3

6. Switch on DC supply (red LED shall flashes; signalization of operation start)

7. Program the button mode (see programming procedure).

8. Screw the button using two screws.

9. Perform functional tests.

3. Opt cal s gnal zat on.

The button is equipped with the LED that indicates operations or programming status.

• LED- red:

- alarm status: permanently illuminated

- countdown of abort time or supply restart: flashes

- programming: go to programming procedure

4. Programm ng.

4.1. Programm ng descr pt on.

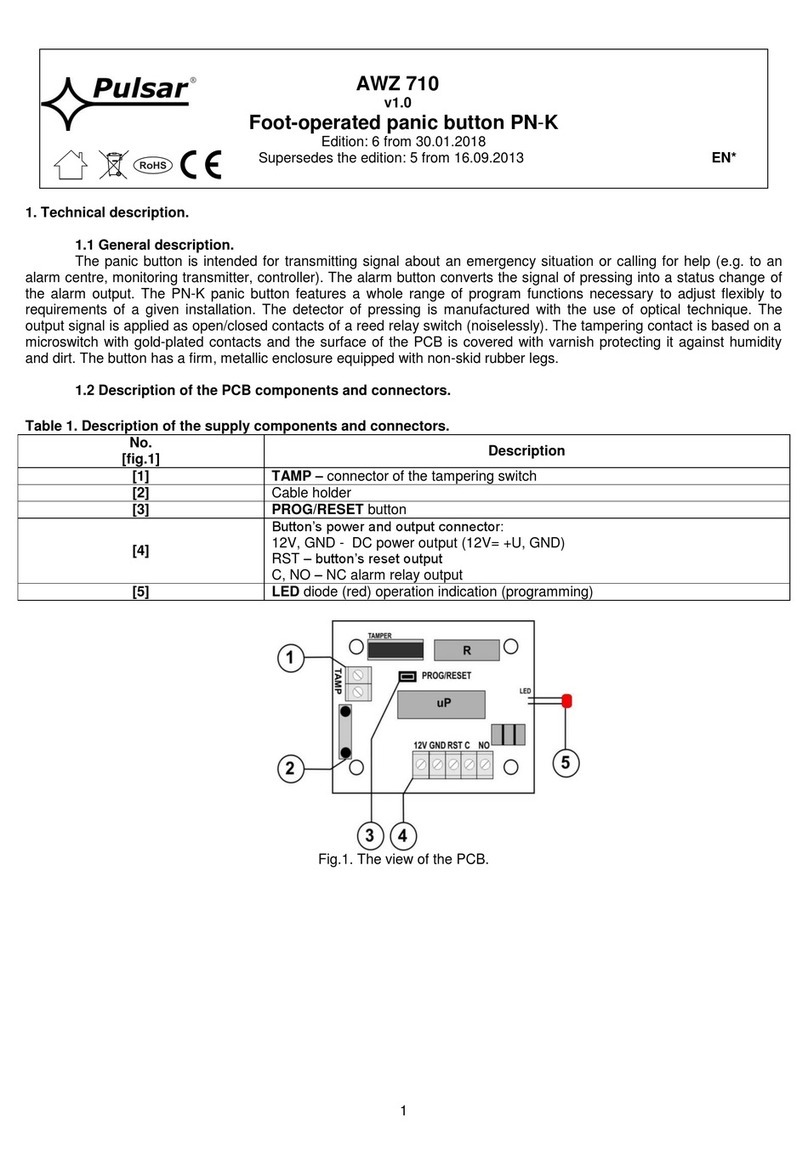

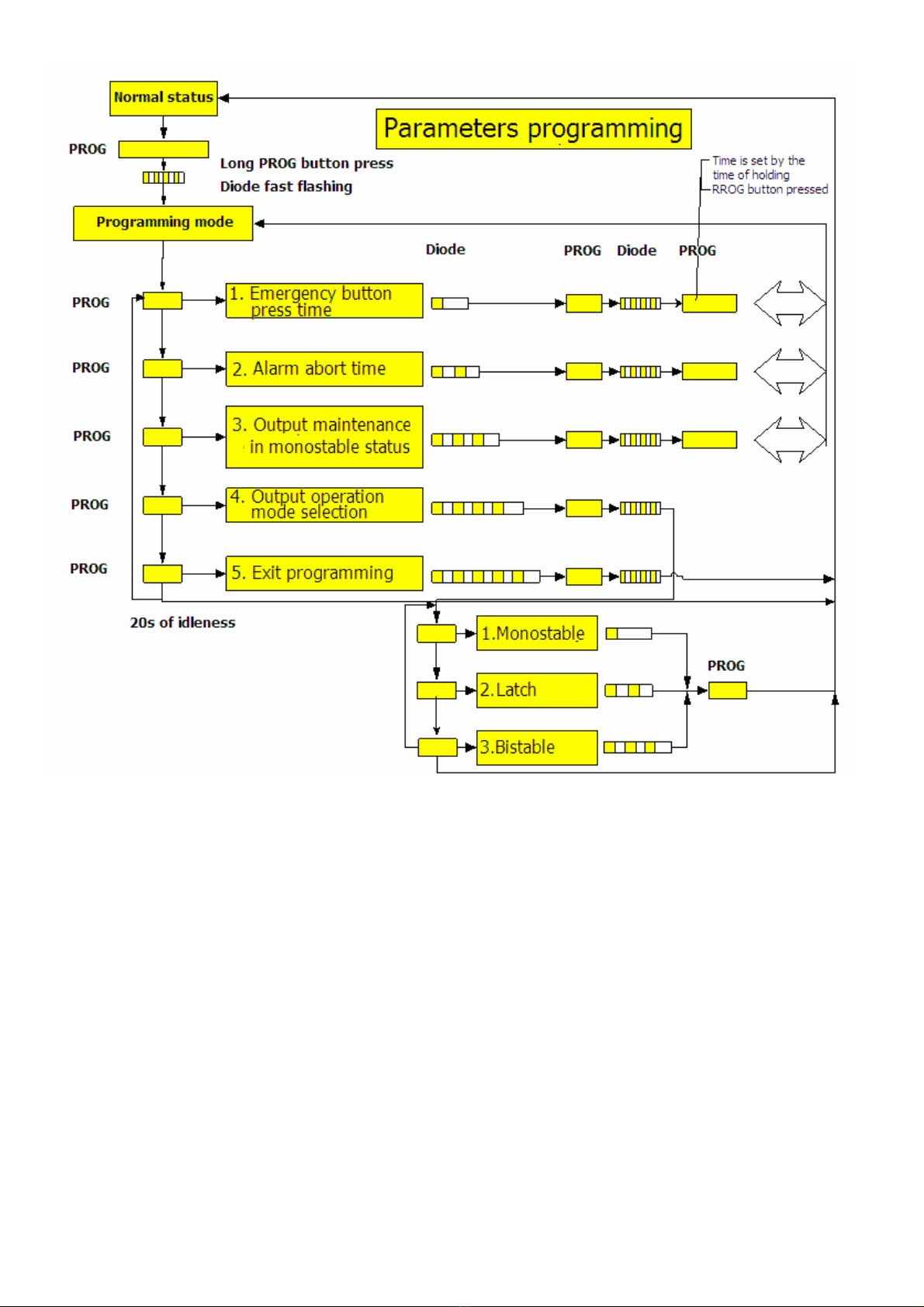

Enter programming mode: press PROG/RESET button for about 5 sec. The diode starts flashing fast in this

mode short button press selects parameters we want to edit the number of active parameter is signalized by LED

flashes. To confirm program choice press PROG/RESET button for about 3 sec the choice is confirmed by short flashes.

Not ce!

If the button s not pressed n 20s, dev ce w ll ex t the programm ng mode w thout sav ng the sett ngs.

Programs:

1. Emergency button press time.

2. Alarm abort time.

3. Back-up time in the monostable mode.

4. Output operation mode selection.

5. Exit programming mode.

Program 1: emergency button press t me.

In the main menu (LED x 1) press PROG/RESET button for about 3s. Then press and hold PROG button for a

desired period of time (LED = flashes). Button press time is the time of parameter that is being programmed. After button

release time length is saved in the device memory and the device returns to the “main menu”.

Factory presets: 1s.

Program 2: alarm abort t me.

In the main menu (LED x 2) press PROG/RESET button for about 3s. Then press and hold PROG button for a

desired period of time (LED = flashes). Button press time is the time of parameter that is being programmed. After button

release time length is saved in the device memory and the device returns to the “main menu”.

Alarm abort time is the time that is counted down (LED = flashes) after the first button press if the time is not

equal to 0s. Alarm action does not occur when during the abort time the button is pressed again.

Factory presets: 0s.

Program 3: back-up t me n the monostable mode.

In the main menu (LED x 3) press PROG/RESET button for about 3s. Then press and hold PROG button for a

desired period of time (LED = flashes). Button pressed time is the time of parameter that is programmed. After button

release time length is saved in the device memory and the device returns to the “main menu”.

Factory presets: 2s.

Program 4: output operat on mode select on.

In the main menu (LED x 4) press PROG/RESET button for about 3s. Then press the PROG button for a short

period of time and the diode will indicate loop selection. (LE= 1 2 3: operation mode).

- monostable (LED x1) = active output during the time set in 3 program

- latch (LED x2) = active output till reset time via RTS inut or PROG/RESET button

- b stable (LED x3) = output changes status after every button press

In order to confirm the mode press and hold the PROG button for about 3s or wait 20s. (20s idle state).

Factory presets: monostable mode.

Program 5: ex t programm ng mode.

In the main menu (LED x 5) press PROG button for about 3s. The button quits the programming mode and saves

the settings.