06 07

Tel: +44 (0) 1253 789180 Tel: +44 (0) 1253 789180

POWER MAX 560 Tile Cutter

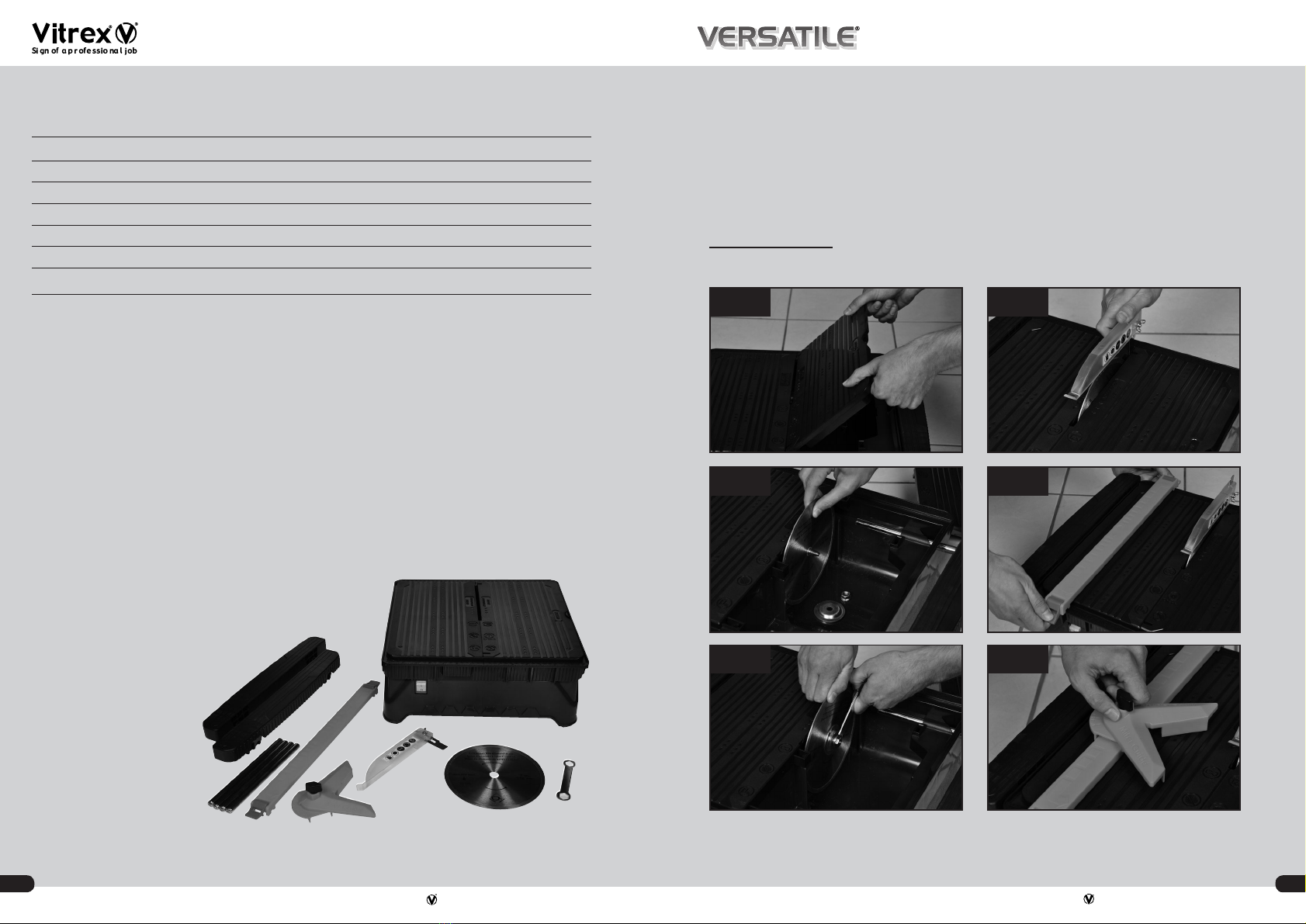

FIG.G

FIG.H

FIG.I

FIG.J

Maintenace

• Always check the blade before use for

cracks or signs of damage.

• Ensure that the reservoir is lled up to the

recommended level. Do not overll or

allow it to run dry.

• Always clean the machine after use, after

rst ensuring that it is disconnected from the

mains.

• Rinse out reservoir thoroughly to remove

all sludge and wipe down outside of

machine using a cloth or sponge.

• When not in use, store the electrical cable

and plug under the machine in the space

provided.

• No other servicing is required in normal

use. No attempt should be made to repair

or replace internal components as this will

invalidate any claim whilst the product is

under guarantee. Q.E.P. Co UK Ltd is committed to a continuing program of

product improvement. Consequently, please be advised

that specications, performance, appearance, and

dimensions of QEP/Vitrex products are subject to change

without notice. For more up-to-date information about our

range of products, please contact our Customer Service

Ofce on +44 (0)1253 789180 or your local distributor.

Consumer Advice

• Do not dispose of electrical products

with your normal householdwaste.

• Always use recycling facilities

whenever possible.

• Additional recycling information can

be found through your local Authority

or Retailer.

• For further information or advice, please

call the Vitrex Technical Helpline on

+44 (0) 1253789180.

Dual Extension Outriggers

To assemble the outriggers, screw the steel

bars into the extension platforms and using

the screws provided to secure them. Once

assembled, slot into the base of the tile

cutter in the relevant holes.

Tile Cutter Operation

Take out the electrical cord to connect to the

power source. The electrical cord is stored

underneath the counter.

Detach the splash guard, and then open the

right cutting table to ll the reservoir with

water to the recommended level.

Attention! Keep water level within lines. (See

Fig G)

Attach the splash guard above the blade and

close to the right cutting table.

Now you are ready to cut!

Steps for rip, angle and mitre cuts :

The edge of the cutting table (upper frame) is

marked with rigid dimension in both inches

and centimetres for accurate cutting.

For 90˚ rip cuts

After the rip guide is positioned for the

desired dimension, lean the material against

the rip guide then push the material forward

to the blade. (See Fig H)

For 0˚ – 45˚ angle cuts

Attach the mitre guide on the rip guide.

Choose the degree you want and tighten the

adjustment knob. Then push the mitre guide

and material together forwards for the

blade to cut the material.

(See Fig I)

For mitre cuts

Raise the right cutting table at the desired

angle, you can choose 22.5˚, 30˚ and 45˚.

Put the two stands into the grooves to hold

the cutting table in place. Place the material

face down onto the left cutting table and you

are ready to cut. (See Fig J)

This electric tile cutter has been manufactured to a high quality standard. It is guaranteed against faulty materials and

workmanship for 12months from the date of purchase. Any claim must be accompanied by a valid till receipt as proof of purchase.

A faulty machine will either be repaired or replaced free of charge. If a direct replacement is not available, an alternative to the

same or greater value/specication will be offered.

This guarantee does not cover machine defects caused by or resulting from:

a) Misuse, abuse or neglect, b) Trade, Professional or hire use, c) Repairs attempted by anyone other than our authorised repair

agent, d) Ingress of foreign objects, substances or accident

In the unlikely event of a fault occurring, contact should be made through the Vitrex Technical Helpline +44 (0) 1253 789180

The above guarantee is only valid within the UK and does not affect your statutory rights.

The guarantor is Q.E.P. Co. UK Ltd., Everest Road, Lytham St. Annes, Lancashire, FY8 3AZ (Registered No. 04988177 England).