RINS987-2

Changing Inputs

Installing Keypads/Readers

Installing RIXs (Input Expanders)

Installing ROXs (Output Expanders)

Programming Tags Miscellaneous

Changing Outputs The Engineer/Anti-Code Reset

!!

D

C

B

A

Input Name

Input 001

!!

D

C

B

A

Arm Point Arms

[ AB ]

!!

D

C

B

A

Arm Point In

[ A ]

!!

D

C

B

A

Arm Point Name?

!!

D

C

B

A

KEYPAD CODE?

[ ]

!!

D

C

B

A

Input [001]

Input 001

!!

D

C

B

A

Type

Keypad [0]

!!

D

C

B

A

ATE Pin 1[0001]

Fire

In the Engineers Menu, Press m until you reach

‘CHANGE INPUTS’. Press l.

Select the input you would like

to program and press l.

Choose the input type (see

‘input types’ table overleaf)

Select the partition you wish the input to be programmed into.

Enter ‘Any’ or ‘All’ (individual partition or common partition)

‘Input Attributes’ will be displayed. Here you can choose

from several options: Chime, Omittable, Double Knock,

Normally open, Confirm group etc. Press ©to switch

between the different options. Press l for the next option.

‘Input Name’ will be displayed.

Press l,the input name will

be displayed, you may alter this

using the relevant keys for the letters. Once done press l,

and do the same for the rest of the inputs.

Press m to go back to the Engineers menu.

In the Engineers Menu, Press m until you reach

‘ASSIGN KEYPADS/READERS?’. Press l.

Select the address of the keypad/reader you have installed.

Enter the type:

0 = Keypad

1 = Reader

2 = Not Used

(This example shows a keypad) Press l.

‘Arm Point Arms’ will be

displayed, choose which

partitions you would like the

keypad to arm/disarm. Press l.

‘Arm Point Disarms’ will be displayed, choose which

partitions you would like the keypad to arm/disarm. Press l.

‘Arm Point In’ will be

displayed, choose which

partition you would

like the keypad to operate

in. Press l.

‘Arm Point Name’ will be

displayed, if you wish to enter

a name for the arm point

press l.

Press m twice to go back to the Engineers menu.

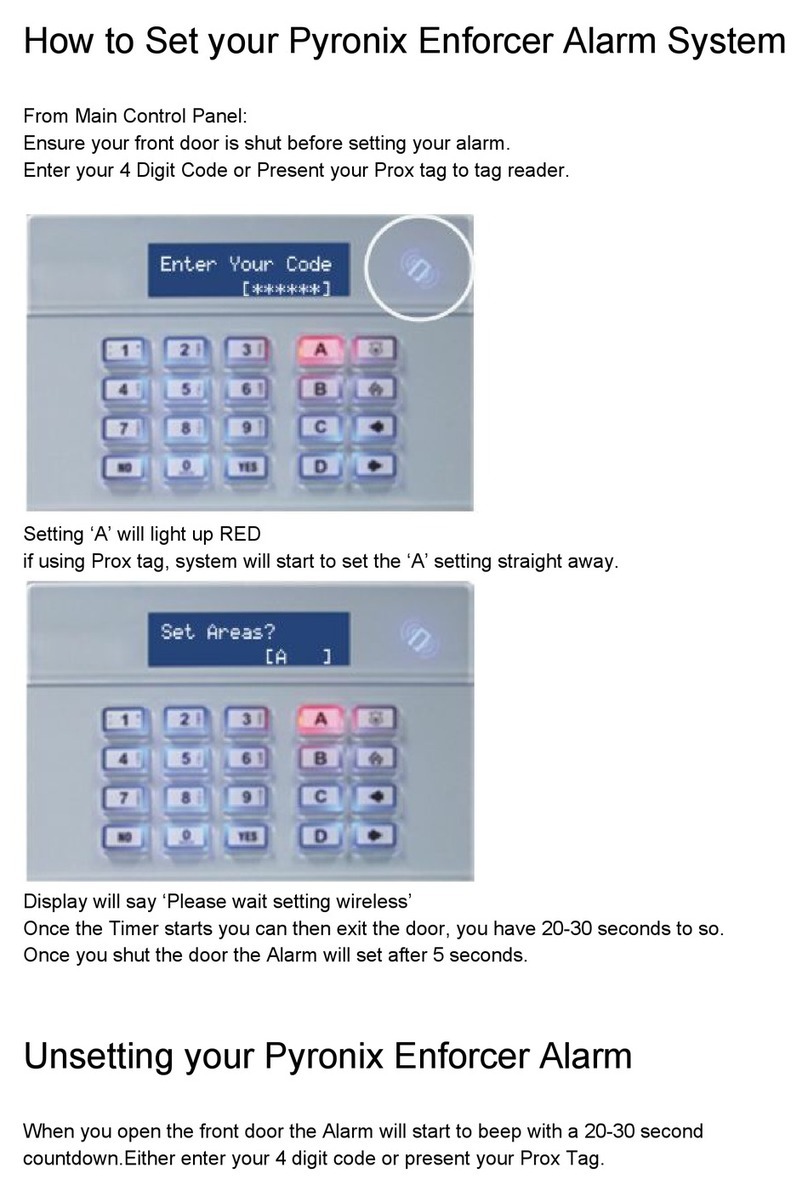

Also you will need to address

each keypad individually.

To do this, in day mode, keep

hold of the © key until

‘KEYPAD CODE’ is displayed.

Release the © key and enter ‘2000’. press l.

‘Address’ will be displayed, enter the relevant address for

the keypad and press l. For other options press l, or

press ¤to save the data.

The Input numbers for each keypad are as follows:

In the Engineers Menu, Press m until you reach

‘CHANGE OUTPUTS’. Press l.

‘Endstation PGMs’ - this allows you to change the onboard

PGMs (PGM1, PGM2, PGM4 or PGM5) and also the ATE

outputs for the communication loom.

Press lEnter the required PGM type (see the table

overleaf) or press © to scroll

through. Press lto go to the

next PGM/ATE number.

Press m once finished.

‘RIX PGMs’ will be displayed, Press lif required and

enter the relevant address of the RIX you wish to program.

Press l and the PGMs may be changed.

Press m once finished.

‘ROX Module PGMs’ will be displayed, here you may

install any PCX-ROXs. Press lif required and enter

the relevant address of the ROX you wish to install.

‘ROX Installed’ will be shown, press © to select ‘YES’ and

Press l - you can now change the relevant PGMs.

Press m once finished.

Do the same for Keypad and Reader PGMs. Press m

once finished, you will be returned to the engineer menu.

In the Engineers Menu, Press m until you reach

‘CHANGE OUTPUTS’. Press l.

Press m until you reach ‘ROX Module PGMs’, here you

may enable any PCX-ROXs you have installed. Press l

‘ROX Address?’ will be displayed, enter the address

of the RIXs you have installed. Press l.

‘ROX Installed?’ will be displayed press © to toggle

between YES and NO. Press l

Press m until you return to the Engineer Menu.

After an alarm activation, a

valid user code may be

entered, this will silence the

alarm. The display will show

‘Alarm Silenced’ on the top line, on the bottom line the

display will show and the activation that has just occurred.

Press l.

The time and date will be displayed and the Power LED will

flash indicating that a restore is required. Enter your

engineering code: “All faults have been cleared” will be

displayed Press l.

After an alarm activation, a

valid user code may be

entered, this will silence the

alarm. The display will show

‘Alarm Silenced’ on the top line, on the bottom line the

display will show the restore number. For Example:

‘Restore G12298’. Press l.

The time and date will be displayed and the Power LED will

flash indicating that a restore is required. Enter the anti-

code reset number, ‘Engineer Restore Performed’ will be

displayed. Press l.

In the Engineers Menu, Press m until you reach ‘INSTALL

RIX?’. Press l.

‘RIX Address?’ will be displayed, enter the address of the

RIX you have installed. Press l.

‘RIX Installed?’ will be displayed press © to toggle

between YES and NO. Press l, you will be returned

to the Engineer Menu.

In day mode, press © and enter the master manager

code (default 5678). Press muntil you reach ‘CHANGE

CODES’. Press l.

‘Change User Codes’ will be displayed. Press l.

Enter the user number you wish the tag to be

programmed on. Press l.

‘Enter User Code’ will be displayed. If there are asterisks

in the brackets then a code has already been entered.

Either delete the code (by pressing §) or press mand

select another user number.

Once the brackets are empty,

hold up a PCX-TAG to LCD

keypad (shown right). The

keypad will be beep if the tag

has been accepted. Press l.

Select the relevant options for the user (to go to the next

option press l). One option that may need to be changed

is ‘Flexi Arm’ - if set to ‘YES’ then you can select which

partitions you would like to arm, or to automatically arm

the partitions when you put a fob up to the keypad set this

option to ‘NO’.

User Level Arm: This function allows the system to

operate as a “Level Arm” (YES) or “Partition” (NO) system.

Common Exit Mode: If set to ‘YES’ this option will

automatically arm the partition on the ‘highest priority’ exit

mode. (Final Exit and PTS are higher than timed exit)

2 Key HU: Keys 1 and 7 pressed together perform a Hold

Up activation. These will need to be enabled in this option.

Flexi-Unset: If set to ‘YES’ you will be required to disarm

each partition manually. Or if set to ‘NO’ the system will

disarm all partitions the code/keypad are assigned to.

Sign On Message: Allows you to add your own company

name on start up (Default PCX 256)

The system can be programmed so that it can be only fully

reset by an engineer or by an anti-code reset. This can be

programmed in “Engineer Reset Options”.

The log stores up to 3000 events. To operate the log

use {and } the and keys to scroll through each event,

to view more information (such as user and input numbers)

press the §key.

By default, all inputs are pre-set as ‘unused’ so you will need to

program each individual input you require. The input will not be

‘live’ until you have exited the engineers menu.

The keypad has an inbuilt tag reader and can be used to

arm/disarm the system without entering a user code.

To program tags into the system you must be in the master

manager menu (NOT the Engineers menu).

Other notable Engineer functions::

This function allows you to enable any keypads or proximity

readers you have installed on the system. You must exit

the Engineers menu in order for the changes to take affect.

241-242

243-244

245-246

247-248

249-250

251-252

253-254

255-256

Input Number

LCD Keypad 00

LCD Keypad 01

LCD Keypad 02

LCD Keypad 03

LCD Keypad 04

LCD Keypad 05

LCD Keypad 06

LCD Keypad 07

Address

!!

D

C

B

A

Enter User Code

[******]

Tag

,/+.

JKL

ABC

MNO

DEF

PQRS

GHI

TUV

WXYZ SPACE

Site Options

Performing an Engineer Reset

Performing an Anti Code Reset

System Displays

Engineer Reset Options

Review Logs

This function allows you to enable Engineer Reset for

different alarm types such as Intruder, Hold Up, Confirmed

etc. Also allows you to enable an Anti-Code reset.

!!

D

C

B

A

Alarm Silenced

Restore Required

!!

D

C

B

A

Alarm Silenced

Restore G12298