R12UZ0037EU0101 Rev.1.02 Page 4 of 36

Feb 15, 2019

ISL8212MEVAL1Z 2. Functional Description

2. Functional Description

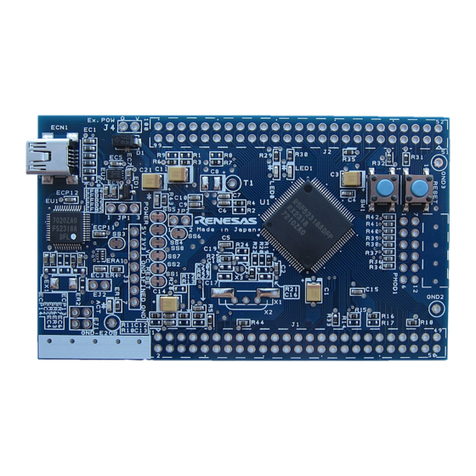

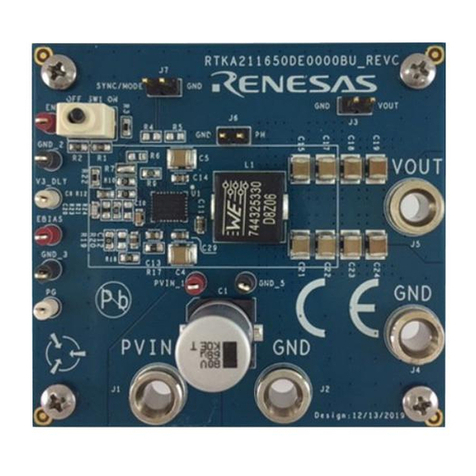

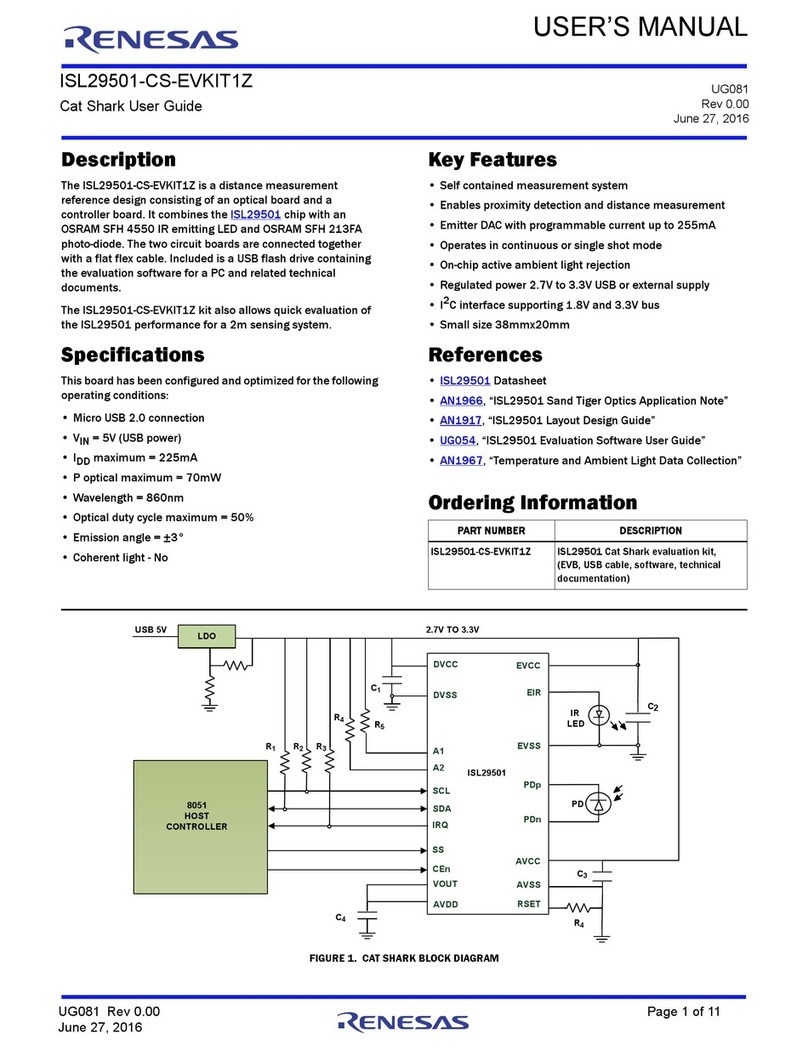

The ISL8212MEVAL1Z evaluation board provides the peripheral circuitry to evaluate the ISL8212M feature set. The

ISL8212MEVAL1Z includes several connectors, test points, and external pin-strap resistors that simplify ISL8212M

validation. Figure 4 on page 23 shows the top of the ISL8212MEVAL1Z. Figure 5 on page 23 shows the bottom of the

ISL8212MEVAL1Z.

2.1 Quick Start Guide

(1) Disable the module by toggling the mechanical switch SW1 to 2-3 as shown in Figure 4.

(2) Connect the DC input power supply to banana sockets J4 and J3 and the electronic load to sockets J14 and J15.

Ensure that the polarity for the power leads is correct and the input voltage is within the ISL8212MEVAL1Z’s

operating range of 4.5V to 15V. Use test points TP1 (VIN) and TP3 (GND) to accurately measure the input

voltage.

(3) Toggle the mechanical switch SW1 to 1-2 to enable the module.

(4) Turn on the DC input power supply.

(5) Probe test points TP3 (VOUT) and TP4 (PGND) to observe the output voltage. The output voltage should read

1V.

(6) Adjust the input voltage, VIN, within the specified range and observe the output voltage. The output voltage

variation should be within ±1.5%.

(7) Adjust the load current to within the specified range of 0A to 15A and observe the output voltage. The output

voltage variation should be within ±1.5%.

(8) To change VOUT, disconnect the ISL8212MEVAL1Z from the setup and populate 1% standard 0402 resistors

at the R2 and R3 placeholder locations on the bottom layer. Use Table 1 on page 5 as a reference for

programming different output voltages. See the “ISL8212M Design Guide Matrix of Typical Applications”

table in the ISL8212M datasheet for recommended values in typical applications.

(9) To change PFM/PWM mode and TCOMP, disconnect the ISL8212MEVAL1Z from the setup and populate

1% standard 0402 resistors at the R10 and R11 placeholder locations on the bottom layer. Use Table 2 on

page 10 as a reference for customizing module specifications. Renesas recommends using +5°C as the

TCOMP.

(10) To change OCP retry/latchoff, fSW

, AV gain and ultrasonic PFM enable, disconnect the ISL8212MEVAL1Z

from the setup and populate 1% standard 0402 resistors at the R8 and R9 placeholder locations on the bottom

layer. Use Table 3 on page 17 as a reference for customizing module specifications. See the “ISL8212M

Design Guide Matrix of Typical Applications” table in the ISL8212M datasheet for recommended values in

typical applications.

(11) To change the soft-start ramp rate, RR, and AV gain multiplier, disconnect the ISL8212MEVAL1Z from the

setup and populate 1% standard 0402 resistors at the R5 and R6 placeholder locations on the bottom layer. Use

Table 4 on page 20 as a reference for customizing module specifications. See the “ISL8212M Design Guide

Matrix of Typical Applications” table in the ISL8212M datasheet for recommended values in typical

applications.

2.2 Thermal Considerations and Current Derating

Proper board layout is critical so that the module can operate safely and deliver the maximum allowable power. For

the board to operate properly at high ambient temperature environments and carry full load current, carefully

design the board layout to maximize thermal performance. For best thermal performance, use enough trace width,

copper weight, and proper connectors.

The ISL8212MEVAL1Z is capable of operating at 15A full load current at room temperature without the need for

additional cooling systems. However, if the ISL8212MEVAL1Z needs to operate at elevated ambient temperatures,

the available output current needs to be derated. See the derated current curves in the ISL8212M datasheet to

determine the maximum output current that the ISL8212MEVAL1Z can supply.