Rev 3.1 2 | P a g e

Contents

Introduction...........................................................................................................1

1Product Specifications .....................................................................................4

2Operating Parameters .....................................................................................5

2.1 General ................................................................................................................................................. 5

2.2 Recommended Operating Parameters............................................................................................. 7

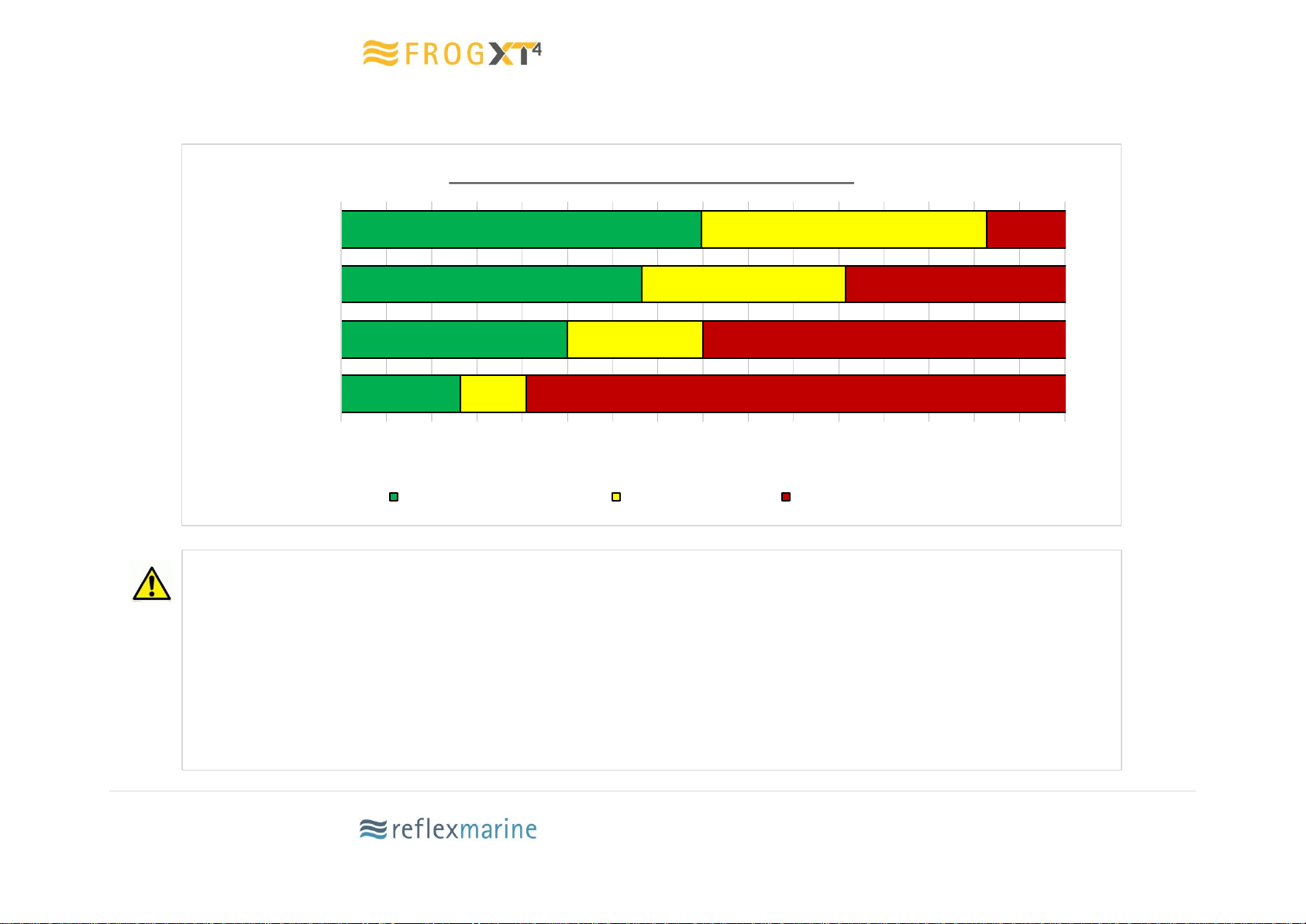

2.3 Crane Transfer Planning Tool............................................................................................................ 7

3Using the FROG-XT ..........................................................................................8

3.1 Safety Features ................................................................................................................................... 8

3.2 Passenger Instructions....................................................................................................................... 8

3.3 Entry and Exit...................................................................................................................................... 9

3.4 Deck Crew Instructions.................................................................................................................... 10

3.5 Passenger Instructions..................................................................................................................... 11

3.6 Stretcher Mode.................................................................................................................................. 12

3.7 Carrying Luggage.............................................................................................................................. 13

3.8 Lifting Assembly Connection ........................................................................................................... 14

3.9 Control of Lifting Assembly.............................................................................................................. 15

4Inspection & Maintenance.............................................................................16

4.1 Definitions .......................................................................................................................................... 16

4.2 Care in use / Preventative maintenance........................................................................................ 16

4.3 Inspection Types............................................................................................................................... 18

4.4 Frequency .......................................................................................................................................... 18

4.5 Supporting Documentation.............................................................................................................. 19

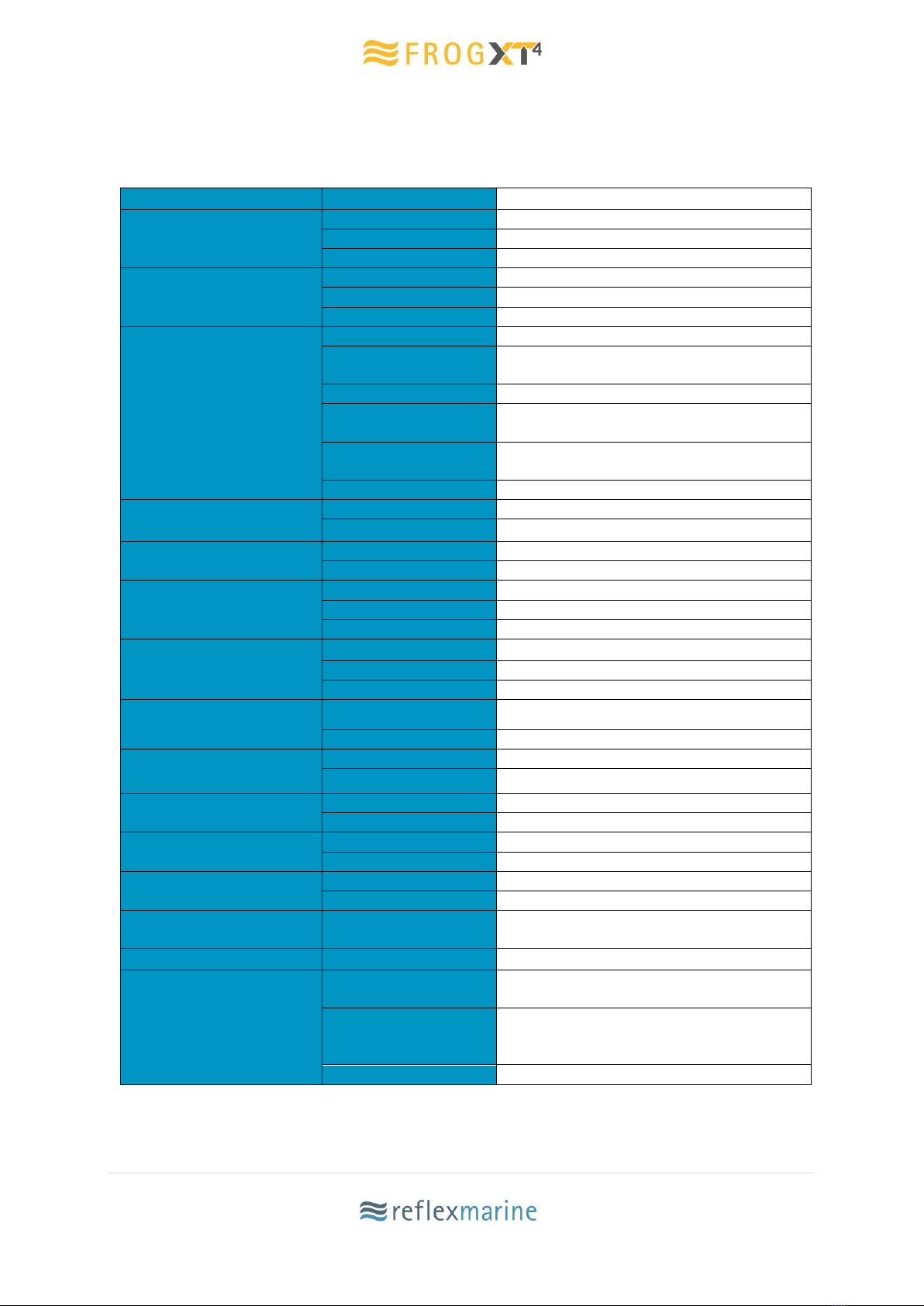

4.6 FROG-XT4 Inspection and Maintenance Schedules ..................................................................... 20

Ultra-High Usage............................................................................................................................................ 21

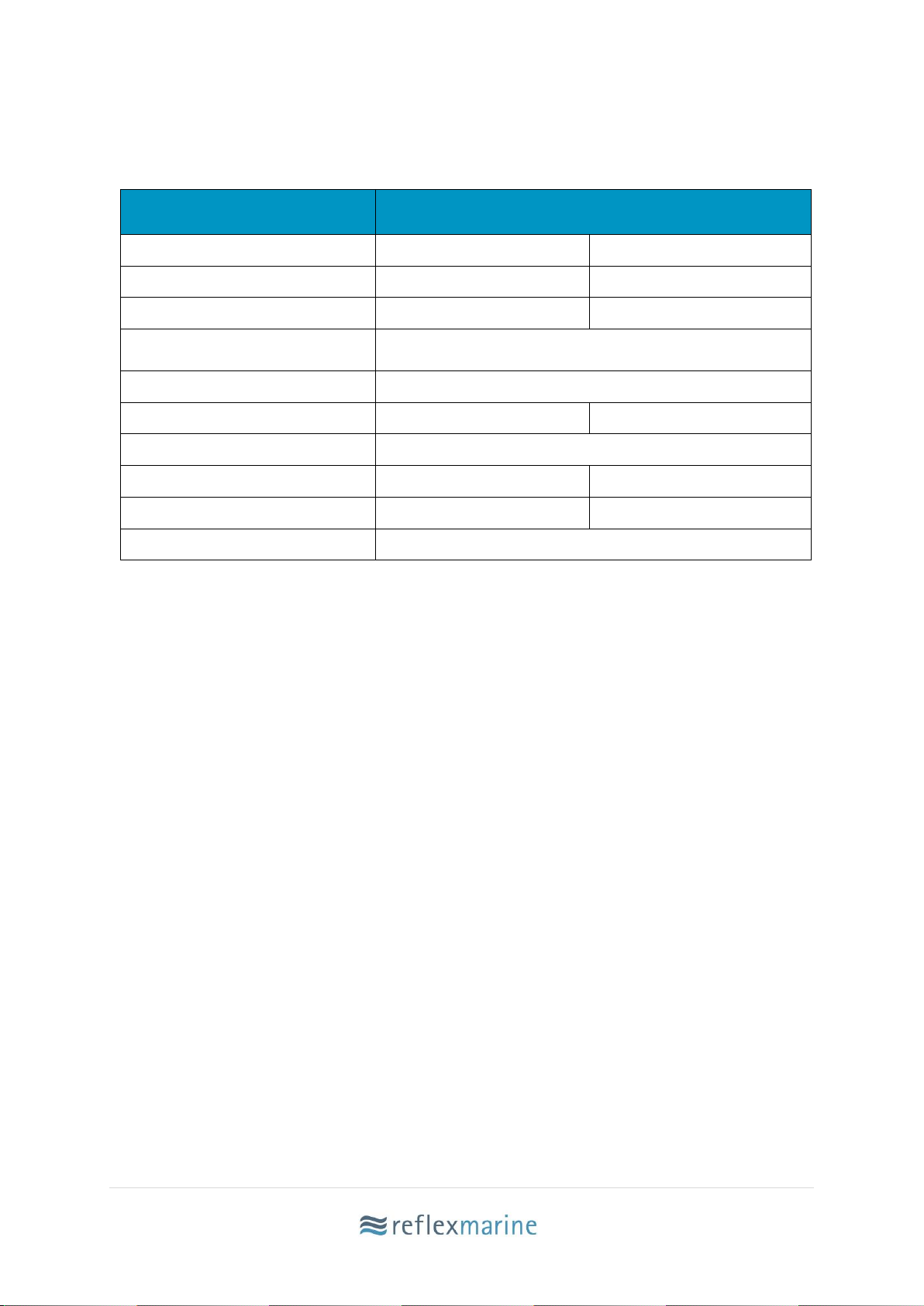

4.7 Load Test Procedure ........................................................................................................................ 22

4.8 Data Plates......................................................................................................................................... 23

4.9 Pre-Use Check ................................................................................................................................... 24

4.10 Visual Inspection Checklist Form .................................................................................................... 25

4.11 Examination Checklist Form ............................................................................................................ 28

4.12 Post Load Test Inspection Checklist Form .................................................................................... 32

5Handling & Storage........................................................................................33

5.1 Stock Inspections.............................................................................................................................. 33

5.2 Forklift ................................................................................................................................................ 34

5.3 Crane .................................................................................................................................................. 34