12. REPLACEMENTOFTHEMOTOR BRUSHES

8

13. BLADESHARPENING

1

9

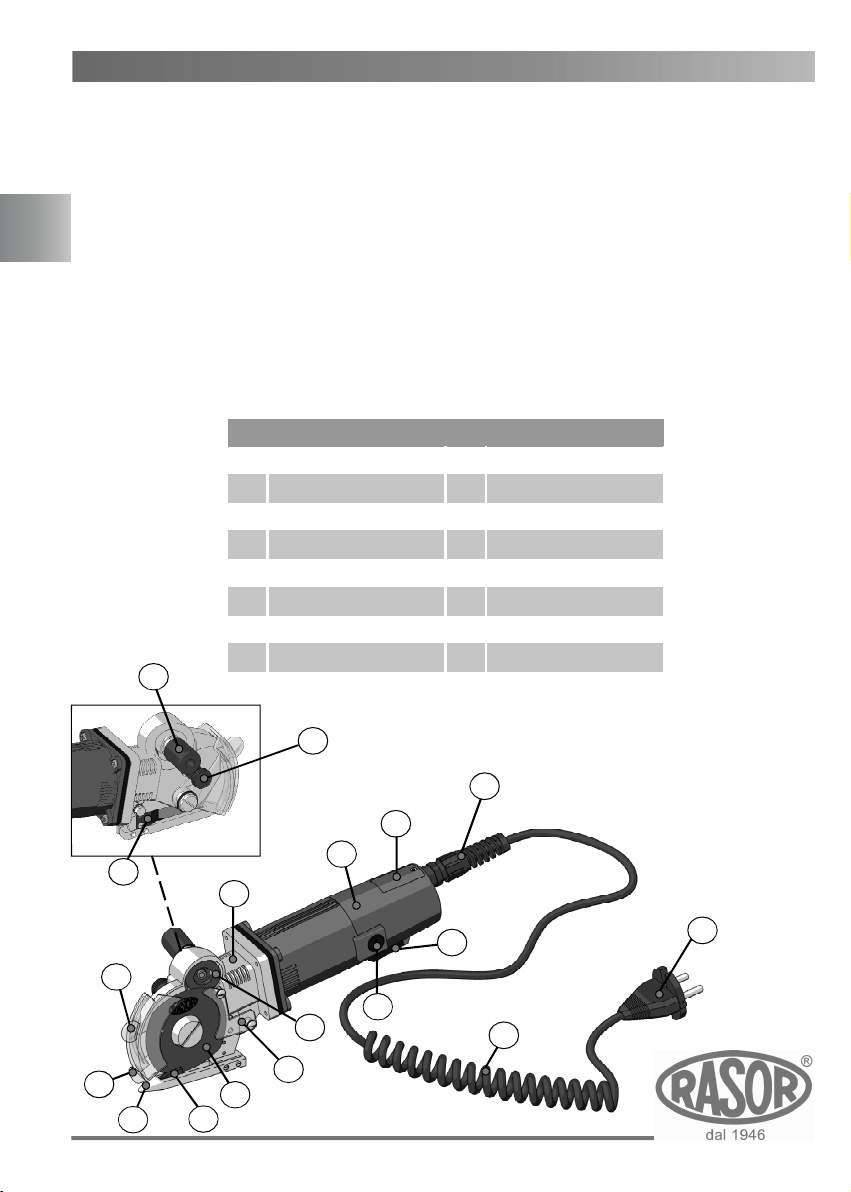

14. LUBRICATION

Every3-4daysof use,itisnecessaryto lubricatethepair

of gears.Tocarryoutthisoperation,removeprotective

plug“A”locatedontheheadof theelectricscissorsand

fill itwith thesuppliedlubricatinggrease.Screwplug“A”

againfewturns.Screwplug“A”someturns every2-3

workinghours(see picture10).Fill theplugagain,once

ithasbeentightened.

Theblademust neverbedirtywithgreaseoroil.

10

WARNING

A

2

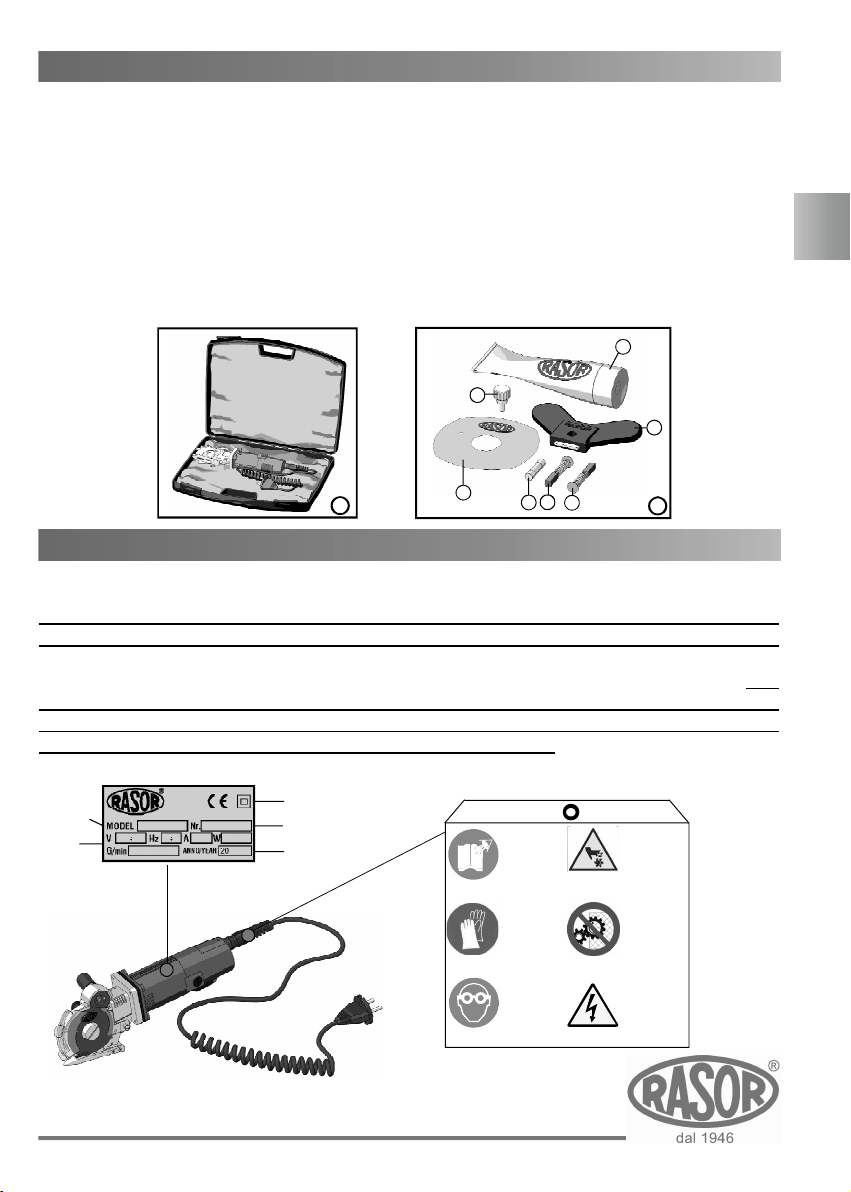

ElectricscissorsOPTIMA 702 areprovidedwithahighpower

permanentmagnetmotorandtorque.Forthisreasonitisnecessary

tocheckperiodicallyifthecarbonbrushesareworninordernot

tojeopardizethemotoroperationanditsdurationperiod.Unscrew

thecapslocatedonthecoverbymeans ofaslottedscrewdriver

(seepicture8);withdrawthecarbonbrushes,checkiftheyare

wornand,ifneeded,replacethem.Assemblethetwocapsagain,

beingcarefultoholdtheminaperfectlyverticalposition,and

screwthemcompletelyonlywhenyouaresurethatthemouthisthecorrectone.

Note: Thebrush must beinsertedwithits black partdirectedinsidethemotor.

Note: Aslightdifferenceinthewearof thetwobrushesisabsolutelynormalinapermanent

magnetmotor.Nevertheless,intheeventthatthedifferencebetweenthemisexcessive,

itisnecessaryto applyto atechnicalcenterforacompletecheck of thefixture.

Beforecarryingoutanyoperations ontheelectricscissors,makesurethatthesupplyplug

isnot connectedto themains.

WARNING

Aftermanyhoursof acontinuativeuseof theelectricscissors

oriftheyarenot abletocutanymore,itisnecessaryto

sharptheblade.Tocarryoutthisoperation,starttheblade

andpress sharpeningbutton“1”for3-4seconds(asshown

inpicture9).Repeatthisoperation2-3times.

Ifthesharpeningprocess shouldbeineffective,check the

wearoftheemerygrindingwheel“2”(seepicture9).If

wheel“2”istoo wornordirty,replaceitbyremovingthe

bladewiththepropertool.

WARNING

Thesharpeningbuttoncanbeonlypressedifthefrontmobileprotectioniscompletely

lowered.

Enfocus Software - Customer Support

EN

26