4

8OXYGEN CALIBRATION STANDARDS ....................................68

8.1 THE AIR CALIBRATION STANDARD ..............................................68

8.1.1 Ambient Air ....................................................................... 70

8.1.2 Water-Vapor Saturated Air .................................................71

8.1.3 Air Saturated Water............................................................71

8.2 THE 0% OXYGEN STANDARD..................................................... 72

8.2.1 Water Mixed with a Strong Reductant ................................ 72

8.2.2 Water Flushed with Nitrogen Gas........................................73

8.2.3 Nitrogen Gas ......................................................................73

9CALIBRATION OF CONTACTLESS SENSORS ..........................74

9.1 CALIBRATION PROCEDURE......................................................... 74

9.2 MANUAL BACKGROUND COMPENSATION .................................... 75

10 TEMPERATURE MEASUREMENT............................................ 77

10.1 EXTERNAL (PT100) TEMPERATURE SENSORS................................77

10.2 INTERNAL TEMPERATURE SENSOR ...............................................77

10.3 OPTICAL TEMPERATURE SENSORS .............................................. 78

10.4 AUTOMATIC TEMPERATURE COMPENSATION................................ 78

11 ANALOG OUTPUT AND AUTO-MODE ....................................81

11.1 ANALOG OUTPUT .................................................................... 81

11.2 AUTO-MODE...........................................................................84

11.3 ADVANCED AUTO-MODE ..........................................................86

12 APPENDIX............................................................................ 88

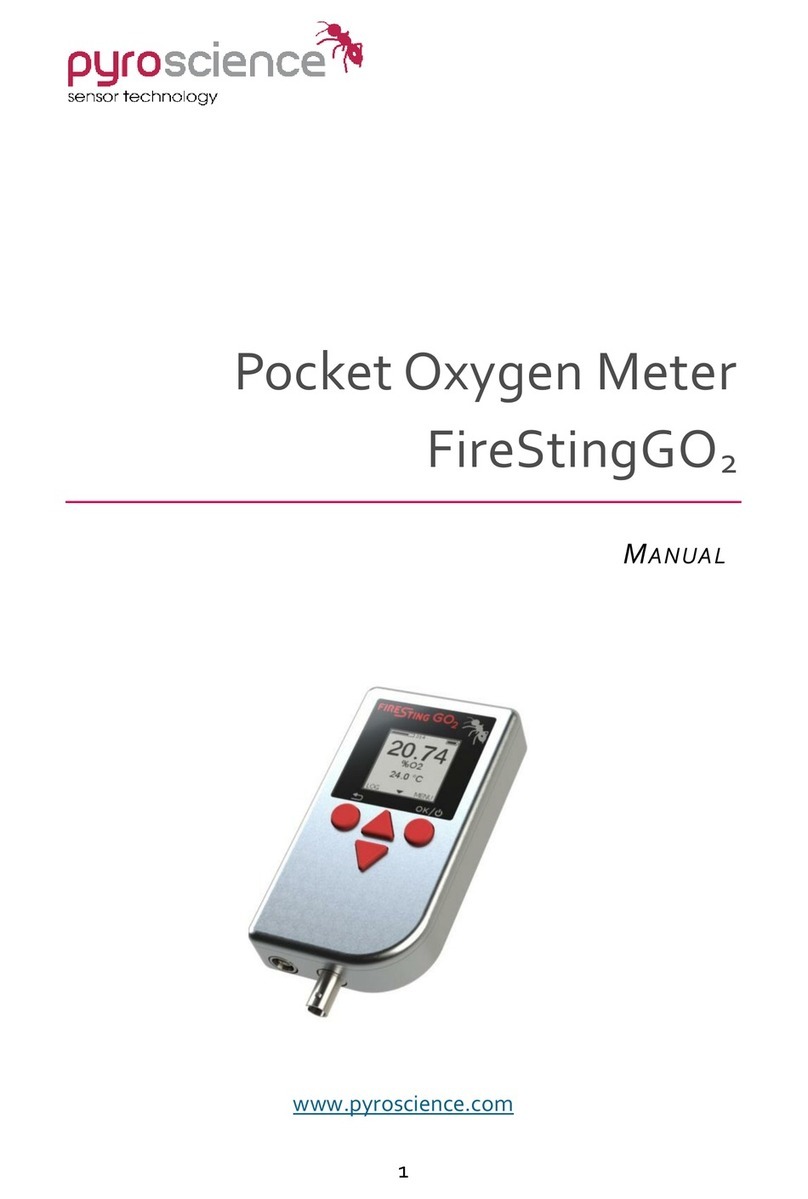

12.1 SPECIFICATIONS OF THE FIRESTINGO2.........................................88

12.2 EXTENSION PORT X1 ................................................................90

12.2.1 Connector X1 (Power, Digital Interface, Analog In).......... 90

12.2.2 Connector X2 (Analog Output) ....................................... 95

12.3 TROUBLESHOOTING .................................................................96

12.4 OXYGEN MEASURING PRINCIPLE ................................................ 97

12.5 OPERATING SEVERAL FIRESTINGO2 IN PARALLEL...........................99

12.6 DEFINITION OF OXYGEN UNITS................................................. 100

12.7 TABLE OF OXYGEN SOLUBILITY ................................................ 102

12.8 EXPLANATION OF THE SENSOR CODE ........................................ 104