valve, the strainer shall be located at the outlet of the

retarding chamber unless the retarding chamber is

provided with an approved integral strainer in its outlet.

The piping to the mechanical alarm should be pitched

to allow proper drainage back through the strainer.

Alarm, dry pipe and deluge valve trimmings provide

the proper drain outlet. Refer to respective valve

bulletins for installation of trimmings.

The 1″(25mm) drain outlet should discharge into an

open drain.

No single mechanical alarm should be connected to

more than three sprinkler systems and they should be

located in the same fire area. A ¾ ″NPT (R¾) swing

check valve must be located in each alarm line near the

junction(s) going to the Mechanical Alarm. This will

assure that water flowing from the alarm port of the

opened Valve will go directly to the water motor. A hole

approximately 18″(3.2mm) diameter should be drilled

through the clapper of each check valve near the center.

Operation

When an alarm (wet), dry pipe or deluge valve is

operated due to fire, water flows through the ¾ ″(20mm)

strainer, and ¾ ″(20mm) piping that connects the

mechanical sprinkler alarm to the valve. On entering the

mechanical sprinkler alarm inlet, the water passes

through the nozzle and impinges against the gong

producing a continuous piercing alarm. The water, after

impinging against the pelton wheel, drains through the 1″

(25mm) drain outlet in the body housing.

The alarm continues to sound as long as water is

flowing through the sprinkler system. It may be shut off

by closing the alarm control valve located in the alarm line

connecting the mechanical sprinkler alarm with the alarm

(wet), dry pipe or deluge valve. Normally, the alarm

control valve must be sealed in the open position.

The Model C Mechanical Sprinkler Alarm is self setting

after each operation, eliminating the need of removing

cover plates, etc. to reset internal mechanisms.

Installation Instructions

The Model C Mechanical Sprinkler Alarm shall be

located as near the alarm (wet), dry or deluge valve as

practicable in order to avoid long runs or many fittings in

the piping. The total length of the pipe should not exceed

75 feet ( 22.9m ) nor shall the mechanical sprinkler alarm

be located over 20 feet (6.1m) above the valve. If

absolutely necessary to exceed 75 feet (22.9 m), the pipe

line to the mechanical sprinkler alarm shall be increased

one or more sizes to compensate for loss of pressure due

to hydraulic friction.

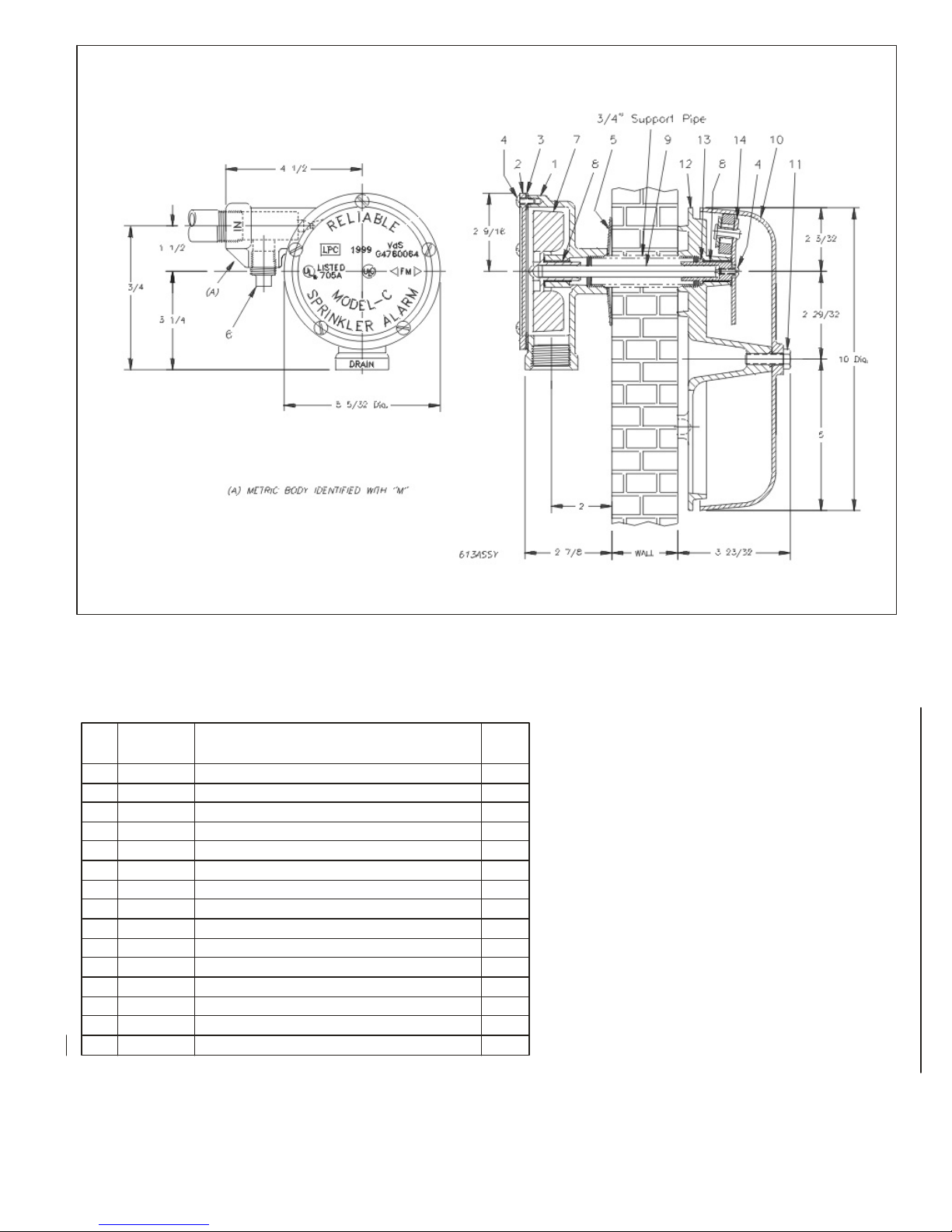

1. Locate and cut hole in building wall for connecting ¾″

(20mm) support pipe of appropriate length wall

thickness plus 1″(25mm).

2. Assemble the support pipe to the Wall Plate

(95106603) without removing the Gong (93806612)

and position this assembly on the outside wall with the

support pipe through the wall.

3. Remove the Body Cover (92106603), Cover Gasket

(93706602), and Pelton Wheel (97006603) from the

Body (91006603).

4. Place the Wall Support Washer (96906603) over the

support pipe as shown in the assembly drawing and

screw the Body onto the support pipe until the entire

assembly is aligned and secure to the wall.

5. Slip the Drive Shaft (96206603) thru the support pipe

and into the Drive Shaft Adapter (90086601). Rotate

the drive shaft to make sure it’s properly inserted (the

gong will alarm). Mark and cut the drive shaft where it

projects from the hub in the body.

6. With the drive shaft in place, make sure the Nylon

Bearing (90506603) is in the hub and insert the Pelton

Wheel through this onto the drive shaft. Spin the

Pelton Wheel to ensure that the assembly is free and

that the gong alarms.

7. Replace the Body Cover and Cover Gasket.

8. Connect alarm inlet to the alarm (wet), dry pipe or

deluge valve using galvanized or brass pipe of size

not less than ¾ ″ (20mm). An approved ¾ ″(20mm)

strainer is included for installation near the alarm outlet

of the alarm (wet), dry pipe or deluge valve. When a

retarding chamber is used in connection with an alarm

2.