. Notify the applicable local fire department and/or alarm receiving station.

2. Inform all personnel in the facility that testing is in progress–start of testing to finish.

3. Disconnect any and all auxiliary alarm devices. (Solenoids, system shutdowns, etc.)

4. ALARM TEST–For systems equipped with a “SYS T ST” feature, Press “SYS. T ST” button located on the control panel

for approximately three seconds. The “SYST M ALARM” and all zone “ALARM” indicating lamps will illuminate indi-

cating an alarm condition for each zone. All connected alarm devices will activate. (Alarm notification appliances, relays,

etc.) Note: *89C9C1LC@5391<?B45BM651DEB5?><I.

NO TEST SYSTEMS–Systems that are configured for solenoid release DO NOT have a “SYS. T ST” button installed to

avoid accidental activation of solenoid valves. Testing of such systems may be accomplished by placing a jumper across

each detection/initiating circuits field terminals ONLY AFTER all solenoid disconnect switches on each release module

have been placed in the down (disconnect) position.

5. Press the “SYS. RST.” button located on the control panel to return to standby condition.

6. SUPERVISION TEST–Open supervised circuits (Detection, Switch Supervisory, Alarm Notification Appliance Circuits,

Solenoid, Waterflow Detection, etc.) by removing one wire lead from the field terminal for each individual circuit one at a

time. Replace each wire before moving on to the next circuit.

7. LAMP TEST–Press and hold the “LAMP/TRO. T ST” button located on the control panel. The “SYS. TROUBL / SUP.”

and “AL. SIL.” indicators will flash. All other indicators will be on steady and the trouble buzzer will pulse. Release the

button to return to standby condition.

*5CD9>7$?D5

The following L D indications will occur in addition to the system ground fault trouble when the respective circuit is

connected to earth ground.

a) The Alarm xpander card (A -91) circuits “OP N” & “SHORT” indicators will illuminate if the positive leg of the circuit

is connected to earth ground.

b) The Alarm notification appliance circuit “OP N” indicator will illuminate if the positive leg of the circuit is connected to

earth ground.

c) The Solenoid Releasing board (RS-1) circuits “TROUBL ” indicator will illuminate if the positive leg of the circuit is

connected to earth ground.

These indications are an adverse effect caused by ground faults but can prove useful in identifying the location of a

ground fault when they occur.

WARNING

*""*(")%!$'+&#$*#

#/()+"*(%#"+(*%(#%,$"%!%+*

""&%-(&(%(*%)(,$)/)*#

~ 13 ~

))5B95C9B55D53D9?>

&B513D9?>5<E75?>DB?<&1>5<%@5B1D9?>

>CD1<<1D9?>*5CD1>4#19>D5>1>35

%@5B1D9?>1<%ED<9>5

$?B=1<)D1>42I?>49D9?>

a) “AC ON” Indicator (Green) illuminated.

&?G5B)E@5BF9C9?>

@?G5BC?EB35619<EB5

a) “AC ON” Indicator (Green) OFF.

b) System trouble buzzer ON (Pulsing) - Press “SUP./TRO. SIL.” button to silence.

c) “SYS. TRO.” Indicator (Yellow) Flashing.

d) Restore AC power to resume standby condition.

@?G5BC?EB35619<EB5

a) “SYST M. TROUBL / SUP.” Indicator (Yellow) Flashing.

b) “BATT RY OUT” Indicator (Yellow) ON.

c) System trouble buzzer ON (Pulsing) - Press “SUP. / TRO. SIL.” button to silence.

d) Restore DC power to resume standby condition.

<1B=5D53D9?>9B3E9DC

)8?BD9>45D53D9?><??@45F935?B61E<D<1B=?>49D9?>

a) “SYST M ALARM” Indicator (R D) ON.

b) “ZON ALARM” Indicator (R D) ON.

c) All alarm notification appliance circuits activated. Press “AL. SIL.” button to silence, “AL. SIL.” Indicator (Yellow) Flashing.

d) Restore detection circuit or initiating device. Press “SYS. RST.” button to return to standby condition.

%@5>9>45D53D9?><??@0?>5*B?E2<5)ICD5=*B?E2<5

a) “SYST M TROUBL / SUP.” Indicator (Yellow) Flashing.

b) “ZON TROUBL ” Indicator (Yellow) ON.

c) System trouble buzzer ON (Pulsing) - Press “SUP./TRO. SIL.” button to silence.

d) Clear detection circuit to return to standby condition.

$?D96931D9?>@@<91>359B3E9DC

)8?BD9>>?D96931D9?>1@@<91>3539B3E9D<??@<)8?BD

a) “SYST M TROUBL / SUP” Indicator (Yellow) Flashing.

b) “ALARM SHORT” Indicator (Yellow) ON.

c) System trouble buzzer ON (Pulsing) - Press “SUP. / TRO. SIL.” button to silence.

d) Clear (repair) short to circuit to return to standby condition.

%@5>9>>?D96931D9?>@@<91>3539B3E9D<??@<%@5>

a) “SYST M TROUBL / SUP.” Indicator (Yellow) Flashing.

b) “ALARM OP N” Indicator (Yellow) ON.

c) System trouble buzzer ON (Pulsing) - Press “SUP. / TRO. SIL.” button to silence.

d) Clear (repair) open to circuit to return to standby condition.

)G9D38)E@5BF9C?BI0?>5

)8?BD9>CG9D38CE@5BF9C?BI39B3E9D)E@5BF9C?BI<1B=)ICD5=*B?E2<5

a) “SYST M TROUBL / SUP.” Indicator (Yellow) steady.

b) “ZON ALARM” Indicator (Yellow) ON.

c) System trouble buzzer ON (Steady) - Press “SUP. / TRO. SIL.” button to silence. System is now ready for subsequent

supervisory alarm i.e., next supervisory alarm condition will reinstate system supervisory alarm condition.

d) Press “SUP. / TRO. SIL.” button to silence.

e) Restore supervisory circuit or initiating device. Press “SYS. RST.” button to return to standby condition.

%@5>9>CG9D38CE@5BF9C?BI39B3E9D)E@5BF9C?BI*B?E2<5)ICD5=*B?E2<5

a) “SYST M TROUBL / SUP.” Indicator (Yellow) Flashing.

b) “ZON TROUBL ” Indicator (Yellow) ON.

c) System trouble buzzer ON (Pulsing) - Press “SUP. / TRO. SIL.” button to silence.

d) Repair open to return to standby condition.

~ 14 ~

))5B95C9B55D53D9?>

&B513D9?>5<E75?>DB?<&1>5<%@5B1D9?>

>CD1<<1D9?>*5CD1>4#19>D5>1>35

Operati nal Outline C ntinued:

B?E>41E<D5D53D9?>9B3E9D(Not available with Option “H”)

-85>E>45C9B12<53EBB5>D6<?GCD?7B?E>46B?=D85CICD5=@?G5BCE@@<I59D85B@?C9D9F5?B>571D9F5

a) “SYST M TROUBL / SUP” Indicator (Yellow) Flashing.

b) “GND. FAULT” Indicator (Yellow) ON.

c) System trouble buzzer ON (Pulsing) - Press “SUP / TRO. SIL.” button to silence.

d) Repair Ground Fault and allow 5 seconds for system to restore to standby condition.

-1D5B6<?G5D53D9?>9B3E9D

%@5>9>G1D5B6<?G45D53D9?>39B3E9D0?>5*B?E2<5)ICD5=*B?E2<5

a) “SYST M TROUBL / SUP” Indicator (Yellow) Flashing.

b) “ZON TROUBL ” Indicator (Yellow) ON.

c) System trouble buzzer ON (Pulsing)

d) Press “TRO. SIL NC ” button to silence.

e) Repair Open to return to standby condition.

)8?BD9>G1D5B6<?G45D53D9?>39B3E9D-1D5B6<?G<1B=)ICD5=<1B=

a) “SYS. AL.” Indicator (Red) ON.

b) “ZON AL.” Indicator (Red) ON.

c) All alarm notification appliance circuits activated. - Press “AL. SIL.” button to silence, “AL. SIL.” indicator (Yellow) flashing.

d) Restore waterflow circuit or initiating device. Press “SYS. RST.” button to return to standby condition.

)?<5>?94(5<51C5)E@5BF9C9?>9B3E9D

)8?BD9>B5<51C9>739B3E9D)?<5>?94)8?BD

a) “SYST M TROUBL / SUP” Indicator (Yellow) Flashing.

b) “SOL NOID SHORT” Indicator (Yellow) ON.

c) System trouble buzzer ON (Pulsing)

d) Press “SUP. / TRO. SIL.” button to silence.

e) Repair short to return to standby condition.

%@5>9>B5<51C9>739B3E9D)?<5>?94%@5>

a) “SYST M TROUBL / SUP” Indicator (Yellow) Flashing.

b) “SOL NOID OP N / DISC.” Indicator (Yellow) ON.

c) System trouble buzzer ON (Pulsing).

d) Press “SUP. / TRO. SIL.” button to silence.

e) Repair open to return to standby condition.

*B9@13D9F1D9?>?6B5<51C9>739B3E9D5D5B=9>542IJ?>5@B?7B1==9>7

a) 24 VDC or 24FWR supplied at solenoid terminals. (factory set)

H@1>454<1B=$?D96931D9?>@@<91>359B3E9D

Short in alarm notification appliance circuit:

a) ““SYST M TROUBL / SUP”.” Indicator (Yellow) Flashing.

b) Alarm xpander “AL. TROUBL SHORT” indicator (Yellow) ON.

c) System trouble buzzer ON (Pulsing) - Press “SUP. / TRO. SIL.” button to silence.

d) Repair short to return to standby condition.

%@5>9><1B=>?D96931D9?>1@@<91>3539B3E9D

a) ““SYST M TROUBL / SUP”” Indicator (Yellow) Flashing.

b) Alarm xpander “AL. TROUBL OP N” indicator (Yellow) ON.

c) System trouble buzzer ON (Pulsing) - Press “SUP / TRO. SIL.’ button to silence.

d) Repair Open to return to standby condition.

*B9@13D9F1D9?>?6H@1>454<1B=$?D96931D9?>@@<91>359B3E9D

a) Alarm xpander “ALARM” Indicator (Red) ON.

b) Alarm notification appliances operating - audible/visual devices

c) Press “Alarm xpander Silence” button to silence.

d) Clear Alarm and press “SYS. RST.” to return to standby condition - 9B3E9D=ECD25C9<5>354@B9?BD?B5C5D.

~ 15 ~

))5B95C9B55D53D9?>

&B513D9?>5<E75?>DB?<&1>5<%@5B1D9?>

>CD1<<1D9?>*5CD1>4#19>D5>1>35

~ 16 ~

C ntinued n next page

Basic Troubleshooting Guide for The FS2000 Series Fire Alarm Control Panel

Indicator Status Fault Condition Course of Action Alternate Action

Primary

“A.C. ON” Indicator OUT

“SYS. TROUBLE / SUP.” Indicator

flashing

Trouble Buzzer Pulsating

AC Power source failure Check AC power source

Connections and voltage

Reset Circuit breaker CB1

Located on the Main Board.

Check AC voltage across

terminals JX 3 and 4 of

the Main Board. If

approximately 30 VAC

replace control card (CC-

91A). If not, check the

transformer and

connections

“A.C. ON” Indicator ON

“SYS. TROUBLE / SUP”

Indicator flashing

“BATTERY OUT’ Indicator ON

Trouble Buzzer Pulsating

Backup Power source

failure

Batteries disconnected or

overcharged

Check the battery

connections.

Check battery fuse F3

On Main Board

Check battery voltage

with charger connected.

Voltage should be

between 26-28 volts.

Replace batteries if

needed.

Standby Power

“A.C. ON” Indicator ON

“SYS. TROUBLE / SUP.” Indicator

flashing

“BATTERY LOW” Indicator ON

Trouble Buzzer Pulsating

Backup Power source

failure

Batteries undercharged or

drained below acceptable

voltage level of

approximately 20.4 VDC

Check the battery voltage and

be sure to allow at least 48

hours for charging of new or

drained battery sets. If

batteries do notcharge,

replace them.

If battery voltage is

above acceptable voltage

level, replace control

card (CC-91A)

“A.C. ON” Indicator ON

“SYS. TROUBLE / SUP.” Indicator

flashing

“AL SHORT” Indicator ON

Trouble Buzzer Pulsating

Alarm Notification

Appliance Circuit fault. A

short exists in the Alarm

Notification Circuit field

wiring.

Remove the Alarm

Notification Appliance Circuit

field wiring from the field

terminals and replace with an

end-of-line resistor 4.7K ohm

½ W. (ELR-4.7K). If the

condition clears, fault is

located in the field wiring.

Find and replace short.

If condition does not

clear, replace the control

card (CC-91A)

Alarm Notification Appliance Circuits

“A.C. ON” Indicator ON

“SYS. TROUBLE / SUP.” Indicator

flashing

“AL OPEN” Indicator ON

Trouble Buzzer Pulsating

Alarm Notification

Appliance Circuit fault. A

open exists in the Alarm

Notification Circuit field

wiring

Remove the Alarm

Notification Appliance Circuit

field wiring from the field

terminals and replace with an

end-of-line resistor 4.7K ohm

½ W. (ELR-4.7K). If the

condition clears, fault is

located in the field wiring.

Find and replace open.

If condition does not

clear, replace the control

card (CC-91A)

Ground Fault

“A.C. ON” Indicator ON

“SYS. TROUBLE / SUP.” Indicator

flashing

“GND FAULT” Indicator ON

Trouble Buzzer Pulsating

A ground fault exists.

Either a Positive or

Negative connection exists

to earth ground in the

system or its field wiring.

All field wiring must be

tagged and removed from the

field terminals until condition

clears or all wiring has been

isolated. If condition clears

after removing a field wire,

fault(s) exists in that wire.

Repair fault and reconnect all

field wiring.

If after all field wiring is

isolated from the panel

the condition still exists,

consult factory.

Detection Circuits

“A.C. ON” Indicator ON

“SYS.TROUBLE / SUP.” Indicator

flashing

“ZONE TROUBLE” Indicator ON

Trouble Buzzer Pulsating

(includes detection, waterflow and switch

supervisory zones)

Open in zone circuit field

wiring. Class B – Remove the Zone

Circuit field wiring from the

field terminals and replace

with an end-of-line resistor

4.7K ohm ½ W. (ELR-4.7K)

across the (+) and (-) out

terminals. Class A–place

jumpers across the field

terminals in a Class A

configuration. If the condition

clears fault is in the field

wiring. Find and repair open.

If the circuit does not

clear when conditioned

as stated previously,

replace the Zone Card

(ZC-91A). If the problem

still persists, consult the

factory.

* Impedance < .1 ohm

~ 17 ~

C ntinued fr m previ us page

Basic Troubleshooting Guide for The FS2000 Series Fire Alarm Control Panel

Indicator Status Fault Condition Course of Action Alternate Action

Detection Circuits

“A.C. ON” Indicator OUT

“SYS. ALARM” Indicator ON

Zone “ALARM” Indicator ON

Short in zone circuit field

wiring or initiating device in

alarm i.e., Smoke detector,

Linear heat detector, etc.

Class B – Remove the Zone

Circuit field wiring from the

field terminals and replace

with an end-of-line resistor

(ELR-4.7K) across the (+) and

(-) out terminals.

Class A-Place jumpers across

the field terminals in a Class

A configuration. Depress the

“SYS. RST” button. If the

condition clears, fault is in the

field wiring. Find and repair

short or initiating device.

If the circuit does not

clear when conditioned

as stated previously,

replace the Zone Card

(ZC-91A). If the problem

still persists, consult the

factory

“A.C. ON” Indicator ON

“SYS. TROUBLE / SUP”

Indicator flashing

“SOLENOID “TROUBLE / DISC.”

Indicator ON

Trouble Buzzer Pulsating

Solenoid Release Circuit

fault. An open exists in the

solenoid release circuit field

wiring.

Check Solenoid Release

Circuit fuse F1 on Release

Card. Check that “SOL.

DISC. SWITCH” is in the up

(connect) position. Check

Solenoid Release Circuit Field

wiring for continuity.

After removing field

wiring, simulate a

solenoid connection by

placing a 1K, 1W resistor

across the field wiring

terminals. If condition

does not clear consult the

factory.

Solenoid Release

“A.C. ON” Indicator ON

“SYS. TROUBLE / SUP.” Indicator

flashing

“SOLENOID “TROUBLE / DISC.”

Indicator ON

Trouble Buzzer Pulsating

Solenoid Release Circuit

fault. An short exists in the

solenoid release circuit field

wiring.

Check the solenoid coil for a

short by disconnecting it and

checking that its resistance is

within tolerance. Check field

wiring for a short circuit.

After removing field

wiring, simulate a

solenoid connection by

placing a 1K, 1W resistor

across the field wiring

terminals. If condition

does not clear consult the

factory.

“A.C. ON” Indicator ON

“SYS. TROUBLE / SUP.” Indicator

flashing

Alarm Expander Card -

“AL. TROUBLE OPEN” Indicator ON

Trouble Buzzer Pulsating

Alarm Expander Notification

Appliance Circuit fault. An

open exists in the Alarm

Expander Circuit field

wiring.

Check fuse F7 located on the

Alarm Expander Card. Check

the field wiring for continuity.

Replace fuse or repair open in

field wiring as required.

Class B – Remove the

field terminals and

replace with an end-of-

line resistor (ELR-4.7K)

across the (+) and (-) out

terminals.

Class A– Place jumpers

across the field terminals

in a Class A

configuration. If the

condition clears, fault is

in the field wiring. Find

and repair open.

Alarm Notification Appliance Circuits

“A.C. ON” Indicator ON

“SYS. TROUBLE / SUP.” Indicator

flashing

Alarm Expander Card -

“AL. TROUBLE SHORT” Indicator

ON

Trouble Buzzer Pulsating

Alarm Expander Notification

Appliance Circuit fault. A

short exists in the Alarm

Expander Circuit field wiring.

Class B – Remove the field

terminals and replace with an

end-of-line resistor (ELR-

4.7K) across the (+) and (-)

out terminals.

Class A– Place jumpers

across the field terminals in a

Class A configuration. If the

condition clears, fault is in the

field wiring. Find and repair

short.

Check for faulty Alarm

Notification Appliance

device. If condition does

not clear with circuit

conditioned at the field

terminals as described

previously, replace the

Alarm Expander Card

(AE-91).

))5B95C9B55D53D9?>

&B513D9?>5<E75?>DB?<&1>5<%@5B1D9?>

>CD1<<1D9?>*5CD1>4#19>D5>1>35

This manual suits for next models

1

Table of contents