9

GP-1200 6-IN-1 SEEDER INSTRUCTION MANUAL

3

PLEASE READ OPERATING INSTRUCTION CAREFULLY BEFORE USE.

› Do not turn right when the plow discs are in the ground or damage to the disks

will occur. Left turns ONLY when discs are engaged.

› Do not sit, stand or ride on the seeder while in use.

› Maximum capacity of the seeder box seeder 1200 is 25kg per box

› Do not put hands in seed box while seeder motor is in the on position.

› Do not put lime in seeder.

› Only use granulated fertiliser.

› Keep hands and feet clear when raising and lowering unit.

› Keep hands and ngers clear when raising or lowering the drag and/or press roll

to avoid pinching.

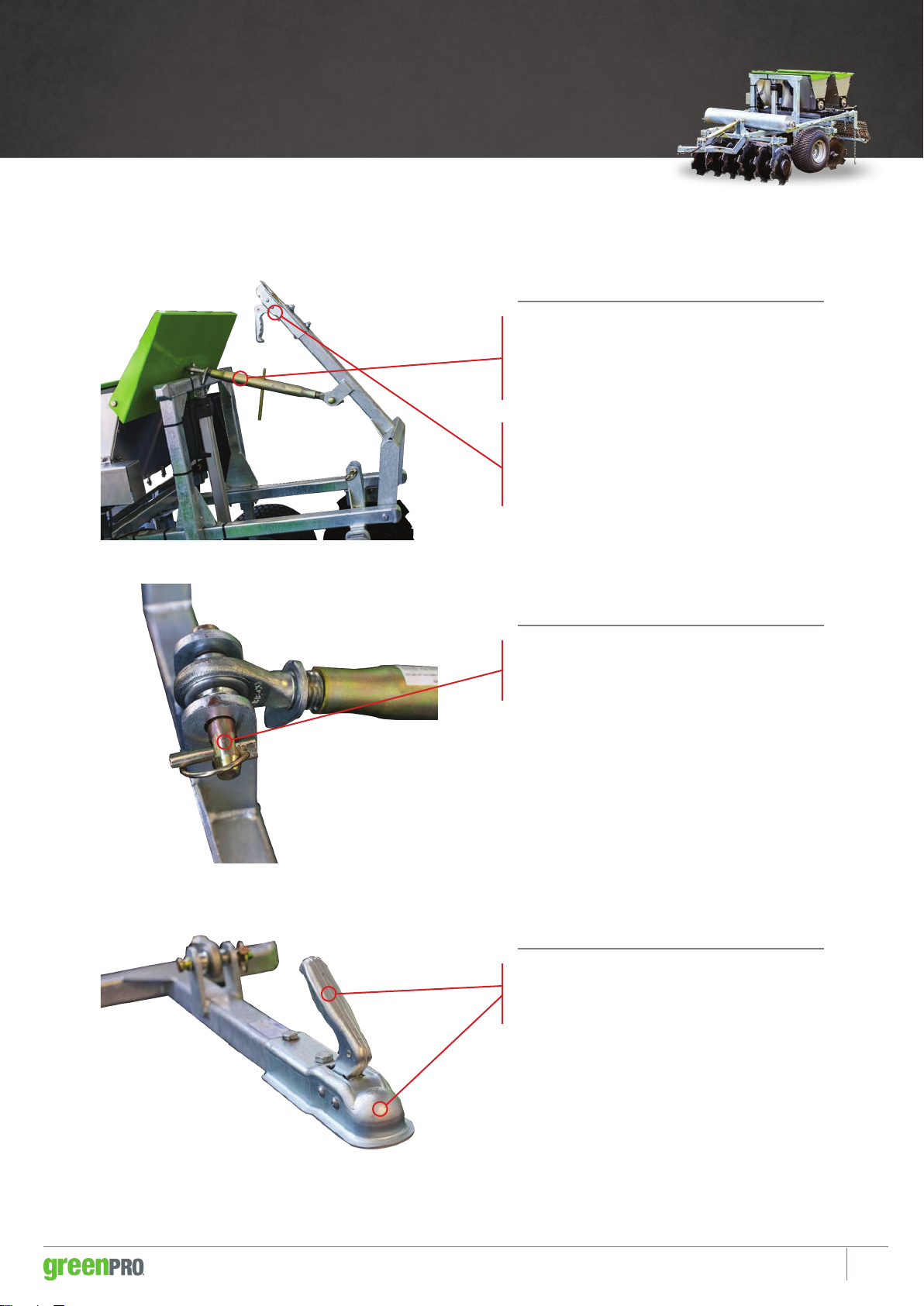

› The seeder 1 point hitch units, can be used with ATVs/UTVs & with tractor’s

that have draw bar/single point connections.

› Seeder is designed for off road use. DO NOT tow on public roadways.

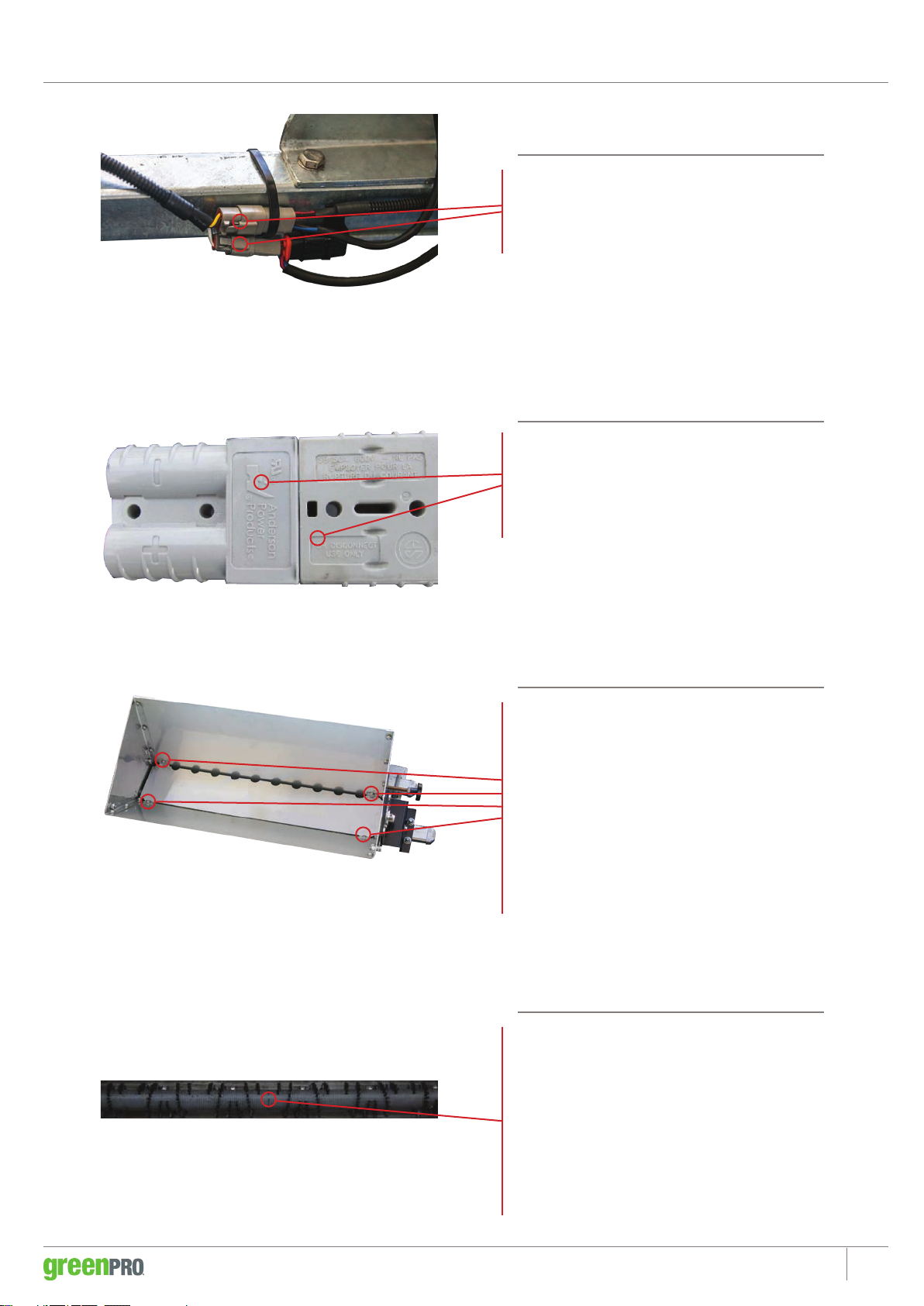

› Make sure that the battery clips are connected to the proper terminals to avoid

damage to your electrical system and/or your ATV/UTV/tractor.

(Red = positive terminal. Black = negative terminal)

› Avoid coming in contact with any other metal parts on the ATV when

connecting the battery clips to your battery.

› Adding lime or non-granular fertiliser to your seeder will void the warranty of

“all” parts associated with the seeding system.

› In addition the density of Lime is much greater than seed and can bind your

brush shaft causing the motor to “burn out”.

› Seed is far lighter and will not compact around your Seeder Brush and cause

damage to your seed motor like lime/non-granular fertiliser can.

DO NOT OPERATE YOUR SEEDER ON INCLINES

GREATER THAN 10°.

WARNING

BASIC OPERATIONAL

INFORMATION