1.4 FUNCTIONAL DESCRIPTION

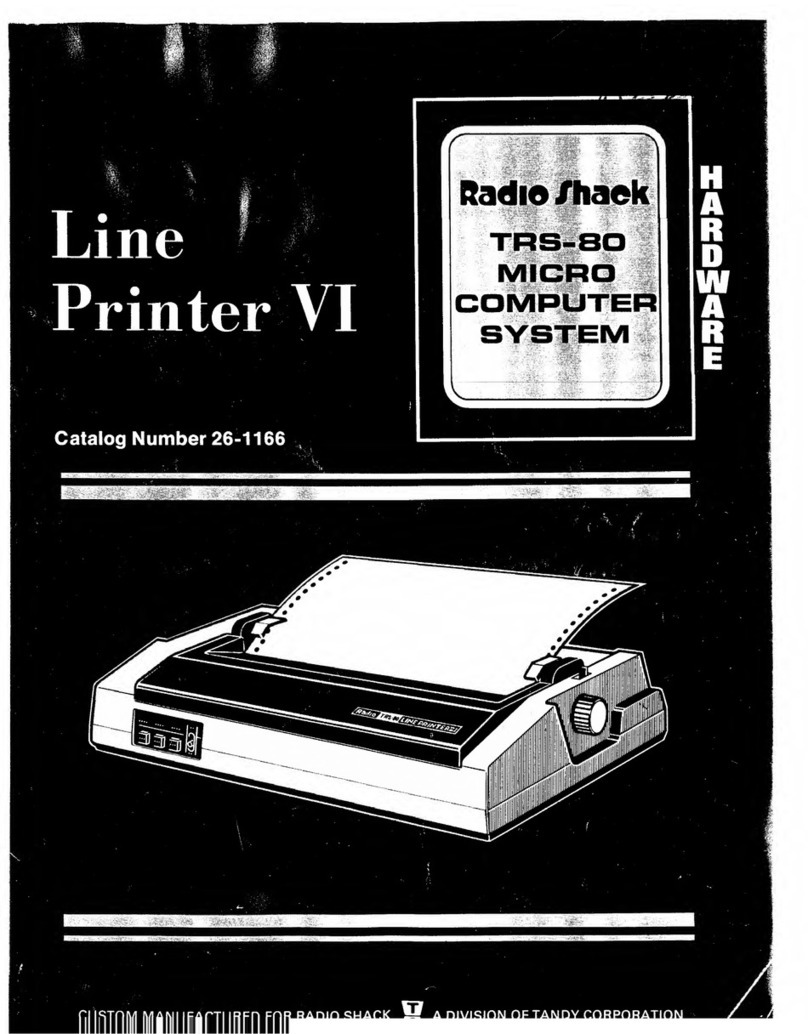

Figure 1-2 is apictorial diagram of the Line Printer II. All of

the logic, control, and power supply circuits are contained on the logic pcb

(printed circuit board) .The printer employs amicroprocessor located on the

logic pcb to control printer operation. Under program control the micro-

processor controls the receiving of input data from the host device, monitors

printer status, initiates and controls movement of the carriage assembly,

controls printing by the print head, and controls paper movement. It monitors

the position of the print head at all times and provides printer status

information to the host device.

The host device transmits 8-bit parallel (ASCII) data and adata

strobe signal to the printer logic pcb. Control of the transmission of data

between the host device and the printer accomplished using the acknowledge

(ACK) ,BUSY, and DEMAND signals. Data transmitted by the host device is

strobed into the logic pcb circuits by the DATA STROBE signal. The printer

responds by sending aBUSY signal to host device indicating printer is opera-

ting on the data. After processing the data the printer sends an acknowledge

signal to the host and the BUSY signal is discontinued. The DEMAND signal is

the inverse of the BUSY signal and when present indicates to the host that the

printer is not busy and can accept data.

The input data applied to the printer consists of character data and

control code data. Character data is stored in an input buffer until the data

is to be printed. Control codes are interpreted as instructions by the

printer and provide the means for host control of the printer.

Input character data is stored in the input buffer until the buffer

is full, or until acarriage return (CR) control code is received. ACR

control code is interpreted as aprint command by the printer. Receipt of a

CR control code by the printer intitiates printing of the contents of the

input buffer. Printing is also initiated when the input buffer becomes

full. In the 10 cpi mode buffer full is 80 characters while in the 16.7 cpi

mode buffer full is 132 characters.

Characters are printed by selectively energizing the print head

solenoids which in turn activate the pins of the print head which are arranged

in acolumn. As the print head is moved across the paper the appropriate pins

are activated driving them against the ribbon paper, and platen to form

characters in a7x7 dot matrix.

The print head is mounted on the carriage assembly. Printing occurs

only when the carriage is moved from left to right. When the printer is

turned on and after printing each line, the print head is moved to the left

side of the printer mechanism. The carriage assembly is driven by areversible

dc motor mounted on the assembly. When aprint command (CR) is received the

motor is energized, the carriage assembly is moved in the forward direction,

and the contents of the input buffer is printed. As the carriage assembly

moves, an encoder wheel (which has magnets imbedded in it) is rotated. The

column sensor (Hall effect device) senses when each of the magnets moves past

it and generates column sense signals which are used to synchronize the

print head solenoids. Upon completion of printing aline of data, the polarity

of the dc voltage applied to the carriage drive motor is reversed and the

carriage assembly is moved to the left side of the printer.

1-4