02 03

Tel: +44 (0) 1253 789180 Tel: +44 (0) 1253 789180

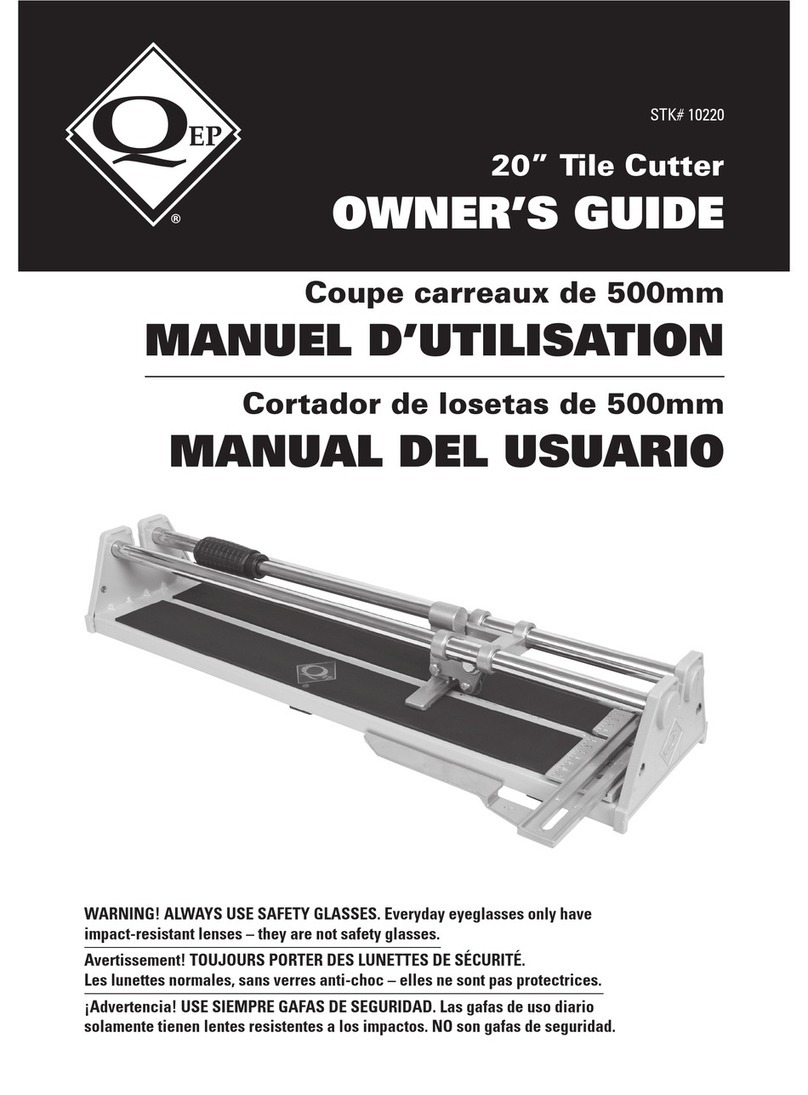

OwnerÕs Safety and Operating Manual

Contents

Safety Instructions ..................................................3

Machine Specication & Electrical Requirements .....4

Assembly & Operating Instructions ......................5-6

Maintenance & Warranty ........................................7

Safety Instructions

When using the machine, always observe

the enclosed safety instructions as well as

the additional safety instructions.

Denotes risk of personal injury or damage

to the tool.

Take measures to protect your eyes.

Take measures to protect hearing.

Do not use toothed cutting discs.

Consult the manual.

Additional Safety Instructions

for Tile Cutters

• Make sure that the cutting disc is

correctly screened by the guard.

• Do not use cutting discs which are bent,

deformed or otherwise damaged.

• Do not use cutting discs which do not

comply with the specications stated in

this manual.

• Never start cutting tiles before the

machine reaches full speed.

•Never attempt to cut extremely small

workpieces.

•Do not leave the work area until the

machine has been switched off and the

cutting disc has come to a complete

stand-still.

• Never attempt to stop the cutting disc by

exerting pressure on the side of the disc.

• Before use check the pump for damage.

Should the pump be damaged, it must

not be used.

• Never let the pump run dry.

• Never lift the pump by the mains cable or

hose, but only by the housing.

• Always unplug the machine before

performing any maintenance.

• Do not use the machine before it has

been completely assembled and

installed according to the instructions.

• Do not perform any design, assembly or

construction activities on the table while

the machine is switched on.

• Unplug the machine and clean the table

before leaving the work area.

Electrical Safety

Always check that the power supply corre-

sponds to the voltage on the rating plate.

Conditions of the

Tile Cutter (FIG.A, FIG.B)

The tile cutter can work in conditions of FIG.A

and FIG.B either on the stand provided or

placed in a work area.

Description (FIG. C)

Your tile cutter has been designed for cutting

ceramic and clay paving and wall tiles.

1 - Leg1

2 - Leg2

3 - Brace

4 - Small work table

5 - Water pump

6 - On/off switch

7 - Motor

8 - Ruler

9 - Big work table

10 - Cooling water reservoir

11 - PRCD plug

Mounting the Frame (FIG. D)

• Hold the brace (3) in place at one side.

• Mount the rst Leg2 (2) into the hole of

brace (3)

• Mount the others according to the same in-

structions to the brace (3).

• Mount the rst long Leg1 (1) into the hole of

Leg2 (2)

• Mount the others according to the same in-

structions to the Leg2 (2).

Power Pro 600 Tile Cutter

Power Pro 600 Tile Cutter