RealFlame Vektor 1100 User manual

Other RealFlame Indoor Fireplace manuals

RealFlame

RealFlame Crawford 8020E-W User manual

RealFlame

RealFlame T9650 LP User manual

RealFlame

RealFlame Ignite RF XLF50 User manual

RealFlame

RealFlame 11622LP User manual

RealFlame

RealFlame 6030 User manual

RealFlame

RealFlame LANDSCAPE 1000 User manual

RealFlame

RealFlame 11564LP1 User manual

RealFlame

RealFlame Mantel 8090E User manual

RealFlame

RealFlame 11624LP User manual

RealFlame

RealFlame 9605 LP User manual

RealFlame

RealFlame 26100244 User manual

RealFlame

RealFlame 3750 User manual

RealFlame

RealFlame 7100 User manual

RealFlame

RealFlame 8500 User manual

RealFlame

RealFlame Firebox 4099 User manual

RealFlame

RealFlame 2085 User manual

RealFlame

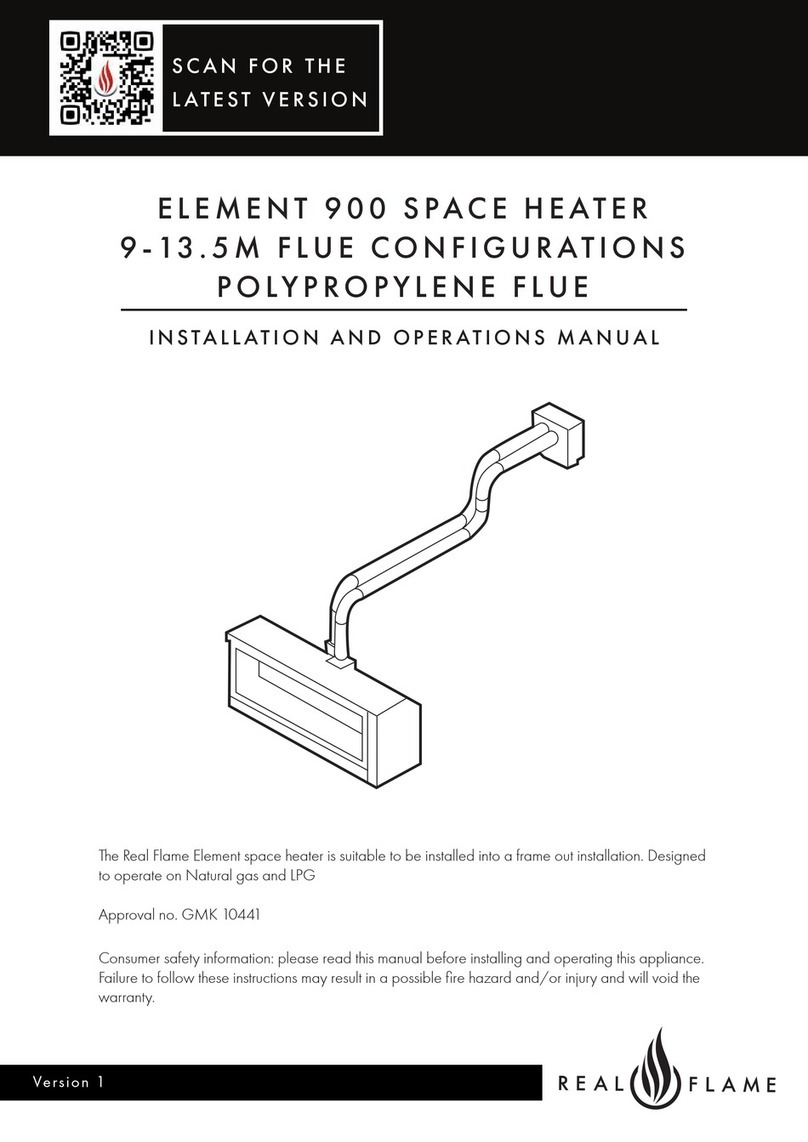

RealFlame ELEMENT 900 User manual

RealFlame

RealFlame Silverton G8600 User manual

RealFlame

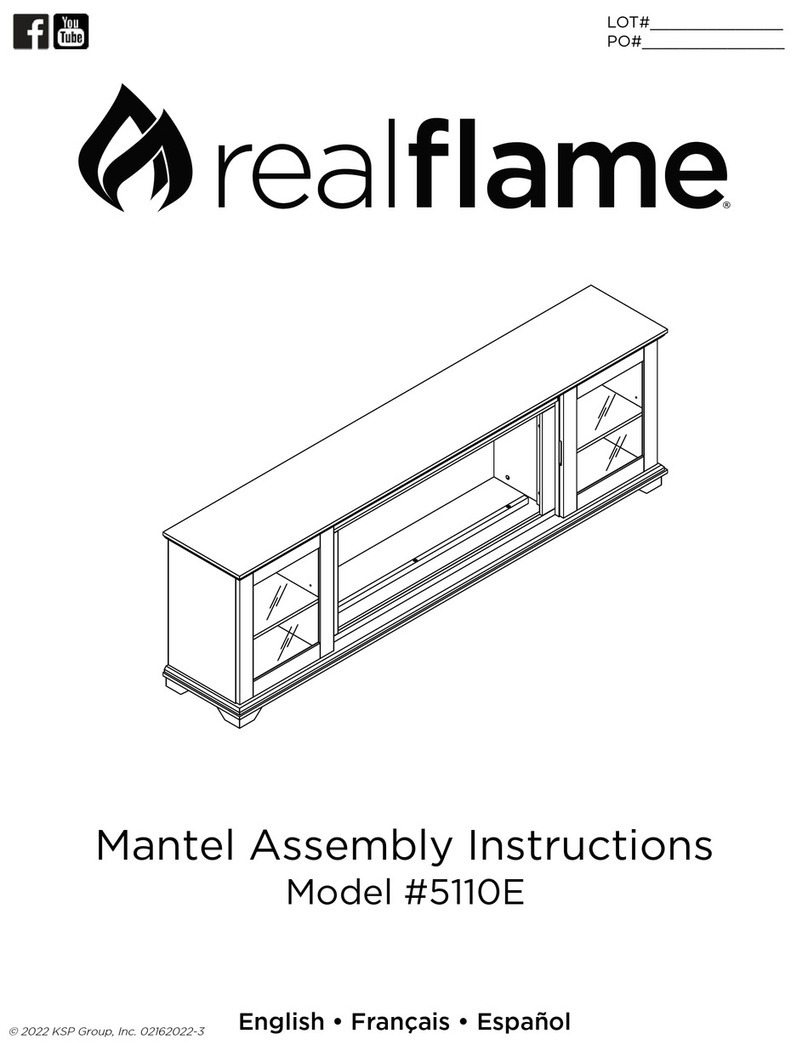

RealFlame Benjamin 5110E User manual

RealFlame

RealFlame Mantel 2770 User manual

Popular Indoor Fireplace manuals by other brands

Brigantia

Brigantia 35-DVRS31N-2 User's installation, operation and maintenance manual

Nordpeis

Nordpeis Bergen Installation and user manual

Superior

Superior BCT2536TMN Installation and operation instructions

Quadra-Fire

Quadra-Fire 5100I-GD-B owner's manual

Renaissance

Renaissance RUMFORD 1000 user manual

Lacunza

Lacunza IV-800 Instruction book

Baxi

Baxi 940 Installer and owner guide

Dru

Dru Maestro 60/2 Tall RCH installation manual

Diamond Fireglass

Diamond Fireglass SS-O22 General assembly, installation, and operation instructions

HearthStone

HearthStone Windsor Bay 8830 Owner's manual and installation guide

Napoleon

Napoleon ASCENT B42 quick start guide

Enviro

Enviro E33GI owner's manual

Smeg

Smeg L30 FABE Installation & user's instructions

KEDDY

KEDDY K700 Installation instructions care and firing instructions

Godin

Godin 3451 manual

Jøtul

Jøtul Jotul GI 535 DV IPI New Harbor Installation and operation instructions

Desa

Desa CCFPDFT Owner's operating & installation manual

Miles Industries

Miles Industries Vogue 1300IRN Installation & operating instructions