Raychem pyrotenax Alloy 825 User manual

MI Cable Industrial

Wiring Installation Manual

For Alloy 825 Sheath Cables

Important Safeguards

nVent RAYCHEM Pyrotenax mineral insulated

(MI) industrial wiring cables must be installed

in accordance with the requirements of national

and local codes and standards, the installation

instructions in this manual, and the customer’s

specification. Read these important safeguards and

carefully follow the installation instructions.

• Ensure the cable has been stored properly and is in

good condition prior to commencing installation.

• Always use safe working practices when installing

cables, observing OSHA and other national safety

rules.

• Store cables indoors in a clean, dry, covered area,

if possible.

• During the time that the cables are exposed and

during cable pulling activities, protect cables from

nearby or overhead work to prevent damage to the

cable sheath.

• Do not pull cables around corners that have sharp

edges, such as corners in cable trays, or other

obstructions.

• Prevent damage to cables by removing any

abrasions or sharp edges from surface of support

system.

• Damage to cables or components can cause

sustained electrical arcing or fire. Do not energize

cables that have been damaged. Damaged

cable or terminations may need to be repaired or

replaced. Damaged cable should be repaired by a

qualified person.

• When installing cables which may be exposed to

hydrocarbon flash fires, use only steel or stainless

steel in the support system.

ii | nVent.com

TABLE OF CONTENTS

1 General Information ....................................................1–2

1.1 Use of the Manual..........................................................1

1.2 Safety Guidelines ...........................................................1

1.3 Approvals........................................................................2

1.4 Warranty .........................................................................2

2 Introduction ................................................................3–4

2.1 General ...........................................................................3

2.2 Factory Terminated Cables ...........................................4

2.3 Field Terminated Cables................................................4

3 Storage and Handling................................................5–10

3.1 Storage ...........................................................................5

3.2 Handling .........................................................................7

4 Pre-Installation .......................................................11–14

4.1 Minimum Installation Temperature ............................11

4.2 Precautions ..................................................................11

4.3 Factory Terminated Cables .........................................12

4.4 Installation Equipment.................................................12

4.5 Set-Up ...........................................................................13

5 Installation..............................................................15–31

5.1 General Installation Guidelines ...................................15

5.2 Connection to Junction Boxes and

Other Equipment ..........................................................23

5.3 Installation in Hazardous Areas..................................26

5.4 Protecting the MI Cable Terminations

from Hydrocarbon Flash Fires ....................................28

5.5 Cable Terminations......................................................30

6 Testing and Commissioning ....................................32–35

6.1 Tests .............................................................................32

7 Troubleshooting Guide ............................................36–37

8 Appendixes .............................................................38–41

Appendix A: Improving Insulation Resistance ...................38

Appendix B: Cable Inspection Record ................................40

nVent.com | iii

iv | nVent.com

nVent.com | 1

1 GENERAL INFORMATION

1.1 Use of the Manual

This manual covers storage and installation of

PYROTENAX Alloy 825 Sheath MI industrial wiring cables.

It is assumed that the cables have been correctly sized

and the installation properly designed. Installers must be

trained and familiar with relevant codes and standards

and generally accepted good practice for handling and

installing power cables. For installations or situations that

are not covered in this guide, please contact nVent for

guidance.

For additional information, contact:

nVent

7433 Harwin Drive

Houston, TX 77036

USA

Tel +1.800.545.6258

Fax +1.800.527.5703

nVent.com

1.2 Safety Guidelines

The safety and reliability of an MI cable system depend on

the proper design and installation of the system and use of

proper materials for support, as well as the quality of the

cable selected. Incorrect design or installation or use of

inappropriate support materials can result in a system that

may not perform satisfactorily, and in the case of a fire-

rated system, it may not perform under fire conditions.

Install all wiring in accordance with the latest edition

of national electrical codes and standards, such as the

National Electrical Code (NEC) or Canadian Electrical Code

(CEC), and/or the Authority Having Jurisdiction and the

instructions in this manual.

• Notes are marked Note

• Important instructions are marked Important

• Warnings are marked WARNING

2 | nVent.com

1 GENERAL INFORMATION

1.3 Approvals

MI industrial wiring cables are manufactured in accordance

with international standards.

• Factory terminated cables are: cCSAus Certified

• Bulk cable is: cULus Listed and cCSAus Certified

• Field installed termination kits for bulk cable are:

cCSAus Certified

Note: ATEX certified terminations also available.

1.4 Warranty

nVent's PYROTENAX MI wiring products Limited Warranty

applies to these products. For details, see the complete

warranty on our web site at nVent.com.

Important: For the nVent warranty and agency

approvals to apply, the instructions that are included

in this manual and product packages must be followed.

nVent.com | 3

2 INTRODUCTION

2.1 General

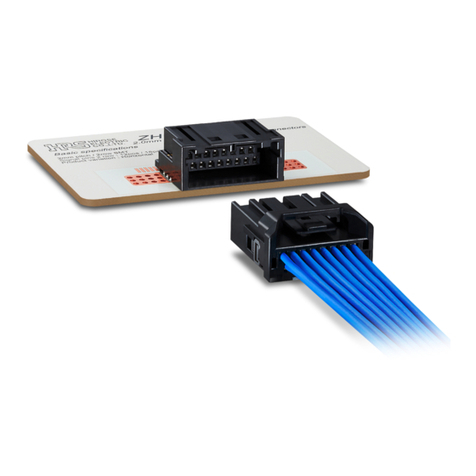

PYROTENAX MI industrial wiring cable is manufactured

with nickel-clad copper or nickel conductors within a

robust Alloy 825 sheath, embedded in highly compacted

magnesium oxide insulation (Figure 1). This construction

and the nature of the inorganic materials used provide MI

cables with characteristics that surpass those of other

cable types without the need for additional protection such

as conduit. One of the most exceptional qualities of MI

cable is its fire resistance—the cable will not burn, support

combustion, propagate flame, or emit smoke or toxic

gases.

MI cable can be used for indoor and outdoor applications

in industrial installations. It is extensively used in

petrochemical plants where the integrity of power and

control wiring to emergency block valves and emergency

equipment must be maintained during a hydrocarbon flash

fire. The solid construction of MI cable makes it suitable

for use in hazardous areas to prevent the passage of

explosive gases. In addition, it is used in pulp and paper

plants, electricity generation plants, and in mines and

manufacturing where resistance to extreme heat and

corrosion is required. For further information on using and

installing MI cable, refer to the applicable sections of the

NEC / CEC or other national electrical codes and standards

if outside the US and Canada.

Solid nickel-clad copper

or nickel conductors

Magnesium oxide (MgO)

insulation

Alloy 825 sheath

Figure 1: MI industrial wiring cable

2 INTRODUCTION

2.2 Factory Terminated Cables

Factory terminated cables can be connected as received to

junction boxes and other equipment. The standard factory

termination utilizes the epoxy sealing compound shown in

Figure 22 on page 30. The cables are supplied with a metal

identification tag showing the cable specifications and

approvals.

2.3 Field Terminated Cables

Cables that are to be terminated in the field are supplied

with temporary heat shrinkable end caps that seal the

ends against moisture ingress. Field installed termination

kits are available with the epoxy sealing compound or

gray sealing compound shown in Section 5.5, page 30

and 31, and should be selected based on the application.

Identification tags are not supplied.

4 | nVent.com

3 STORAGE AND HANDLING

The rugged construction of PYROTENAX MI industrial

wiring cable makes it the perfect solution for all industrial

applications, no matter how extreme. However, certain

storage and handling guidelines should be followed to

minimize the possibility of damage to the cable.

3.1 Storage

To protect cables from physical damage and the

environment, inspect the cables upon receipt and observe

the following storage measures.

Initial Inspection

When the cables are received:

• Inspect the factory-applied protective covering on the

cable for evidence of shipment damage. Keep the

protective cover in place until removal is absolutely

necessary.

• Where possible, check the cable sheath for evidence of

shipment damage.

• Verify that terminations or heat shrinkable end caps are

not damaged, missing, or removed.

• Verify that factory terminated cables are correctly

labeled and have the appropriate gland connector

fittings for the intended use.

• Check the insulation resistance (IR) for the presence of

moisture in the cable using a megohmmeter (damage

to the sheath, end caps, or terminations will cause

moisture to enter the cable). See Section 6 for testing

guidelines and record the results of the tests in the

Cable Inspection Record in Appendix B. If moisture is

present, follow the instructions in Appendix A to remove

the moisture or contact nVent for guidance.

nVent.com | 5

3 STORAGE AND HANDLING

Storage Measures

• Store all cables indoors in a clean, dry location, if

possible, and protect from moisture, construction

equipment, falling objects, chemical spills, moving

vehicles, and other hazards.

• Store factory terminated cables in a manner that

prevents damage to the sealing pot and flexible tails.

• Do not remove the heat shrinkable end caps from bulk

cable until the cable is ready to be terminated.

• Do not stack coils or reels.

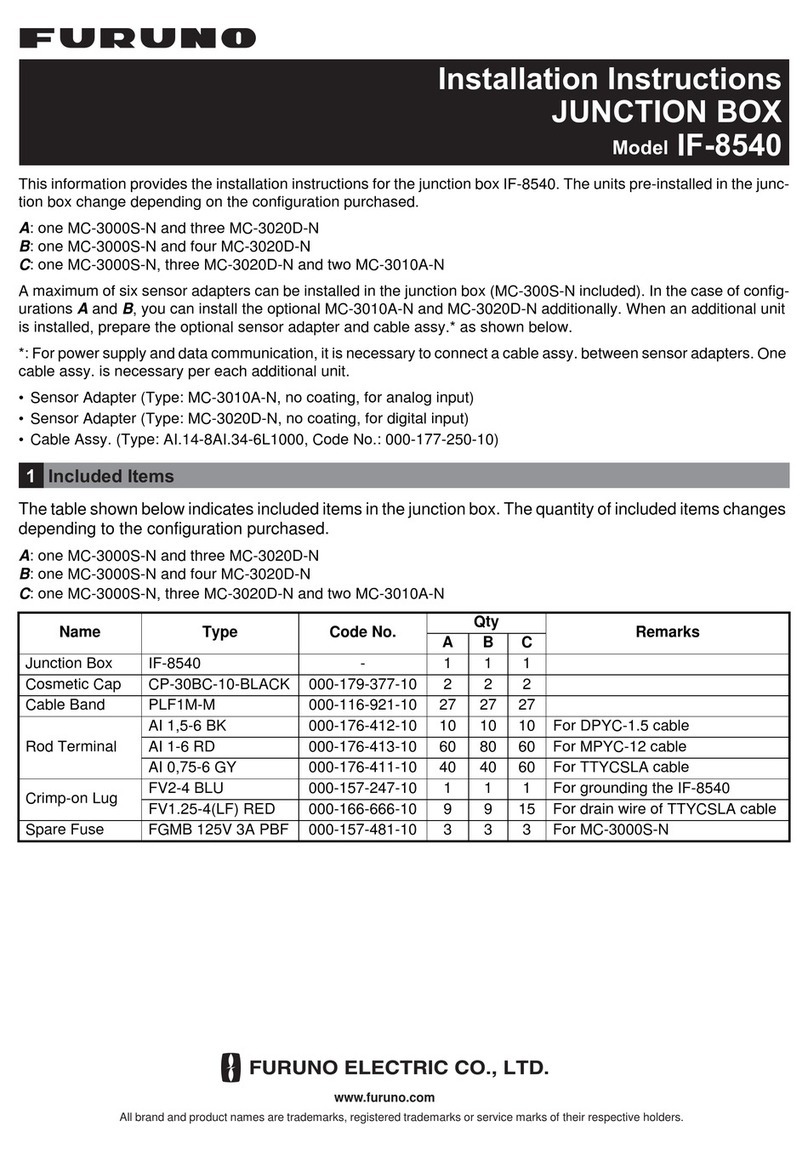

• Do not store coils or reels flat. Store coils upright and

reels upright on their flanges (Figure 2).

• Ensure that both ends of the cable are securely

fastened to the reel flange.

• Store reels on a firm surface, paved if possible, or on

planking to prevent reels from rotting.

Always load and store reels

upright on their flanges and

block securely.

Laying heavy reels flat

can cause damage.

Right Wrong

Figure 2: Store reels upright on flanges

6 | nVent.com

3 STORAGE AND HANDLING

3.2 Handling

Moving Coils and Reels

• Handle and install cables within suitable temperature

limits (See Section 4.1, page 11).

• Handle coils and reels utilizing equipment designed for

that purpose.

• Do not drop coils or reels from any height, particularly

from trucks or other transporting equipment.

• Lift or handle coils and cable reels in such a manner

that the lifting / handling device does not make direct

contact with the cable or its protective covering. Coils

should be placed on a skid.

• Handle reels in a manner that prevents deterioration of

and physical damage to the reel and to the cable.

• Take precautions to ensure that the flange of one reel

does not impact the cable on another reel.

Note: If a coil or reel is dropped or the protective

covering is damaged, examine the cable for damage.

Refer to Section 7 for the Troubleshooting Guide.

Damaged cables may need to be repaired or replaced.

Contact your local representative for more information.

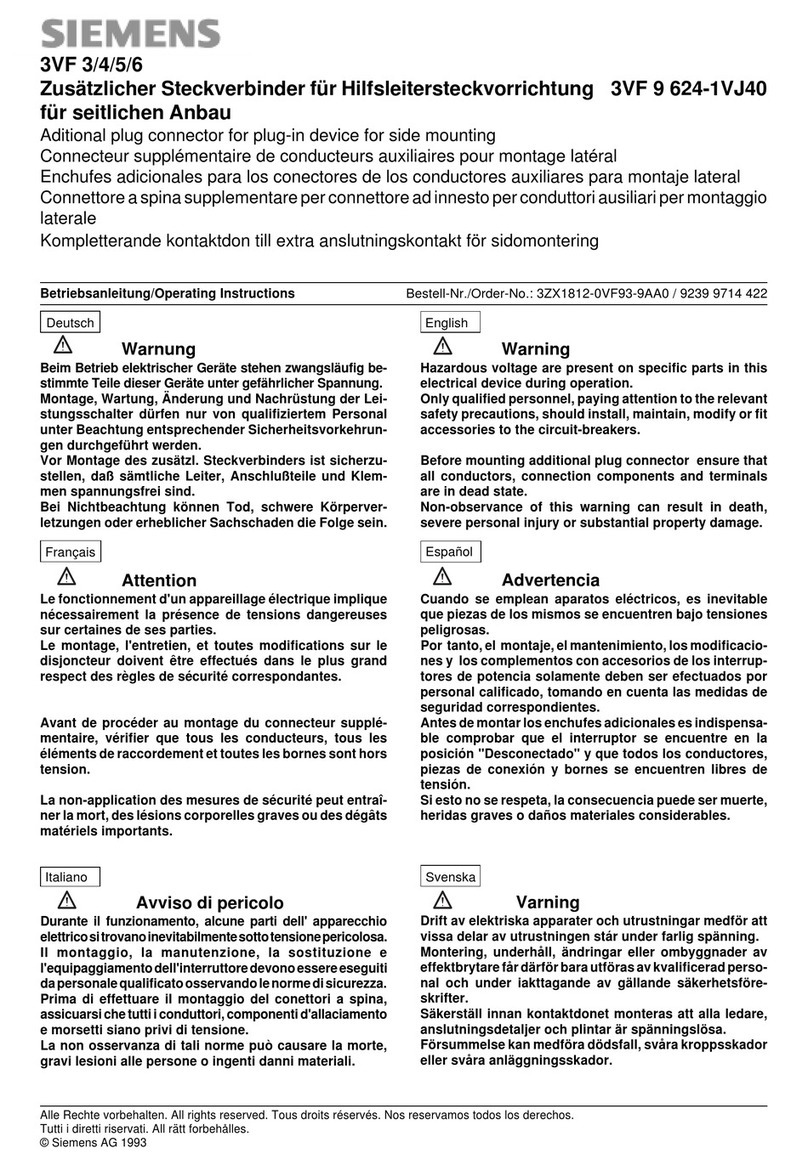

The following lifting methods for reels are recommended

(Figure 3):

• Insert a suitable properly-secured shaft through the reel

arbor hole and lift with slings using a crane or boom-

type equipment. Use a spreader or other device to

minimize sling pressure against the reel flange.

• Move smaller, narrower reels using a forklift. Place fork

tines so that lifting pressure is on both reel flanges, not

on the cable.

nVent.com | 7

Lower reels from a truck using

a hydraulic gate, hoist or fork

lift. LOWER CAREFULLY.

Right Wrong

Reels can be hoisted with a

properly secured shaft extending

through both flanges.

Cradle both reel flanges

between fork tines.

Never drop reels.

Do not lift by a single reel

flange. Cable or reel may be

damaged.

Never allow fork tines to touch

the cable surface or reel wrap.

Figure 3: Reel handling DOs and DON’Ts

3 STORAGE AND HANDLING

8 | nVent.com

3 STORAGE AND HANDLING

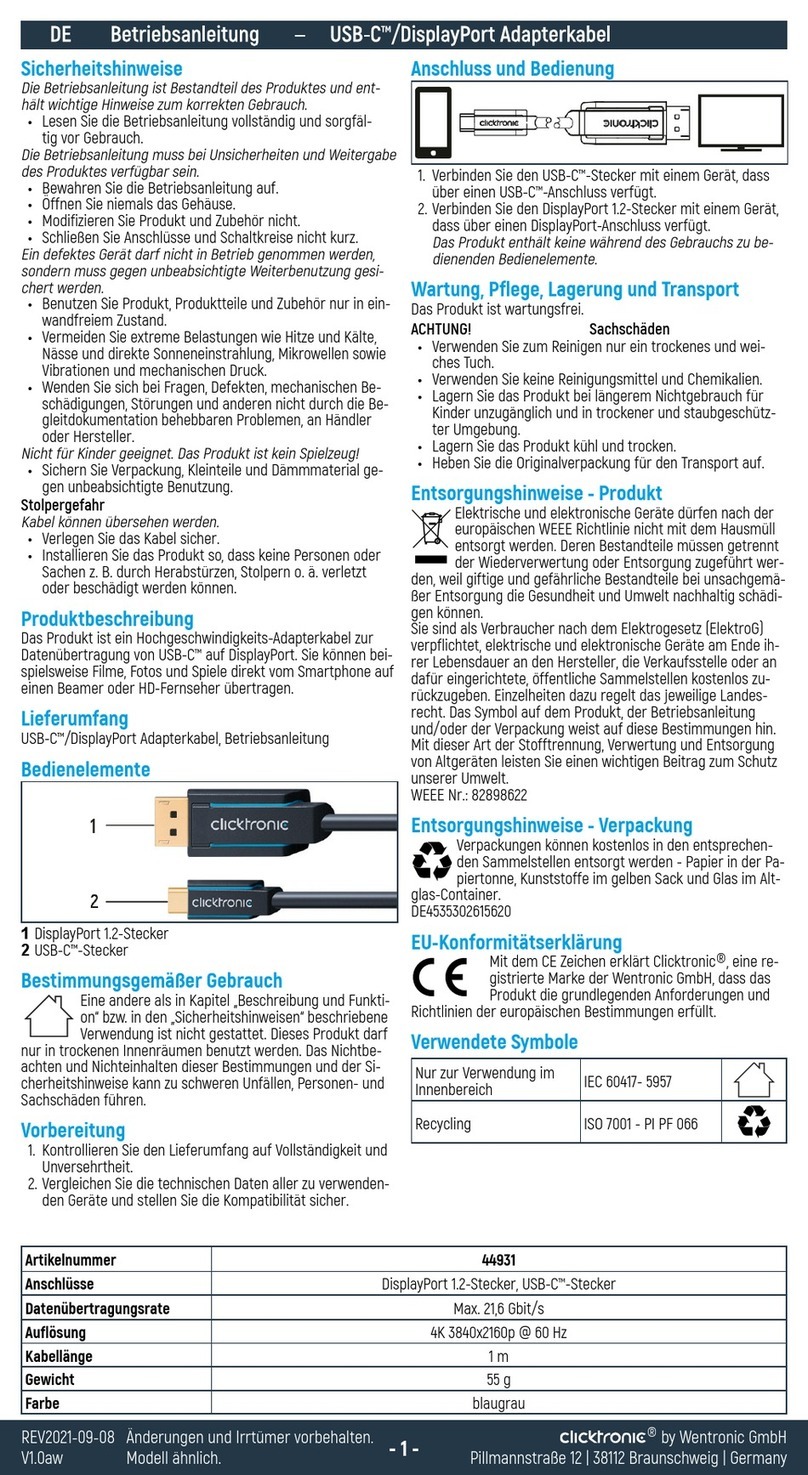

• Roll reels to move them short distances and in the

direction so that the cable does not unwind (Figure 4);

this will tighten the cable windings, not loosen them.

It is recommended that surfaces over which the reels

are rolled be firm, level, and clear of debris that may

damage the cable.

Roll reel in the direction

indicated by the arrow.

Figure 4: Reel rolling

Uncoiling Cable

• Do not uncoil cable or transfer cable to another reel

prior to installation as it will become work hardened,

making it less easy to install.

• Support reel on a jack stand when uncoiling; cables

supplied in coils may be fed from a pay-off reel

(Figure 5). Have someone rotate the reel or coil to feed

the cable as it is being pulled. This will greatly ease the

handling and prevent possible twisting, bending, and

kinking.

• Use appropriate precautions when uncoiling cable (see

Section 4.2, page 11).

• Handle cable carefully during uncoiling to prevent

damage due to kinking, or bending to a radius smaller

than the minimum pulling radius (see Table 2, page 18).

• Ensure that the cable is not twisted during installation.

• Do not run over cable, drag cable over sharp objects,

or subject cable to other such treatment that could

cause damage.

nVent.com | 9

Right Wrong

Right Wrong

Reel

Coil

Figure 5: Unreeling / uncoiling cable

3 STORAGE AND HANDLING

10 | nVent.com

4 PRE-INSTALLATION

Cable installations must be preplanned to ensure a

successful installation. It is important to ensure that

personnel are properly trained and qualified for the

specific task they are performing. All applicable rules and

regulations including federal, state / provincial, local, and

municipal laws must be followed. For further information

on installing MI cables, contact nVent Technical Support,

see Section1.1.

4.1 Minimum Installation Temperature

A minimum installation temperature of −40°F (−40°C) is

recommended for MI cables.

4.2 Precautions

When installing PYROTENAX MI industrial wiring cables,

all appropriate precautions should be followed, including

OSHA and other applicable national safety regulations.

Therefore, in addition to observing standard safety

practices, observe the following:

• Take reasonable precautions to prevent damage to the

cable from severe blows with sharp instruments and

pulling over sharp objects.

• Do not pull cables around corners that have sharp

edges, such as corners in cable trays, or other

obstructions.

• Pull all cable diameters, one at a time, by hand.

• Hand feed cables around corners using large sweeping

bends.

• When changing direction from horizontal to vertical,

use properly-sized sheaves or pulleys.

• Protect exposed cables from any nearby or overhead

work that could damage the cable.

• Do not pull cables around a radius smaller than the

minimum pulling radius (see Table 2, page 18).

• Make sure all equipment used during cable installation

is in good operating condition.

For further assistance on pulling cables, contact nVent

Technical Support, see Section 1.1.

nVent.com | 11

4 PRE-INSTALLATION

4.3 Factory Terminated Cables

Prior to installation of long runs of cable, attach a short

length of PVC conduit to the factory terminated ends to

provide protection for the sealing pot and flexible tails

(Figure 6). Use 1 in (25 mm) minimum PVC pipe, or larger

if a 1 in or 1-1/4 in (25 mm or 32 mm) gland connector is

supplied. This will prevent damage to the sealing pot and

tails during installation.

1" (25 mm) min

PVC pipe

Threaded

PVC end

Reducer (from PVC pipe

to gland connector)

Gland

connector

Factory-terminated

MI cable

Figure 6: Protecting sealing pot and flexible tails

4.4 Installation Equipment

Pulling Equipment

It is recommended that all sizes of cables be hand pulled

into position, one at a time, using pulling ropes securely

attached to the cable end. When pulling cables around

corners, hand feed cables using large sweeping bends.

Mechanical pulling equipment, such as tuggers, is not

recommended.

Sheaves

Use sheaves or pulleys of the proper diameter, where

required, to avoid damage to the cable.

Pulling Rope

Use non-stretch pulling rope with a capacity large enough

to handle the force required to pull the cable.

It is recommended that the pulling rope be attached to the

cable sheath using a series of six half-hitch knots, and the

knots and rope be securely taped to the sheath to prevent

movement during the pull.

When pulling cables from a factory terminated end, ensure

that the end is protected with a short length of PVC pipe

(see Figure 6, page 12) and securely attach the pulling

rope to the cable sheath to avoid damage to the

termination.

Install cable grips, swivels, and pulling eyes, if used,

according to manufacturer’s instructions.

12 | nVent.com

4 PRE-INSTALLATION

4.5 Set-Up

Examine cable trays, trapeze support systems, and other

support systems for acceptability prior to pulling activities.

Install permanent supports properly to ensure the rigidity

of the cable tray, trapeze, or other support system so that

neither the support system nor the cable will be subjected

to damage during the pulling process.

Before installation, verify that the cable(s) can be installed

according to the designed routing and minimum bending

radius requirements.

Where it is not practical to completely remove the cable

from the reel, set up the reel using sheaves or pulleys as

shown in Figure 7 on page 14. The first sheave must be

installed at a point higher than the support system. Use

a roller at the entry and exit points of the tray / trapeze

system. The setup should ensure that the cable is not

kinked or bent beyond the minimum pulling radius (see

Table 2, page 18) or subject to excessive twisting force.

Minimize the amount of tension necessary to pull a cable

as follows:

• Pull in the proper direction. Where practical, a cable pull

should begin nearest the end having the least degrees

of bends and exit the end having the greater degrees

of bends if at all possible. Also, in vertical sections, an

upward pull is preferred.

• Minimize the number and degrees of bends the cable

is pulled around under tension. Accomplish this by

finding the straightest route possible using the least

amount of bends.

nVent.com | 13

Sheave Roller

Right Wrong

Figure 7: Reel set-up

Station experienced cable pulling observers along the

route, in contact (visually, by radio, or by phone) with the

other members of the crew.

4 PRE-INSTALLATION

14 | nVent.com

5 INSTALLATION

Following these installation instructions will consistently

produce satisfactory MI cable installations. Further

information on proper installation techniques may be

obtained by contacting nVent Technical Support, see

Section 1.1.

5.1 General Installation Guidelines

• When subject to potentially damaging abuse, protect

the cable with a metal guard such as angle iron or steel

channel.

• Metal supports, cable sheath, and other metal

enclosures for the cables must be metallically joined

together and must be connected to all boxes, fittings,

and cabinets so as to provide effective electrical

continuity.

• Ensure that you do not invalidate the listing of

enclosures or other equipment if it is necessary to cut

holes.

Moisture Absorption

The magnesium oxide insulation of MI cable is

hygroscopic and can absorb moisture when exposed to air,

causing the IR to fall. Low IR can be corrected as outlined

in Appendix A.

Expansion and Vibration

Where cables may expand or contract due to temperature

changes, or when connecting the cable to vibrating

equipment, it may be necessary to take precautions to

prevent mechanical damage to MI cable. Refer to Section

5.2, page 23 and Section 5.3, page 26 for further details.

Equipment Bonding

The sheath of Alloy 825 MI cable must be bonded to

ground, but must not be used as the equipment-to-ground

bonding conductor. For proper equipment-to-ground

bonding, use one conductor within the sheath or use a

separate equipment-to-ground bonding conductor.

Straightening and Dressing the Cable

The cable may be straightened by hand or by using a dead

blow hammer and a block of wood as shown in Figure 8.

Do not use a metal hammer as it may result in unsightly

dents that cannot be removed. Once the cable has been

installed, the use of stainless steel banding or cable

clamps to strap the cable to the tray will help dress the

cable, maintaining a neat appearance.

nVent.com | 15

Wooden

blocks

Deadblow

hammer

Figure 8: Straightening and dressing MI cable

Bending Radius

The minimum bending radius for permanent training of

PYROTENAX MI cable is shown in Table 1, although it is

recommended that bends are kept as large as possible.

Where smaller bends are necessary, a conduit bending tool

(Figure 9) may be utilized, but care must be taken not to

bend the cables to less than the minimum bending radius.

Table 1: Minimum Bending Radius for Permanent Training

Cable O.D. (outside diameter)

0.75 in (19 mm) and smaller 6 times cable diameter

Larger than 0.75 in (19 mm) 12 times cable diameter

5 INSTALLATION

16 | nVent.com

Table of contents

Other Raychem Cables And Connectors manuals

Raychem

Raychem C25-100 User manual

Raychem

Raychem Gardian W51 User manual

Raychem

Raychem nvent MI Series User manual

Raychem

Raychem JBS-100-EP User manual

Raychem

Raychem IEK-25-04 User manual

Raychem

Raychem JBM-100-E User manual

Raychem

Raychem TRACETEK TT5000-HS User manual

Raychem

Raychem t-100 User manual

Raychem

Raychem RayClic-PC User manual

Raychem

Raychem TraceTek TT3000 SERIES User manual