5

P: 479.419.4800 | F: 479.419.4801 | www.purkeys.net

LIFTGATE DOUBLE CHECK USER GUIDE

OPERATING INSTRUCTIONS

e Double Check can use any available vehicle as a power source (i.e. car,

tractor), as long as the vehicle has a 12 V battery and an alternator. However,

if a tractor is being used as the source, it is critical that you ensure that no

part of the tractor is touching the trailer—it cannot be coupled with, or even

touching, the trailer—as the 5th wheel ground path will cause inaccurate test

results.

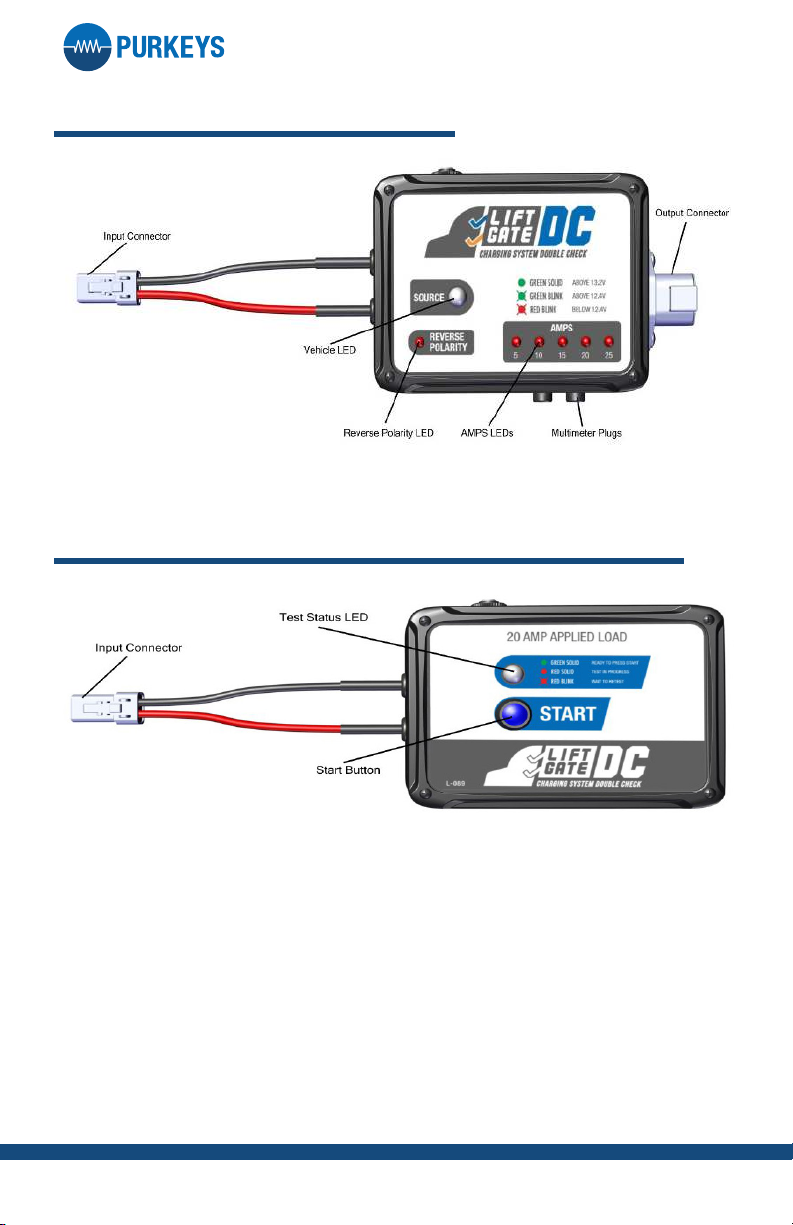

CONNECTING TO THE POWER SOURCE

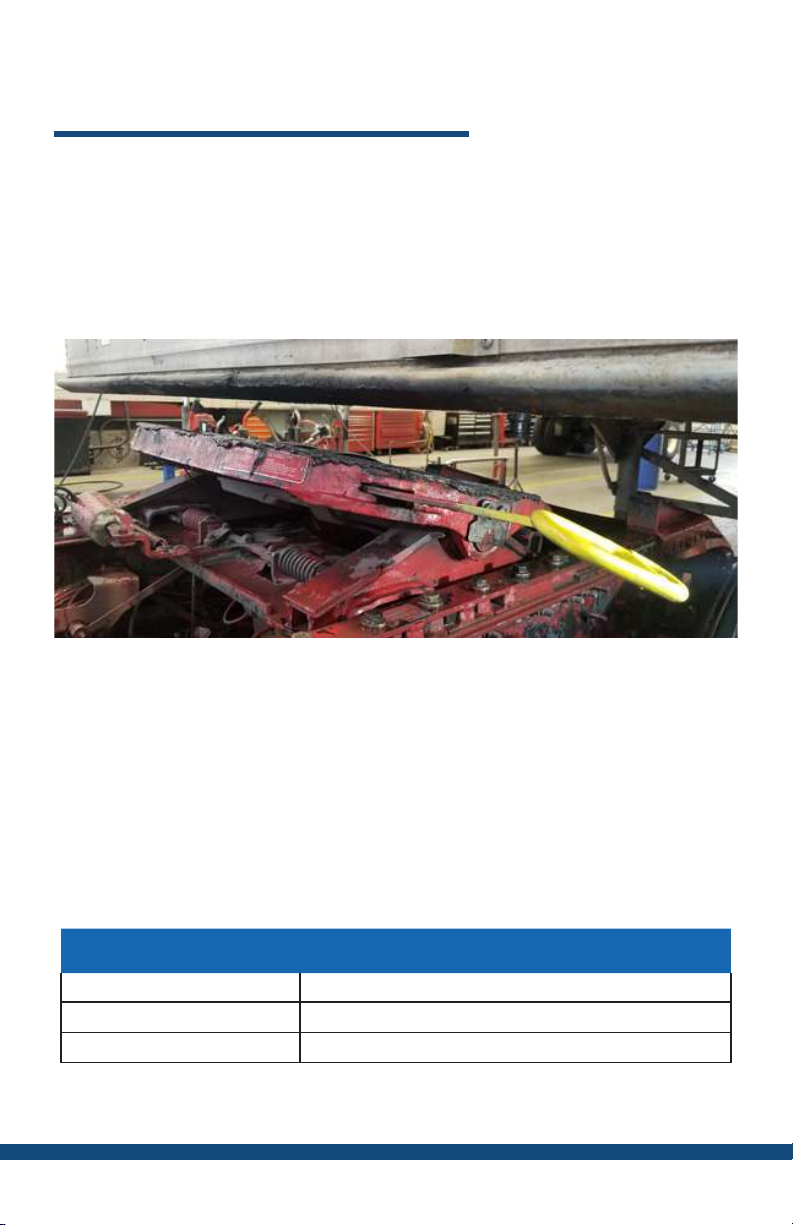

Table 1: 20 Amp Applied Load Tester LED Status

LED STATUS

Solid Green Applied Load is ready to test power source

Solid Red Source is being tested

Blinking Red Applied Load is resetting

e 20 Amp Applied Load Tester is used to test the power source. It is crucial

to test the source while under a load to ensure it can provide the proper

voltage needed. Do not assume the vehicle is an adequate source, as a faulty

source may cause a misdiagnosis of the ligate charging system due to an

inadequate power source.

When using the 20 Amp Applied Load, connect the tool to the Double Check

and the power source and make sure the vehicle is running. e Test Status

LED on the 20 Amp Applied Load Tester will turn on. See Table 1 for LED

indications.