Installation

Do not install The Non-Ferrous Concealer®in ceilings

which have positive pressure in the space above. In addition,

inspect all sprinklers after installation to ensure that both the

gap between the cover plate and ceiling and the four (4) slots

in the cup are open and free from any air flow impediment.

After a 258

²diameter hole is cut in the ceiling, the sprinkler

is to be installed with the Model G4 Wrench. When installing a

sprinkler, the wrench is first positioned into the sprinkler/cup

assembly until two wrench tangs fully engage drive slots in

the top of the cup (there are two pairs of drive slots in the cup).

The sprinkler is then tightened into the pipe fitting to a torque

of 15-20 ft-lbs. When inserting or removing the wrench from

the sprinkler/cup assembly care should be taken to prevent

damage to the sprinkler. DO NOT WRENCH ON ANY OTHER

PART OF THE SPRINKLER/CUP ASSEMBLY.

Maintenance

The Model F4FR-NF should be inspected quarterly and

the sprinkler system maintained in accordance with NFPA

25. Do not clean sprinklers with soap and water, ammonia

or any other cleaning fluids. Remove any sprinkler that has

been painted ( other than factory applied) or damaged in

any way. A stock of spare sprinklers should be maintained

to allow quick replacement of damaged or operated sprin-

klers. Prior to installation, sprinklers should be maintained in

the original cartons and packaging to minimize the potential

for damage to sprinklers that would cause improper opera-

tion or non-operation.

Engineering Specification

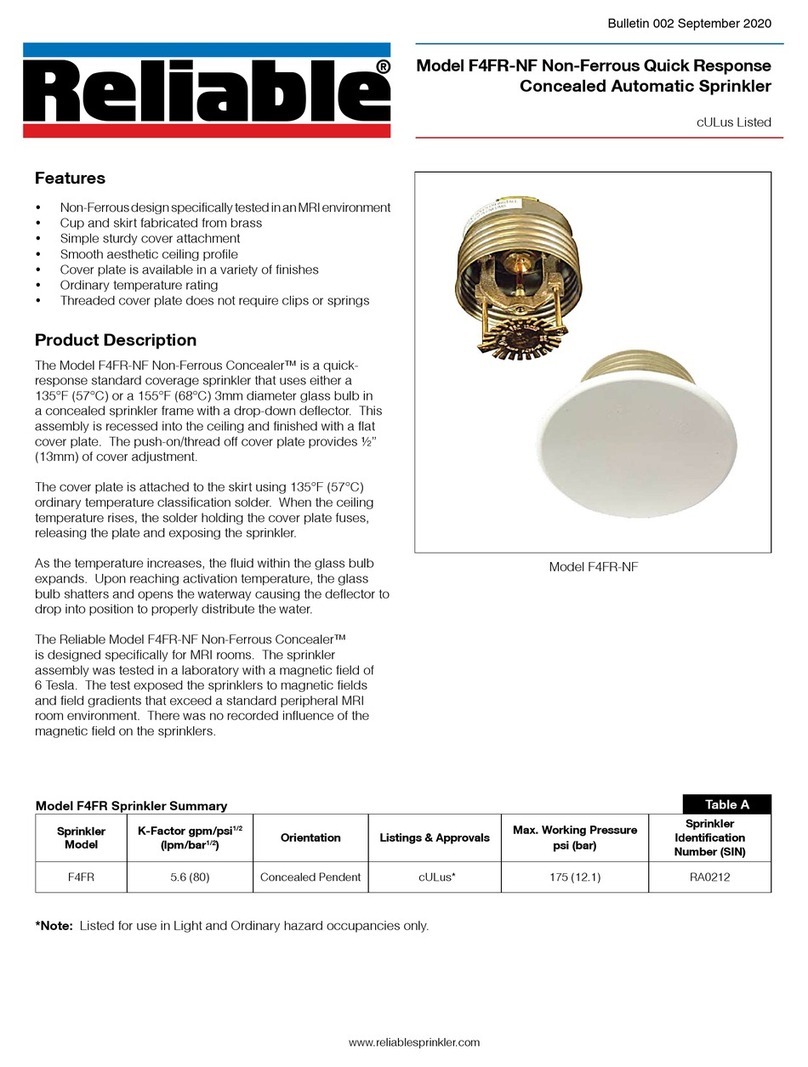

Sprinklers shall be cULus Listed, non-ferrous, quick re-

sponse concealed pendent sprinklers specifically designed

and tested for use in MRI type applications, and able to with-

stand exposure to a magnetic field of up to 6 Tesla. The con-

cealed sprinkler frame and cover plate assembly shall be of

all brass construction, including the drop-down deflector

and sprinkler cup assembly. The water seal shall consist of

a Teflon film coated Belleville spring washer and bulb/ma-

chined cup assembly utilizing a 3 mm glass bulb thermal el-

ement. Concealed sprinklers shall have a ½” NPT with a

nominal K-factor of 5.6 (80.0). Temperature rating of both

The equipment presented in this bulletin is to be installed in accordance with the latest pertinent Standards of the National Fire Protection Association, Factory Mutual Research

Corporation, or other similar organizations and also with the provisions of governmental codes or ordinances whenever applicable.

Products manufactured and distributed by Reliable have been protecting life and property for over 80 years, and are installed and serviced by the most highly qualified and reputa-

ble sprinkler contractors located throughout the United States, Canada and foreign countries.

The Reliable Automatic Sprinkler Co., Inc.

(800) 431-1588 Sales Offices

(800) 848-6051 Sales Fax

(914) 829-2042 Corporate Offices

www.reliablesprinkler.com Internet Address

Manufactured by

Ordering Information

Specify

1. Sprinkler Model

2. Cover Plate Finish

12

²NPT (R12) inlet - Figure 1

Installation Wrench

Model G4 Sprinkler Wrench

Revision lines indicate updated or new data.

E.G. Printed in U.S.A. 9/06 P/N 9999970241

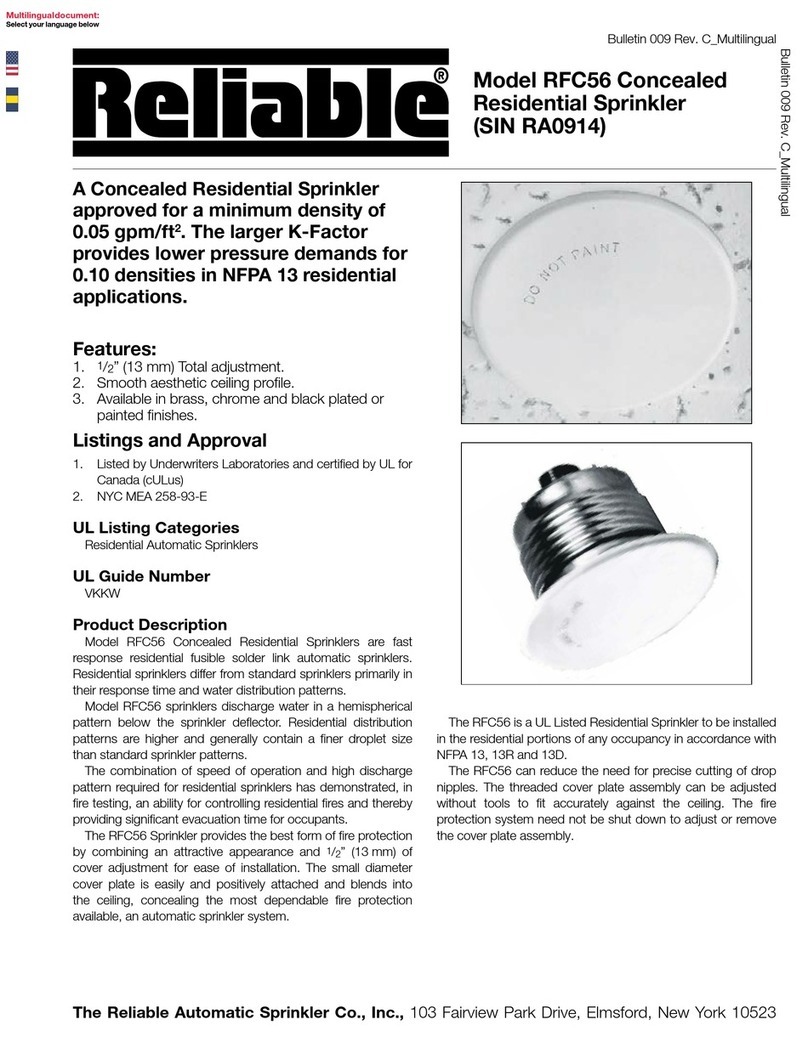

Classification Sprinkler Cover Plate

Max. Ceiling

Temp.

Ordinary 135°F/57°C

155°F/68°C135°/57°C 100°F/38°C

Temperatures Ratings

Installation Data

Total

Adjustment

Nominal

Orifice

Nominal

K Factor

Thread Approval

Sprinkler

Identification

Number (SIN)US Metric

12²(13mm) 12²(15mm) 5.6 80 12²NPT (R½) cULus RA0212

(1) Other colors and finishes are

available. Consult factory for details.

Note: Paint or any other

coatings applied over the

factory finish will void all

approvals and warranties.

Standard Finishes:

Bronze

Bright Brass Plated

Chrome Plated

Black Plated

White

(1):

Recycled

Paper

the sprinkler and the cover plate shall be 135 °F(57°C).

Sprinkler cover plate shall be capable of providing ½” of ad-

justment and shall attach to the sprinkler cup by a strong

threaded engagement. The sprinkler cup shall be rein-

forced with an attached brass wrenching plate to protect the

sprinkler cup from damage during installation. Concealed

sprinklers shall be UL Listed for Light Hazard and Ordinary

Hazard occupancies. Standard cover finish to be: [Bronze]

[Chrome Plated] [White] [Bright Brass Plated] [Black Plated]

[Specialty – specify]. Quick Response Concealed Pendent

Sprinklers shall be the Reliable Non-Ferrous Concealer,

Model F4FR-NF, SIN RA0212.