1

Contents

1 General Description ........................................................................................................3!

1.1 Features ................................................................................................................3!

1.2 Main Application and Testing Range ..................................................................4!

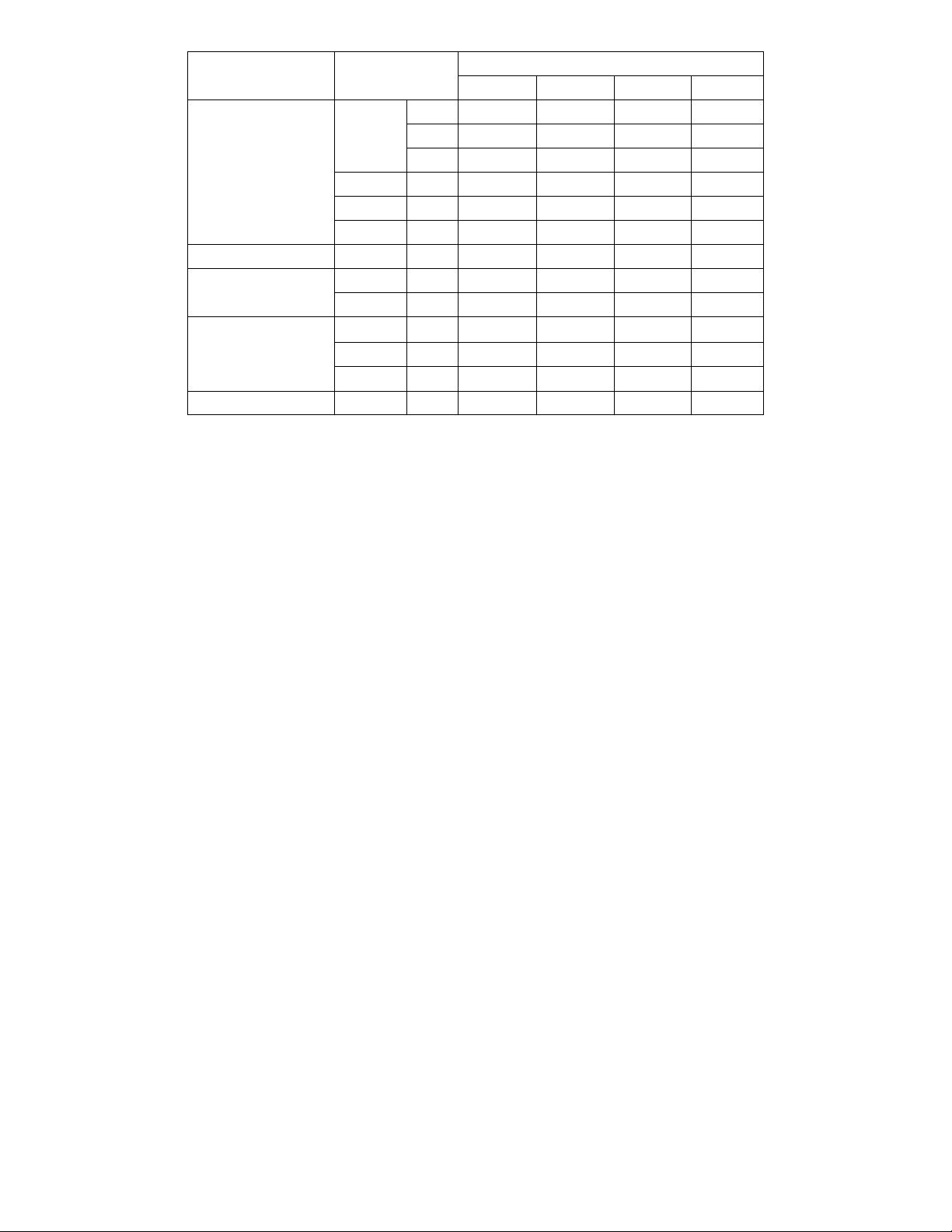

1.3 Types and specification........................................................................................8!

1.4 Operating conditions:.........................................................................................10!

2 Structure features and Testing principle .......................................................................11!

2.1 Structure features ...............................................................................................11!

2.2 Testing principle ................................................................................................12!

3 Technical capabilities....................................................................................................12!

3.1 Specifications .....................................................................................................12!

4 Testing...........................................................................................................................16!

4.1 Preparation and Inspection prior to testing ........................................................16!

4.2 Testing................................................................................................................19!

5 Special prompts.............................................................................................................23!

6 Operation detail.............................................................................................................23!