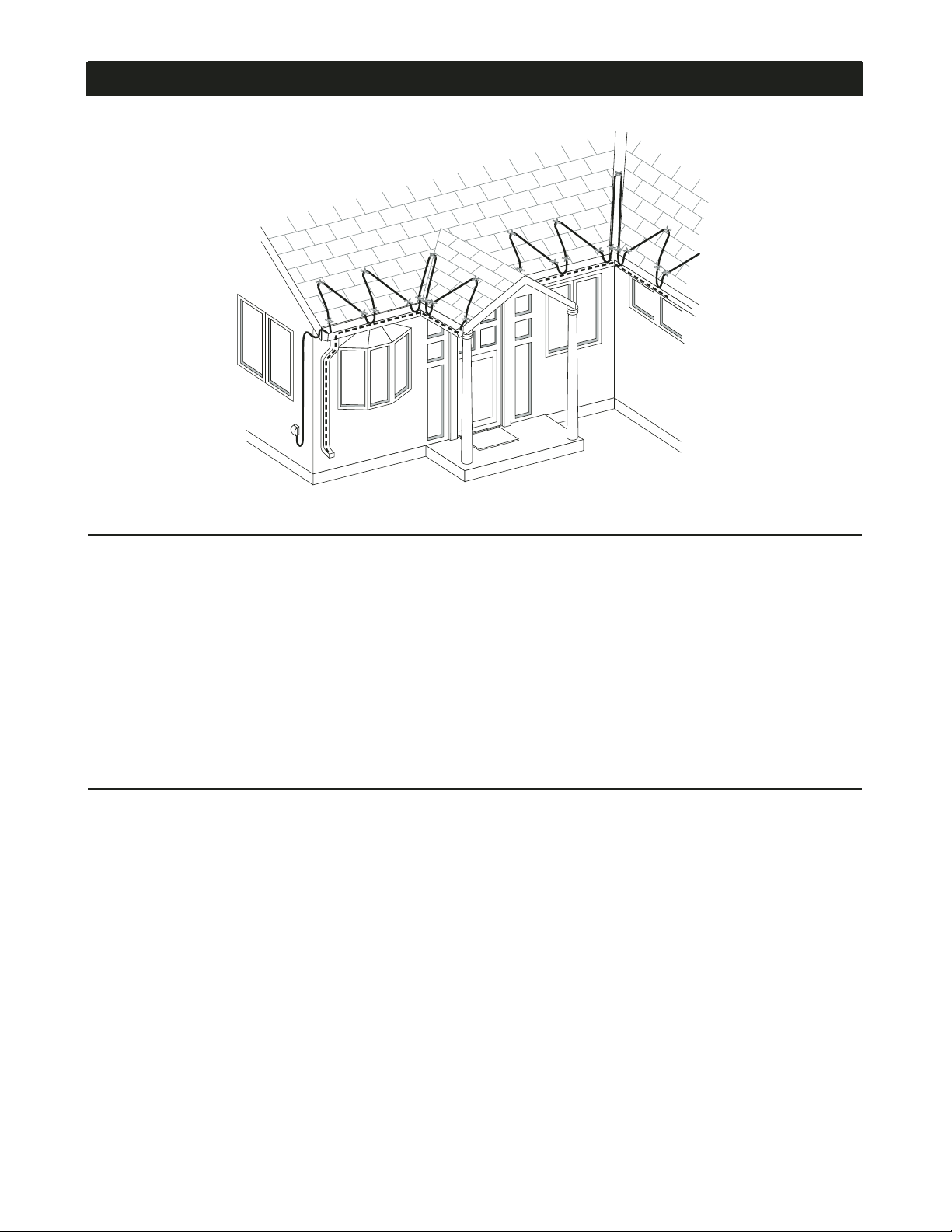

• For roofs without gutters, route the

heating cable as shown in Figure 7.

• Extend the top of each heating cable loop

beyond where the wall joins the roof.

• Trace two-thirds of the way up each valley

with a double run of heating cable as

shown in Figure 8.

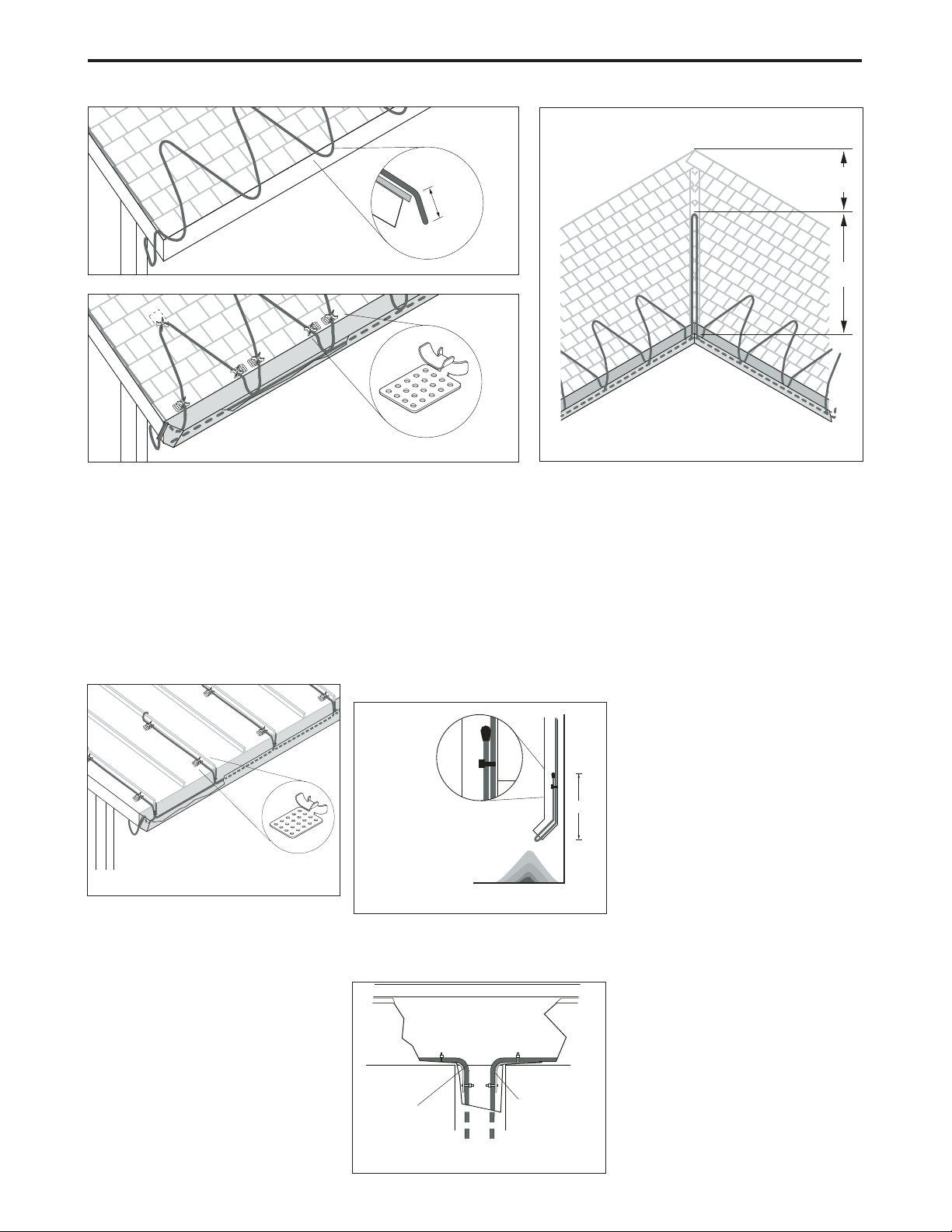

• Use H913/H914 roof clips to route heating

cable into and out of the gutter in such a

way as to prevent abrasion to the cable.

Protect all cable that protrudes past the

lower opening of the downspout.

• One H913 kit contains ten roof clips for

approximately 7 linear feet of roof edge.

One H914 kit contains 50 roof clips for

approximately 35 linear feet of roof edge.

• Roof clips may be attached to a shake or

shingle roof with nails or screws as shown

in Figure 9. Roof clips may be attached to

a metal roof using screw, nail or adhesive

as shown in Figure 10. (See H56723

installation instruction for more details.)

Reseal the nail or screw holes if necessary

before installing heating cable in the clips.

• A barrier (snow fence) can be placed on the

roof above the heating cable. This prevents

damage to the cable and keeps the

installation from coming loose due to ice

slides. The heating cable can be attached to

the barrier with UV-resistant cable ties,

instead of using roof clips, if desired. Do not

use wire or other materials because they

may damage the heating cable.

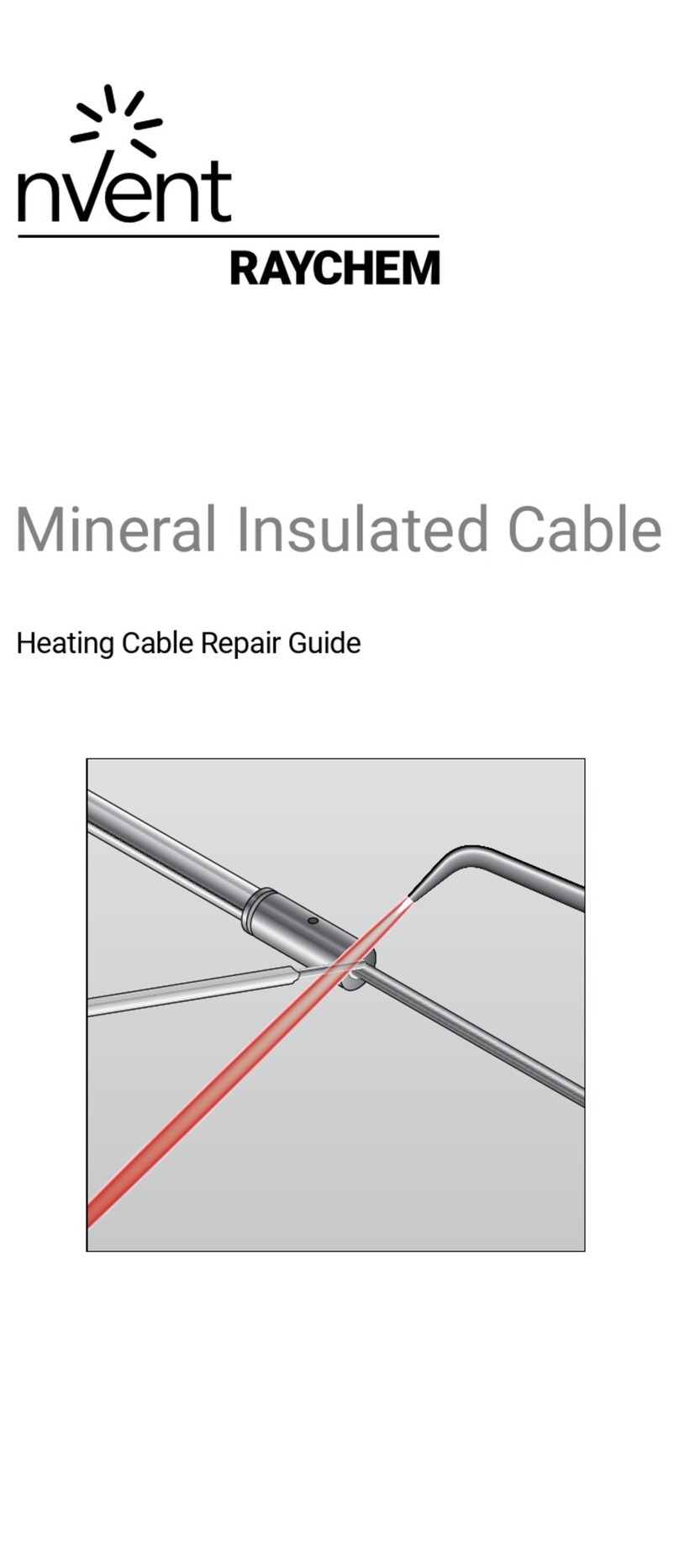

In gutters and downspouts

• Run heating cable along gutters and into

downspouts, ending below the freezing level.

Permanent attachment of the cable to the

gutter bottom is not necessary. Loop the

heating cable in downspouts. Do not leave

the end of the Gardian in air at the end of

the downspout as shown in Figure 11.

• Use H915 Hanger Brackets at the

gutter/downspout transition to protect the

heating cable from fraying and from

damage from sharp edges and to provide

strain relief as shown in Figure 12. Refer

to the H915 kit instructions for installation

details.

• Route and secure cable to avoid possible

mechanical damage, such as from ladders,

etc.

3. Mark the installation.

Two labels indicating the presence of

electric de-icing and snow-melting

equipment on the premises are included

with the heating cable. One label must be

posted at the electrical outlet cover. The

other label must be posted at the fuse or

circuit breaker panel. The labels must be

clearly visible.

4.Check the installation.

• Prior to plugging in, check to be sure the

heating cable is free of mechanical damage

(cuts, clamps, etc.).

• Using a megohmmeter, test each circuit

according to the instructions in the

“Heating cable testing and maintenance”

section on next page.

5.Starting the system.

• Tyco Thermal Controls recommends that

the system be tested per the “Cable

testing and maintenance” section below.

• Plug the heating cable into a 120 V

ground-fault protected outlet.

• Check the circuit breaker to verify power

to the cable.

7