2

Listings and Approvals

1. Listed by Underwriters Laboratories, Inc. and UL certified

for Canada (cULus).

2. FM Approved as a quick-response, storage and non-

storage, sprinkler (FM).

3. VdS Schadenverhütung (VdS).

4. Loss Prevention Certification Board (LPCB).

5. CNBOP-PIB Technical Approval.

Specific Application Listing

In addition to design criteria permitted by NFPA 13, the Model

HL22 also has the following Specific Application Listing from UL:

Sprinkler: Model HL22 in 212 °F (100 °C) only

Maximum Ceiling Height: 48 ft (14.6 m)

Maximum Storage Height: 43 ft (13.1 m)

Minimum Aisle Width: 8 ft (2.44 m)

Permitted Commodities: Class I - IV commodities, encap-

sulated or nonencapsulated, and Cartoned Group A Unex-

panded plastics. Permitted Storage Arrangements: Single-

and double-row rack storage (no open top containers or

solid shelves) and palletized and solid pile storage (no open

top containers or solid shelves).

Minimum System Operating Pressure: 55 psi (3.79 bar).

Installation and Obstruction Criteria: Same as for

K25.2 ESFR sprinklers, but with a maximum deflector to

ceiling distance of 14" (356 mm)

Maintenance

The HL22 Sprinkler should be inspected and the sprinkler

system maintained in accordance with NFPA 25. Do not clean

sprinklers with soap and water, ammonia or any other cleaning

fluids. Remove dust by using a soft brush or gentle vacuuming.

Replace any sprinkler that has been painted (other than factory

applied) or damaged in any way. A stock of spare sprinklers

should be maintained to allow quick replacement of damaged

or operated sprinklers. Prior to installation, sprinklers should be

maintained in the original cartons and packaging until used. This

will minimize the potential for damage to sprinklers that would

cause improper operation or non-operation.

Engineering Specification Model HL22 ESFR

Sprinklers shall be Early Suppression Fast Response (ESFR)

pendent suppression mode sprinklers cULus Listed and FM,

VdS, and LPCB Approved for commodity storage applications.

Sprinkler frame and deflector to be of bronze construction

with deflector located inside of the frame arms. Sprinkler shall

have a maximum listed/approved ceiling-to-deflector distance

of 18". [Sprinklers shall have a UL Listed Specific Application

criteria permitting single- and double-row rack storage (no open

top containers or solid shelves) and palletized and solid pile

storage (no open top containers or solid shelves) of Class I-IV

commodities encapsulated or nonencapsulated and cartoned

Group A unexpanded plastics stored up to 43 ft (13.1 m) under

ceilings up to 48 ft (14.6 m) high when installed with 8 ft. aisles,

a minimum operating pressure of 55 psi (3.79 bar), a maximum

deflector to ceiling distance of 14" (356 mm), and a temperature

rating of 212 °F (100 °C).]

Fusible alloy solder link assembly shall utilize the strut and

lever principle of operation with approved fast response

beryllium-nickel thermal element with protective [black painted

(165 °F)] [white painted (212 °F)] coating. Water seal shall

consist of a Teflon-coated Belleville spring washer and brass

cap assembly containing no plastic parts. ESFR sprinklers

shall have a nominal K-Factor of 22.4 and [1" NPT][ISO7-R1]

threaded end connections. Sprinkler temperature rating shall be

[Ordinary 165 °F (74 °C)] [Intermediate 212 °F (100 °C)]. ESFR

pendent sprinklers shall be Reliable Model HL22, SIN RA1011

(Bulletin 010).

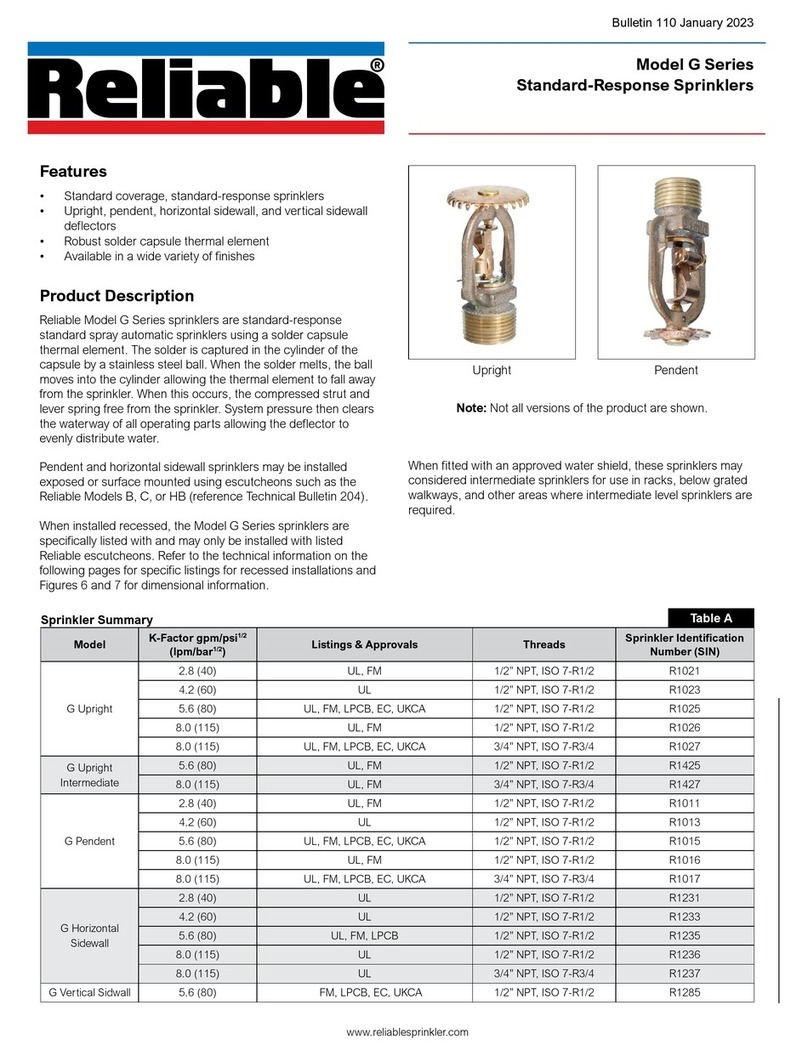

Model HL22 Temperature Ratings and Approvals

Temperature

Classification

Temperature

Rating Link

Color Frame

Color

Maximum Ceiling

Temperature Approvals Sprinkler

Identification No.

(SIN)

°F °C °F °C

Ordinary 165 74 Black Uncolored 100 38 cULus, FM, VdS,

LPCB, CNBOP RA1011

Intermediate 212 100 White White 150 66 cULus & UL Spec App,

FM, VdS, LPCB, CNBOP RA1011

Installation Data

Sprinkler Type Nominal Orifice Thread Size Nominal K‑Factor Maximum Working

Pressure

US Metric

Pendent 0.87"

(22.1 mm) 1" NPT

ISO7-R1 (Optional) 22.4 320 175 psi

(12.1 bar)