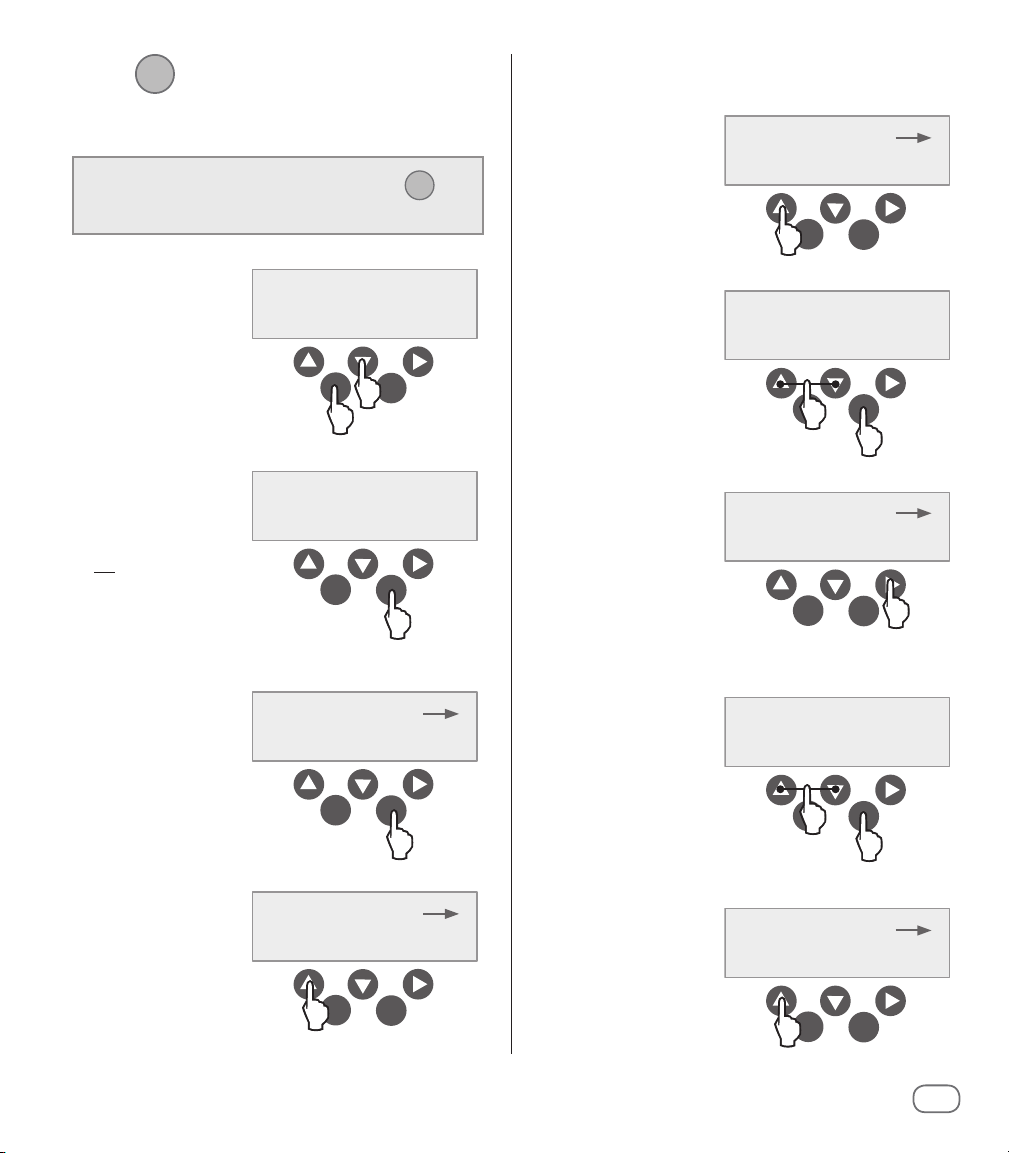

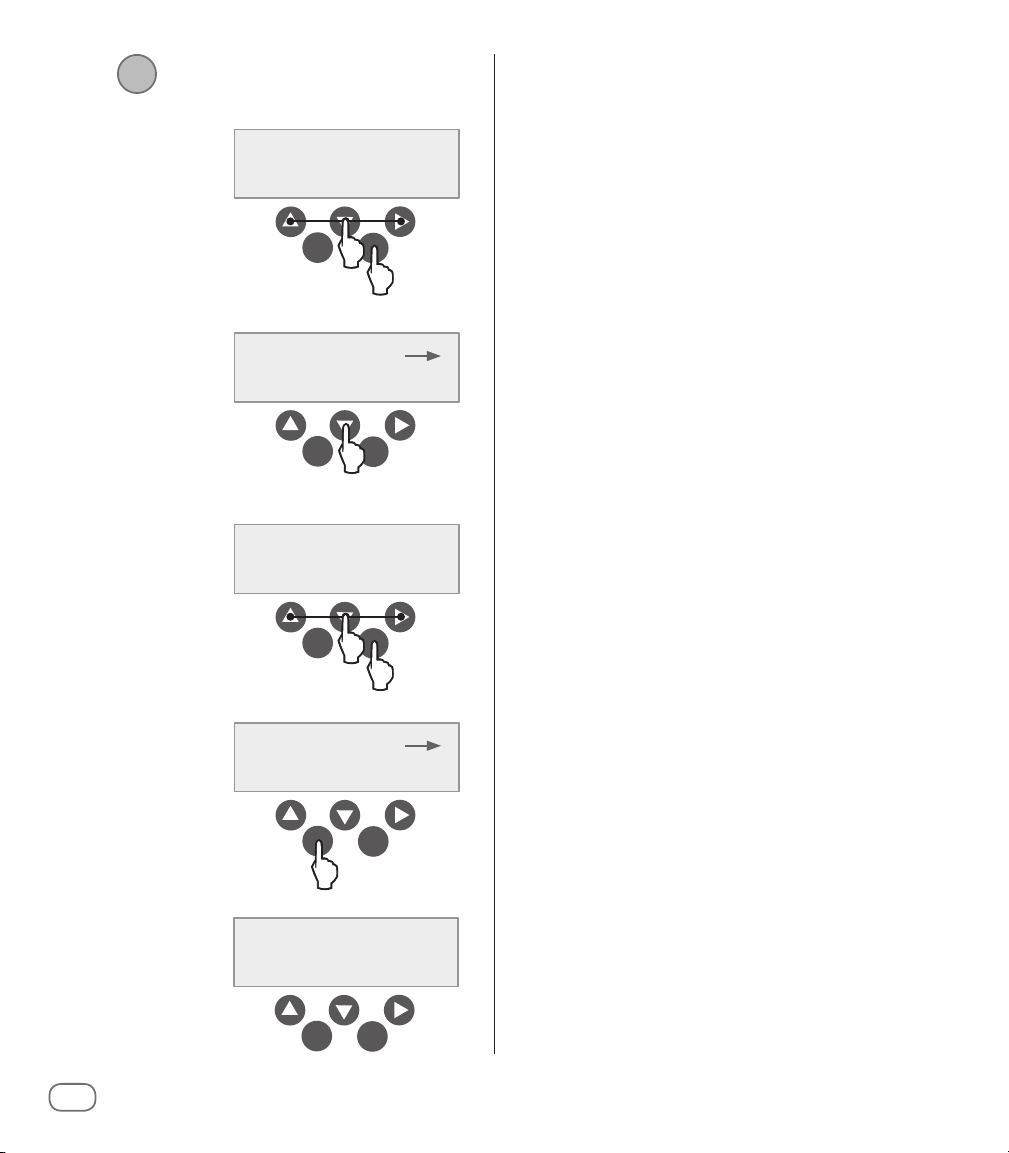

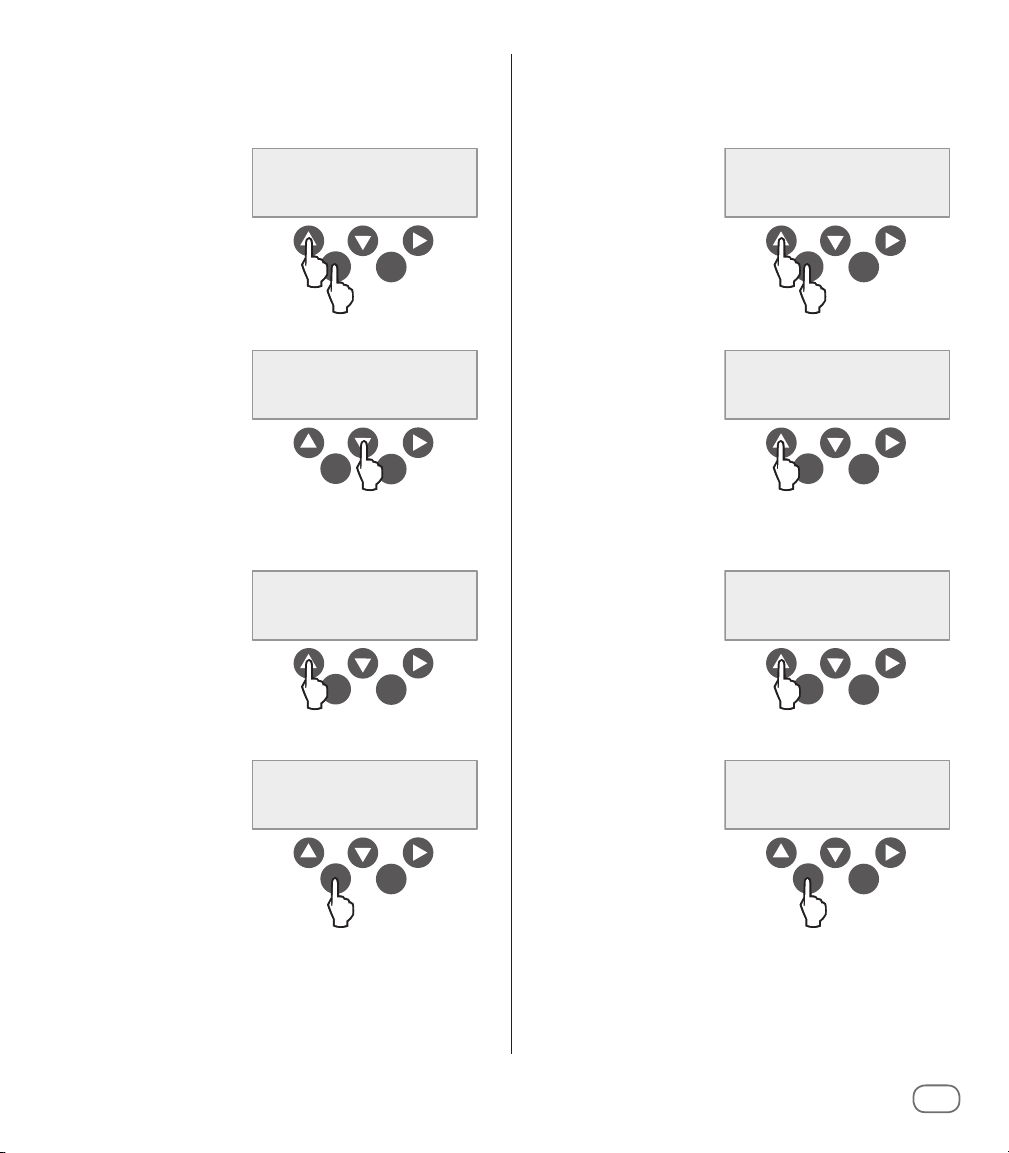

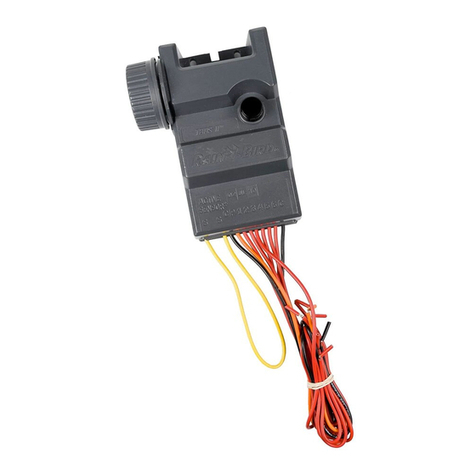

Rain Bird PT3002 Technical specifications

Other manuals for PT3002

1

Table of contents

Languages:

Other Rain Bird Transmitter manuals

Rain Bird

Rain Bird TBOS SYSTEM 6LR61 User manual

Rain Bird

Rain Bird TBOS-II User manual

Rain Bird

Rain Bird RMX-1T User manual

Rain Bird

Rain Bird TBOS-II User manual

Rain Bird

Rain Bird TBOS-II User manual

Rain Bird

Rain Bird TBOS 635098 User manual

Rain Bird

Rain Bird TBOS-II User manual

Rain Bird

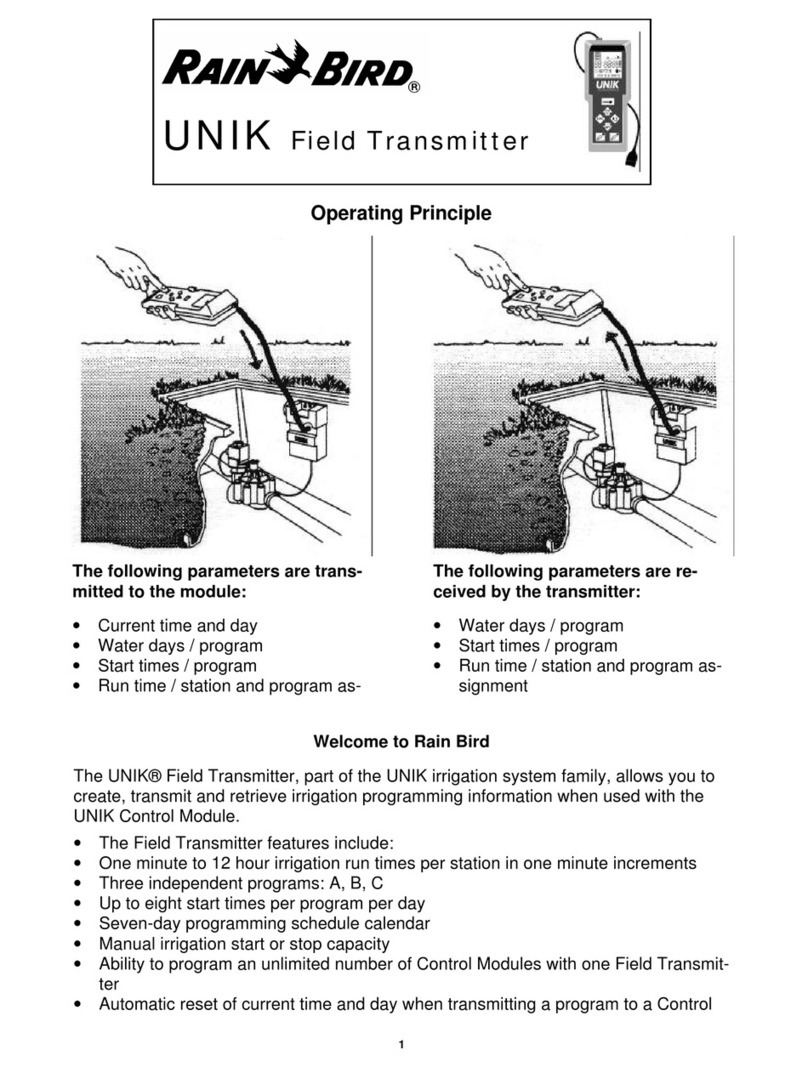

Rain Bird UNIK Field Transmitter Instruction sheet

Rain Bird

Rain Bird CYCLIK Micro Operating instructions

Rain Bird

Rain Bird TBOS User manual

Popular Transmitter manuals by other brands

ABB

ABB TTF350 Commissioning instructions

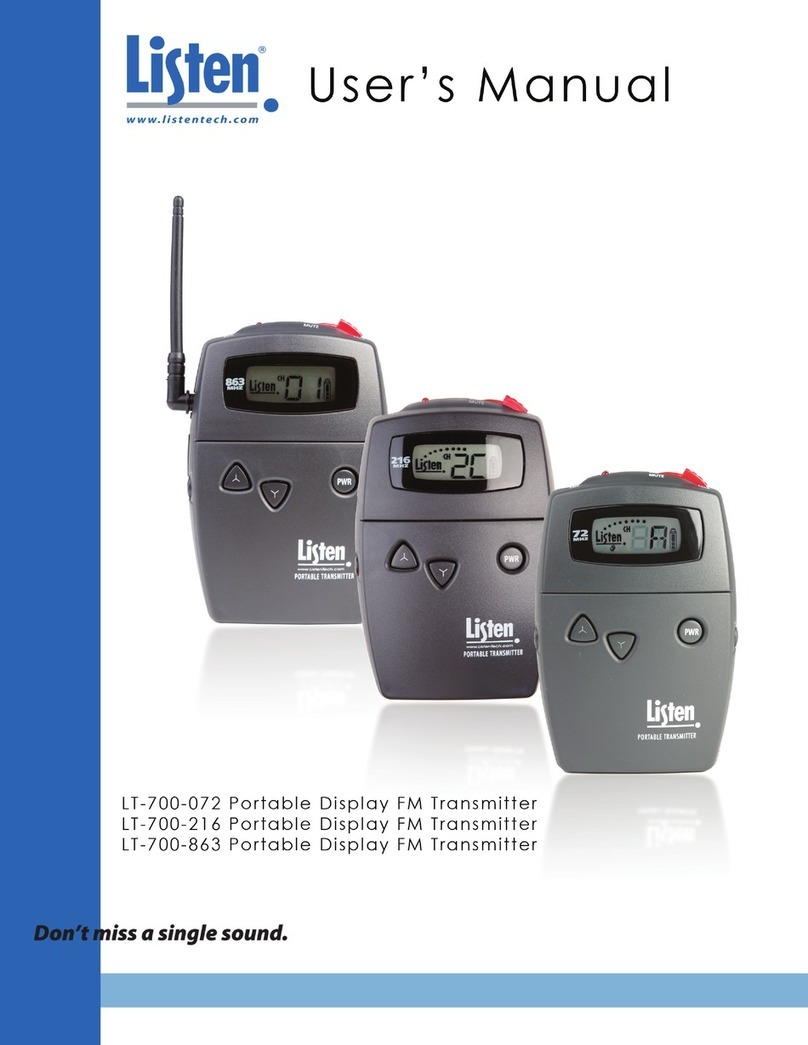

Listen

Listen LT-700-072 user manual

Align

Align A10 INSTALLATION AND INSTRUCTION

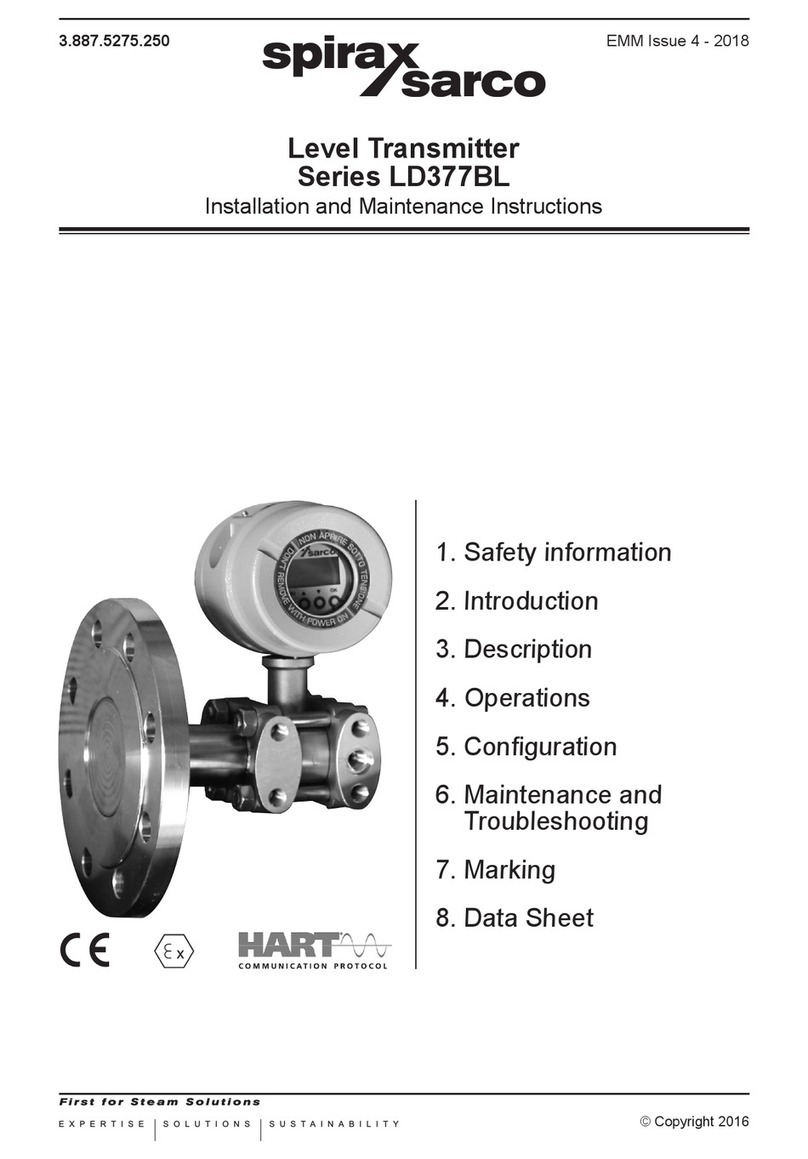

Spirax Sarco

Spirax Sarco LD377BL Series Installation and maintenance instructions

Williams Sound

Williams Sound Personal PA PPA T36 Specifications

Rosemount

Rosemount 2051 Quick installation guide