Installation

Model F4FR-NF sprinklers are intended to be installed

in accordance with NFPA 13, FM Global Property Loss

Prevention Data Sheets, and the requirements of applicable

authorities having jurisdiction.

Do not install The Non-Ferrous Concealer™ in ceilings which

have positive pressure in the space above. In addition,

inspect all sprinklers after installation to ensure that both the

gap between the cover plate and ceiling and the four (4) slots

in the cup are open and free from any air flow impediment.

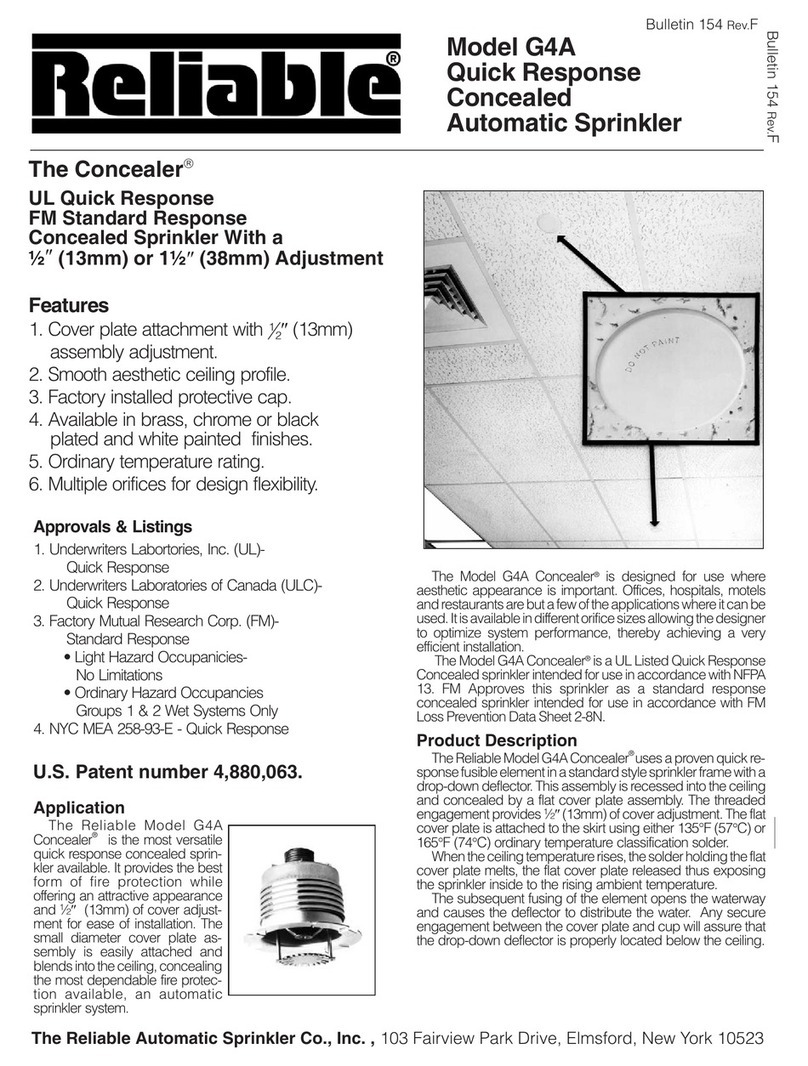

After a 2-5/8” diameter hole is cut in the ceiling, the sprinkler

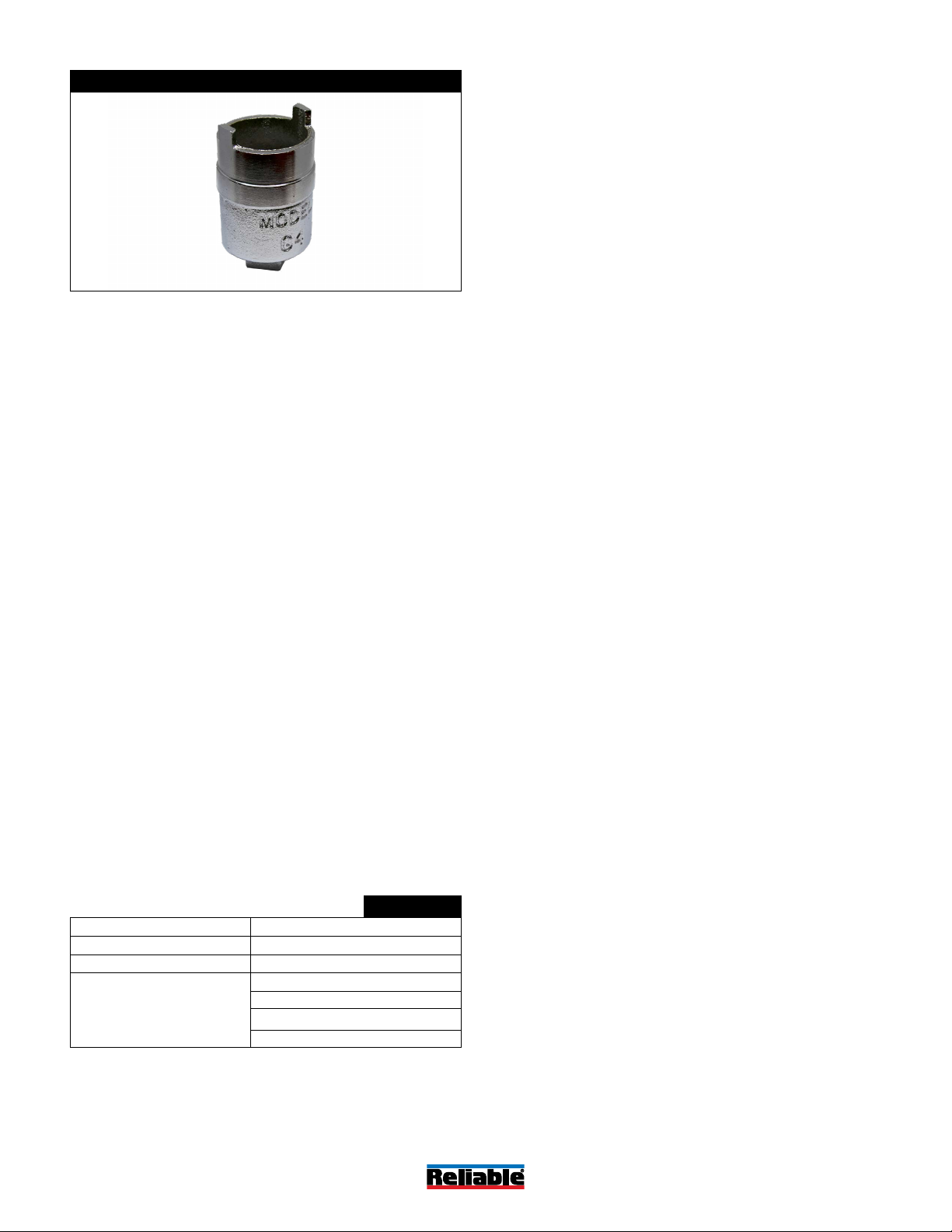

is installed with the Model G4 Wrench. When installing a

sprinkler, the wrench is first positioned into the sprinkler/cup

assembly until two wrench tangs fully engage drive slots in the

top of the cup (there are two pairs of drive slots in the cup).

The sprinkler is then tightened into the pipe fitting to a torque

of 8 to18 ft-lbs (11 to 24 N.m). Do not exceed the maximum

recommended torque. Excessive torque may cause leakage

or impairment of the sprinkler.

When inserting or removing the wrench from the sprinkler/

cup assembly care should be taken to prevent damage to the

sprinkler. DO NOT WRENCH ON ANY OTHER PART OF THE

SPRINKLER/CUP ASSEMBLY. Replace any sprinklers that

have been damaged.

Install the cover plate by hand, pushing and then turning the

cover in the clockwise direction until it is tight against the

ceiling.

G4 Wrench

Standard Finishes Special Application Finishes

Chrome Bright Brass

White Finished Bronze

Black Plated

Black Paint

Off White

Chrome Dull

*Note: Other finishes and colors are available on special

order. Consult factory for details. Cover plate custom paint is

semi-gloss, unless specified otherwise.

Cover Plate Finishes* Table B

Maintenance

Reliable Model F4FR series sprinklers should be inspected

and the sprinkler system maintained in accordance with NFPA

25, as well as the requirements of any Authorities Having

Jurisdiction.

Prior to installation, sprinklers should remain in the original

cartons and packaging until used. This will minimize the

potential for damage to sprinklers that could cause improper

operation or non-operation.

Do not clean sprinklers with soap and water, ammonia

liquid or any other cleaning fluids. Remove dust by gentle

vacuuming without touching the sprinkler.

Replace any sprinkler which has been painted (other than

factory applied). A stock of spare sprinklers should be

maintained to allow quick replacement of damaged or

operated sprinklers. Failure to properly maintain sprinklers

may result in inadvertent operation or non-operation during a

fire event.

Guarantee

For the Reliable Automatic Sprinkler Co., Inc. guarantee, terms,

and conditions, visit www.reliablesprinkler.com.

Ordering Information

Specify:

Sprinkler

• F4FR-NF

Temperature

•

135°F (57°C)

• 155°F (68°C)

Cover Plate Finish

• See Table B

Sprinkler Wrench

•Model G4

Note: Paint or any other coatings applied over the factory

finish will void all approvals and warranties.

Bulletin 002

September 2020

Page 3 of 3

www.reliablesprinkler.com

P/N 9999970241