UMHPI Industrial inverter air/water heat pumps with axial fans

2

INDEX

1CONSERVATION OF THE MANUAL ...................................................................................................................................... 4

1.1 GRAPHIC SYMBOLS USED IN THE MANUAL ............................................................................................................................ 4

2PERMITTED USES................................................................................................................................................................ 4

3GENERAL SAFETY GUIDELINES ............................................................................................................................................ 4

3.1 PERSONAL PROTECTION EQUIPMENTS.................................................................................................................................. 4

3.2 HEALTH AND SAFETY OF WORKERS........................................................................................................................................ 5

4PURPOSES AND CONTENTS OF THE MANUAL...................................................................................................................... 5

5SYSTEM ARCHITECTURE ..................................................................................................................................................... 6

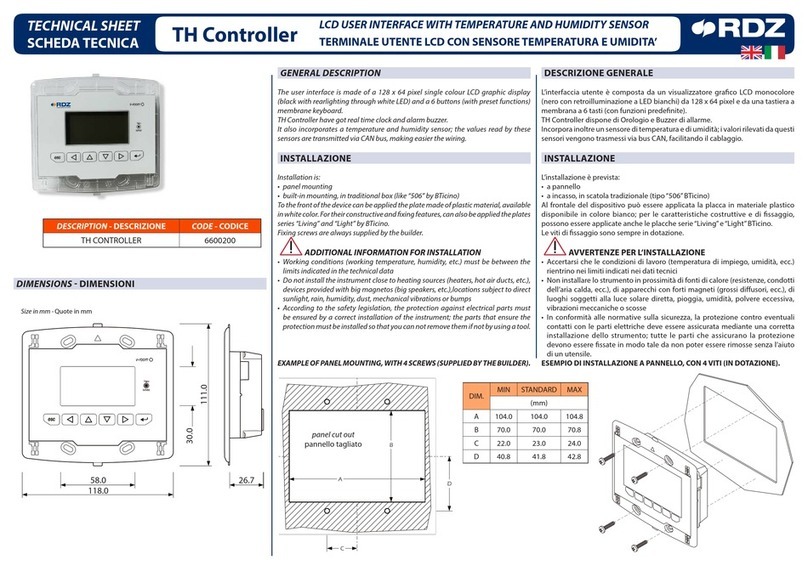

6USER – CB MASTER CONTROLLER INTERFACE...................................................................................................................... 7

6.1 MENU STRUCTURE DIAGRAM ................................................................................................................................................ 7

6.2 ANALOG INPUTS..................................................................................................................................................................... 8

6.3 PARAMETERS CATEGORIES .................................................................................................................................................... 8

6.4 ADJUSTABLE SETPOINT BY THE USER ..................................................................................................................................... 8

6.4.1 DISPLAY .......................................................................................................................................................................... 9

6.4.2 LED.................................................................................................................................................................................. 9

6.5 INPUT/OUTPUT (I/O) PORTS .................................................................................................................................................. 9

7OPERATION LOGIC ............................................................................................................................................................10

7.1 DYNAMIC SETPOINT ADJUSTMENT ...................................................................................................................................... 10

7.2 SETPOINT ADJUSTMENT FROM 0-10V INPUT....................................................................................................................... 11

7.3 CIRCOLATOR......................................................................................................................................................................... 11

7.3.1 OPERATION BY MEAN OF THE THERMOREGULATOR (Default).................................................................................... 12

7.3.2 OPERATION UNDER THERMOREGULATOR CALL WITH PERIODIC ACTIVATION ........................................................... 12

7.3.3 OPERATION WITH ACTIVE ELECTRIC HEATER ............................................................................................................... 12

7.3.4 CONTINUOUS OPERATION ........................................................................................................................................... 12

7.3.5 LINEAR ADJUSTMENT OF THE CIRCULATING PUMP–DOUBLE WATER ΔT.................................................................... 12

7.4 MULTICOMPRESSORS .......................................................................................................................................................... 13

7.4.1 LOGIC OF ACTIVATION.................................................................................................................................................. 13

7.4.2 LOGIC OF RELEASE........................................................................................................................................................ 13

7.4.3 CAPACITY CONTROL ..................................................................................................................................................... 13

7.4.4 EMERGENCY CONDITIONS............................................................................................................................................ 14

7.4.5 DHW LOGIC CONTROL.................................................................................................................................................. 14

7.4.6 DEFROST FUNCTION CONTROL .................................................................................................................................... 14

7.4.7 INVERTER COMPRESSOR CONTROL IN COOLING MODE .............................................................................................. 14

7.4.8 HEATING FUNCTION CONTROL .................................................................................................................................... 14

7.4.9 TRANSITORY OF STARTING........................................................................................................................................... 15

7.5 HEAT DISSIPATION FAN MOTOR CONTROL .......................................................................................................................... 15

7.5.1 FAN SPEED CONTROL ................................................................................................................................................... 15

7.5.2 FAN SPEED CONTROL IN COOLING MODE.................................................................................................................... 15

7.5.3 FAN SPEED CONTROL IN HEATING MODE .................................................................................................................... 16

7.6 MODULATION FOR OIL RETURN........................................................................................................................................... 16

7.7 DEFROSTING CYCLE.............................................................................................................................................................. 16

7.7.1 DEFROST OPERATION SIGNALIZATION ......................................................................................................................... 16

7.8 ALARM NOTIFICATION ......................................................................................................................................................... 17

7.9 SUMMER/WINTER OPERATION NOTIFICATION FUNCTION ................................................................................................. 17

7.10 COMPRESSOR CRANCKASE HEATER ..................................................................................................................................... 17

7.11 ANTIFREEZE PROTECTION ELECTRIC HEATERS (IF THE KA ACCESSORY IS PRESENT) ............................................................. 17

7.12 ACTIVATION OF DOMESTIC HOT WATER PRODUCTION ....................................................................................................... 17

7.12.1 MEMORY OF THE SENSOR IN HEATING MODE............................................................................................................. 18

7.13 HEATING MODE ON DOMESTIC HOT WATER TANK.............................................................................................................. 19

7.14 REMOTE FUNCTIONS............................................................................................................................................................ 20

7.14.1 ON/OFF......................................................................................................................................................................... 20

7.14.2 SUMMER/WINTER MODE COMMUTATION ................................................................................................................. 20

7.14.3 SANITARY MODE CALL FROM DIGITAL INPUT .............................................................................................................. 20

7.15 PLANT CIRCUIT REMOTE SENSOR......................................................................................................................................... 21

7.16 VAPOR INJECTION (ONLY FOR VVERSION)................................................................................................................................. 21

7.16.1 Main circuit VEE, Double control.................................................................................................................................. 22