Rev-1115-12

© 2018 Q-Tran Inc. All rights reserved | 155 Hill St. Milford, CT 06460 | 203-367-8777 | [email protected] | www.q-tran.com | Specification subject to change | REQUIRED HARDWARE: per 12” installation

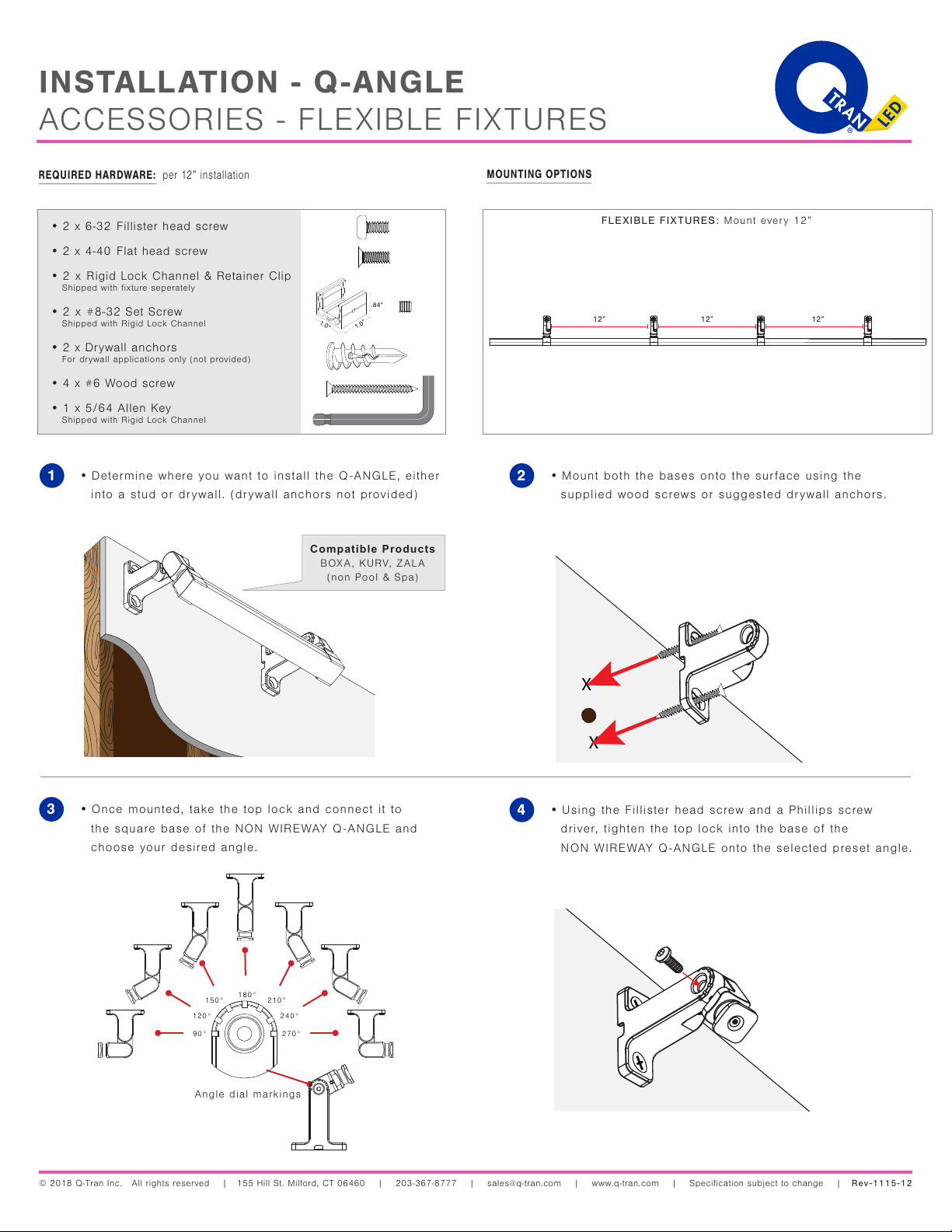

•2 x 6-32 Fillister head screw

•2 x 4-40 Flat head screw

•2 x Rigid Lock Channel & Retainer Clip

Shipped with fixture seperately

•2 x #8-32 Set Screw

Shipped with Rigid Lock Channel

•2 x Drywall anchors

For drywall applications only (not provided)

•4 x #6 Wood screw

•1 x 5/64 Allen Key

Shipped with Rigid Lock Channel

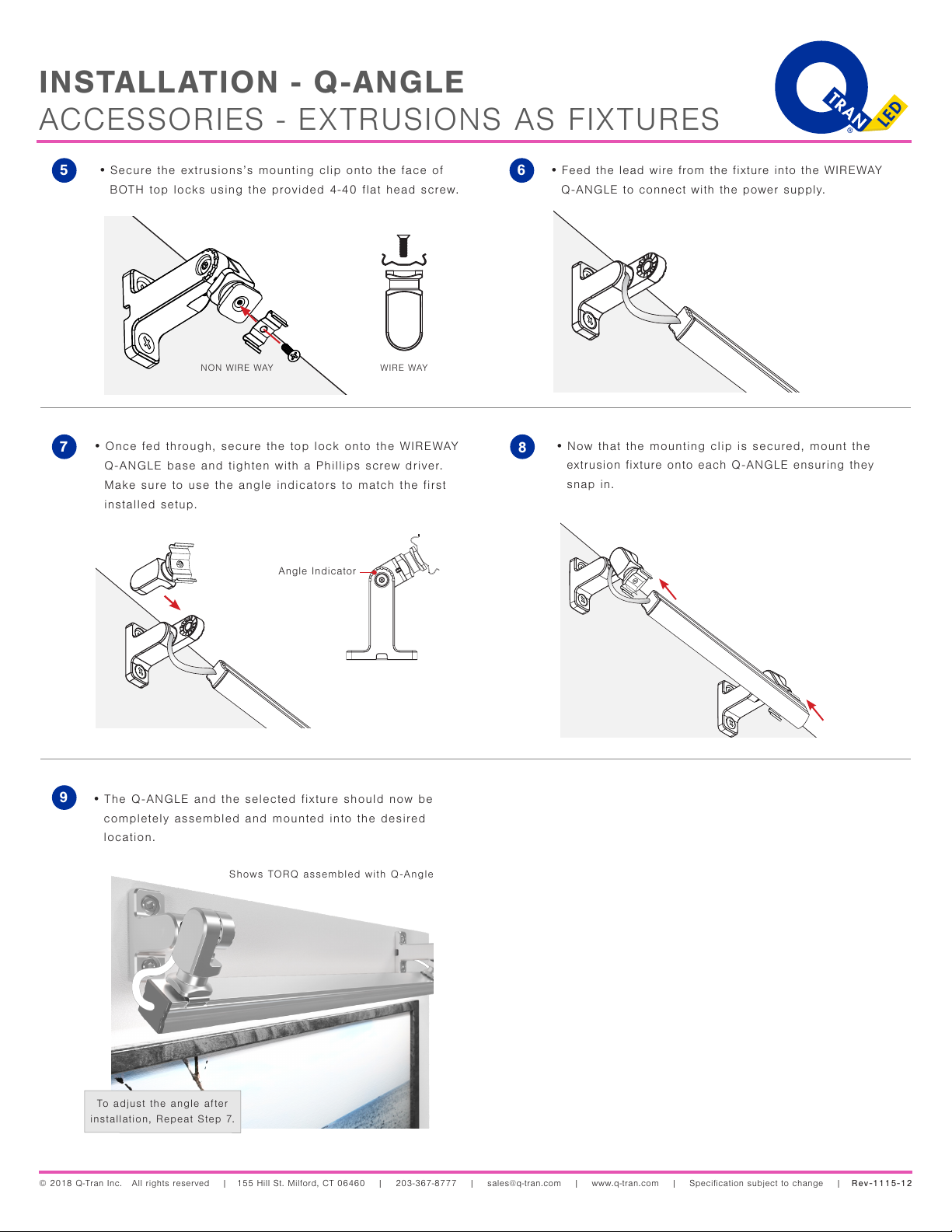

•Once mounted, take the top lock and connect it to

the square base of the NON WIREWAY Q-ANGLE and

choose your desired angle.

3

MOUNTING OPTIONS

•Mount both the bases onto the surface using the

supplied wood screws or suggested drywall anchors.

2

X

X

90° 270°

240°

210°

180°

150°

120°

•Determine where you want to install the Q-ANGLE, either

into a stud or drywall. (drywall anchors not provided)

1

Compatible Products

BOXA, KURV, ZALA

(non Pool & Spa)

Angle dial markings

INSTALLATION - Q-ANGLE

ACCESSORIES - FLEXIBLE FIXTURES

1.0”

FLEXIBLE FIXTURES: Mount every 12”

•Using the Fillister head screw and a Phillips screw

driver, tighten the top lock into the base of the

NON WIREWAY Q-ANGLE onto the selected preset angle.

4