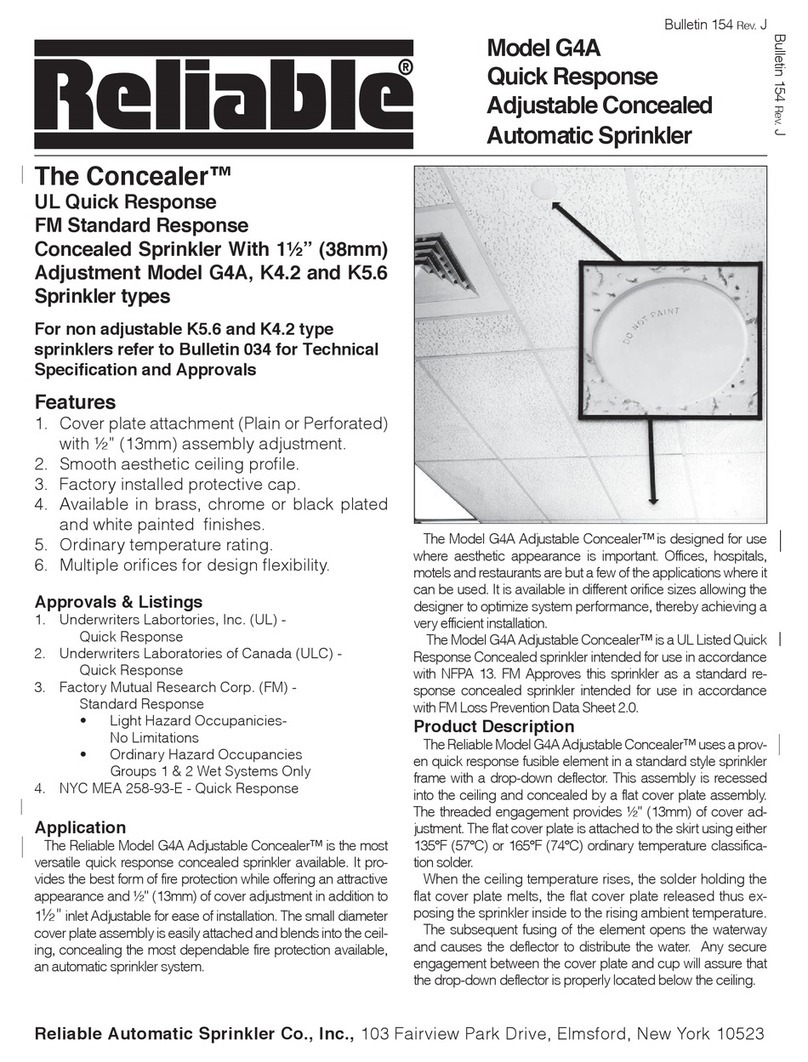

Optional Cover Plate with Gasket*

Model G4/G5

QR Gasket

Cover Plate

(cULus Listed)

Model G4/G5 SR Gasket

Cover Plate

(FM Approved)

* Model G4/G5 QR Gasket and Model G4/G5 SR Gasket cover

plates are sold as assembled units including both the cover

plate and gasket. Model G4 /G5 QR Gasket and Model G4 /G5

SR Gasket cover plates and gaskets are not interchangeable.

Installation Instructions

Model G5-56 Dry sprinklers must only be installed in stan-

dard (ANSI B 16.3 class 150 and ANSI B 16.4 class 125)

pipe tees in the horizontal position, even at branch line ends.

Model G5-56 Dry sprinklers shall not be installed into elbows

or pipe couplings located on drop nipples to the sprinklers.

In all installations, including into CPVC piping, the dry sprin-

kler shall be installed with protrusion into the fitting in accor-

dance with the installation diagrams in this Bulletin.

Installation of the Model G5-56 Dry sprinkler is not recom-

mended in copper pipe systems, as this may reduce the

life expectancy of the sprinkler. Do not install Model G5-56

Dry sprinklers with the standard (long) inlet fitting into CPVC

adapter fittings or tees that have an internal obstruction (see

Fig. 3); this will damage the sprinkler, the fitting, or both. A

short inlet (“PL”) version of the Model G5-56 Dry sprinkler is

available for use in existing installations with CPVC adapter

fittings or tees having an internal obstruction; Model G5-56

sprinklers with the short inlet fitting shall not be used on dry-

pipe sprinkler systems. The Model G5-56 Dry sprinkler and

the cover plate assembly are not intended for installation in

corrosive environments, including, but not limited to, those

with salt aerosols or chlorine.

Model G5-56 Dry sprinklers must be installed with the Ex-

posed Minimum Barrel Length required by Fig. 2 located in

a Heated Area. Do NOT install the sprinkler in ceilings which

have positive pressure in the space above.

The following steps must be followed for

installation:

1. Cut a 25

/

8-inch (67mm) diameter hole in the ceiling di-

rectly in-line with the outlet of the tee.

2. Apply pipe joint compound or Polytetrafluoroethylene

(PTFE) tape to the threads of the sprinkler’s inlet fitting.

3. A protective cap is provided to protect the drop-down

sprinkler deflector from damage which could occur dur-

ing construction before the cover plate is installed. The

cap is factory installed inside the sprinkler cup. Remove

the cap to install sprinkler, Step 4, then reinstall cap until

the cover plate is installed.

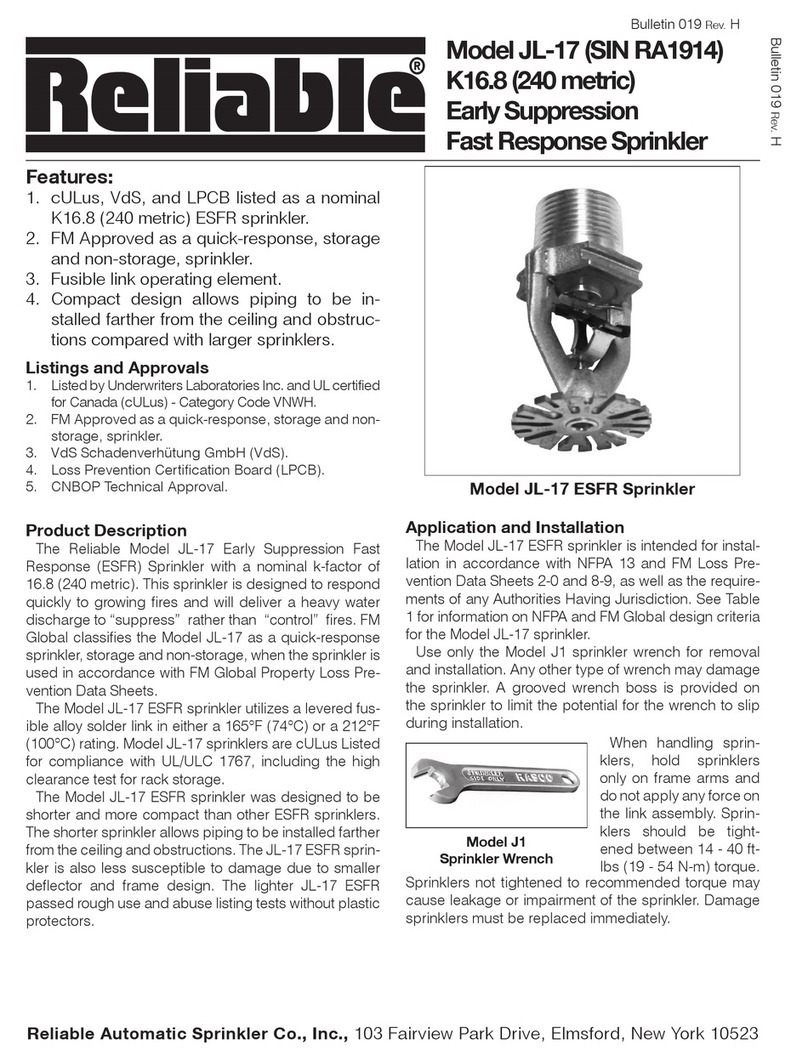

4. Install the sprinkler in the tee using the Model FC

wrench. The Model FC wrench has a socket drive which

is inserted into the sprinkler’s cup and around the body

of the sprinkler prior to installation of the sprinkler. Do

NOT wrench any of the part of the sprinkler/cup assem-

bly. The sprinkler is then tightened into the pipe fitting

to achieve a leak free connection. The recommended

minimum to maximum installation torque is 22-30 lb-ft

(30 – 40 N-m). When inserting or removing the wrench

from the sprinkler/cup assembly, care should be taken

to prevent damage to the sprinkler. Reinstall the protec-

tive cap following installation of the sprinkler, until the

cover plate is installed.

a. Alternatively, where access to the outer tube of the

sprinkler is available, the Model G5-56 Dry sprin-

kler may be installed using a pipe wrench. The

protective cap should not be removed to install

the sprinkler with a pipe wrench. The pipe wrench

shall only be permitted to interface with the steel

outer tube portion of the sprinkler (Item #8 in

Fig. 4). Do NOT wrench any other portion of the

sprinkler/cup assembly. A pipe wrench can install

the sprinkler into the fitting with a large amount

of torque; consideration should be given to the

need for future removal of the sprinklers because

the installation torque will have to be matched or

exceeded to remove the sprinkler. The recom-

mended minimum to maximum installation torque

is 22-30 lb-ft (30 – 40 N-m).

5. To install the cover plate, remove the protective cap and

install the cover plate by hand turning the cover in the

clockwise direction until it is tight against the ceiling. For

Model G4 /G5 QR Gasket and Model G4 /G5 SR Gas-

ket cover plates, the gasket should be attached to the

flange of the cover plate skirt only. Do not glue the gas-

ket in place or allow the gasket to overlap both the cover

plate and the flange of the skirt.

Model FC

Sprinkler Wrench

3.

Cover Plate Finishes

Standard Finishes

White Paint

Chrome

Special Application

Finishes

Off White Paint

Black Paint

Custom Color Paint – Specify(1)

Raw Brass (Lacquered)

Bright Brass

Finished Bronze

Black Plated

Satin Chrome

Stainless Steel Clad(2)

(1) Custom color paint is semi-gloss, unless specified otherwise.

(2) Stainless steel clad cover plates are Type 316 Stainless Steel on the finished

side and C102 Copper Alloy on the back side. Cover plates are not listed

or approved as corrosion resistant. Stainless steel clad cover plates are not

available perforated.