Rev 05 Page6

5.9 Rider Instructions..................................................................................................................22

5.10 Emergency Stop Procedure...................................................................................................22

5.11 Personal Protective Equipment (PPE)...................................................................................23

5.11.1 Personal Flotation Devices (PFD’s)................................................................................24

5.11.2 Immersion Suits ............................................................................................................25

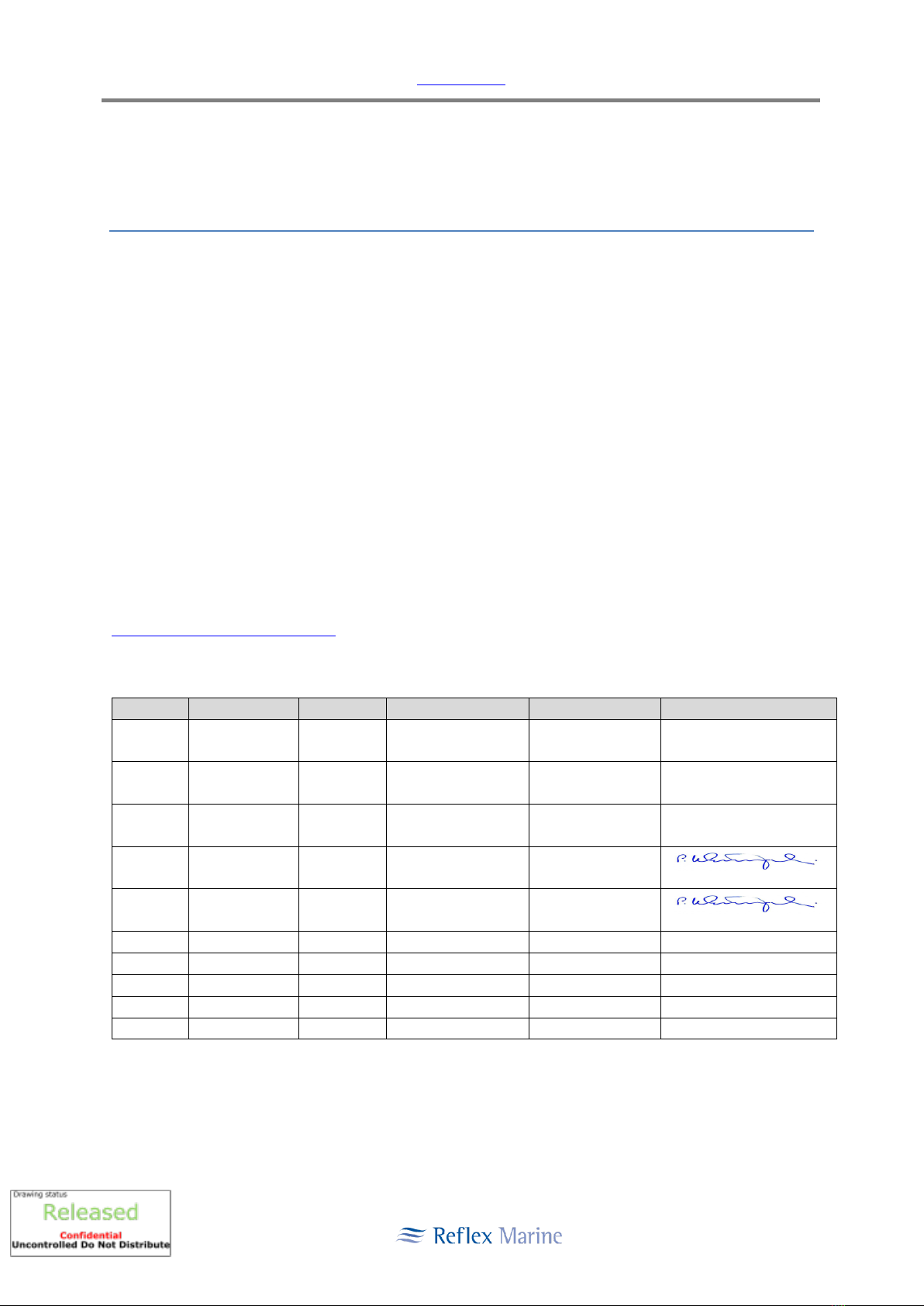

6 PERIODIC INSPECTION, TESTING AND MAINTENANCE.................................................................26

6.1 Introduction ..........................................................................................................................26

6.2 Definitions.............................................................................................................................26

6.3 Frequency of Inspection, Test and Maintenance..................................................................27

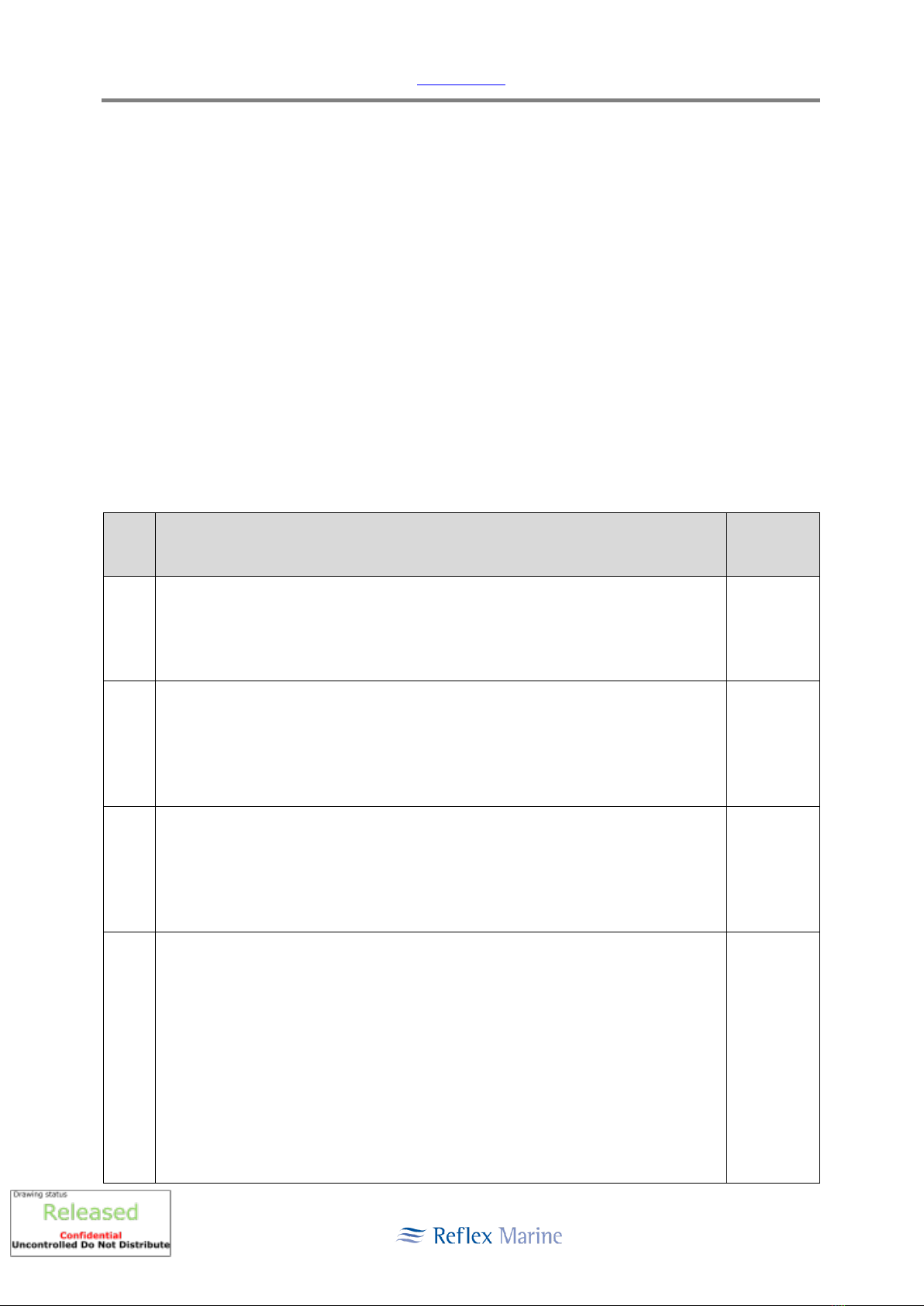

6.4 Pre-Operational Visual Check ...............................................................................................29

6.5 Visual Inspection ...................................................................................................................31

6.6 Examination ..........................................................................................................................34

6.7 Post Load Test Visual Inspection...........................................................................................38

6.8 Proof Load Testing ................................................................................................................41

6.8.1 Load Test Procedure .....................................................................................................42

6.8.2 Test Plate.......................................................................................................................42

6.9 Sling Replacement and Management...................................................................................43

6.9.1 Sling Set (Critical Part) Replacement.............................................................................43

6.9.2 Sling Set Management ..................................................................................................43

6.10 Critical Spares Kits and Replacement Parts ..........................................................................44

6.10.1 Spares Kits.....................................................................................................................44

6.10.2 All Other Replacement Parts.........................................................................................45

6.11 Unit Replacement Recommendation....................................................................................45

7 UNIT IDENTIFICATION ...................................................................................................................47

7.1 Product ID Numbers..............................................................................................................47

7.2 Part Numbers........................................................................................................................47

7.3 FROG-9 Serial Numbers ........................................................................................................47

7.4 Component Serial Numbers..................................................................................................47

8 HANDLING, SHIPPING AND STORAGE...........................................................................................48

8.1 Dimensions............................................................................................................................48

8.2 Handling & Transportation ...................................................................................................48

8.2.1 Forklift...........................................................................................................................48

8.2.2 Crane.............................................................................................................................48

8.2.3 Securing.........................................................................................................................48

8.2.4 Inspection......................................................................................................................48

8.2.5 Preparation for Road Transport....................................................................................48

8.2.6 Containerisation............................................................................................................48

8.2.7 Storage ..........................................................................................................................49

9 APPENDIX A –TRANSFER LOG.......................................................................................................50

10 APPENDIX B –DRAWINGS.............................................................................................................51

11 APPENDIX C –PARTS LIST AND MATERIAL SPECIFICATIONS.........................................................57

11.1.1 Definition According to Criticality.................................................................................57

11.1.2 Fastener Specifications .................................................................................................57

11.1.3 Certification...................................................................................................................57

12 APPENDIX D –FROG-9 MARKINGS................................................................................................60