5

Table of contents

1Introduction.......................................................................................................... 6

1.1 Function ...........................................................................................................................6

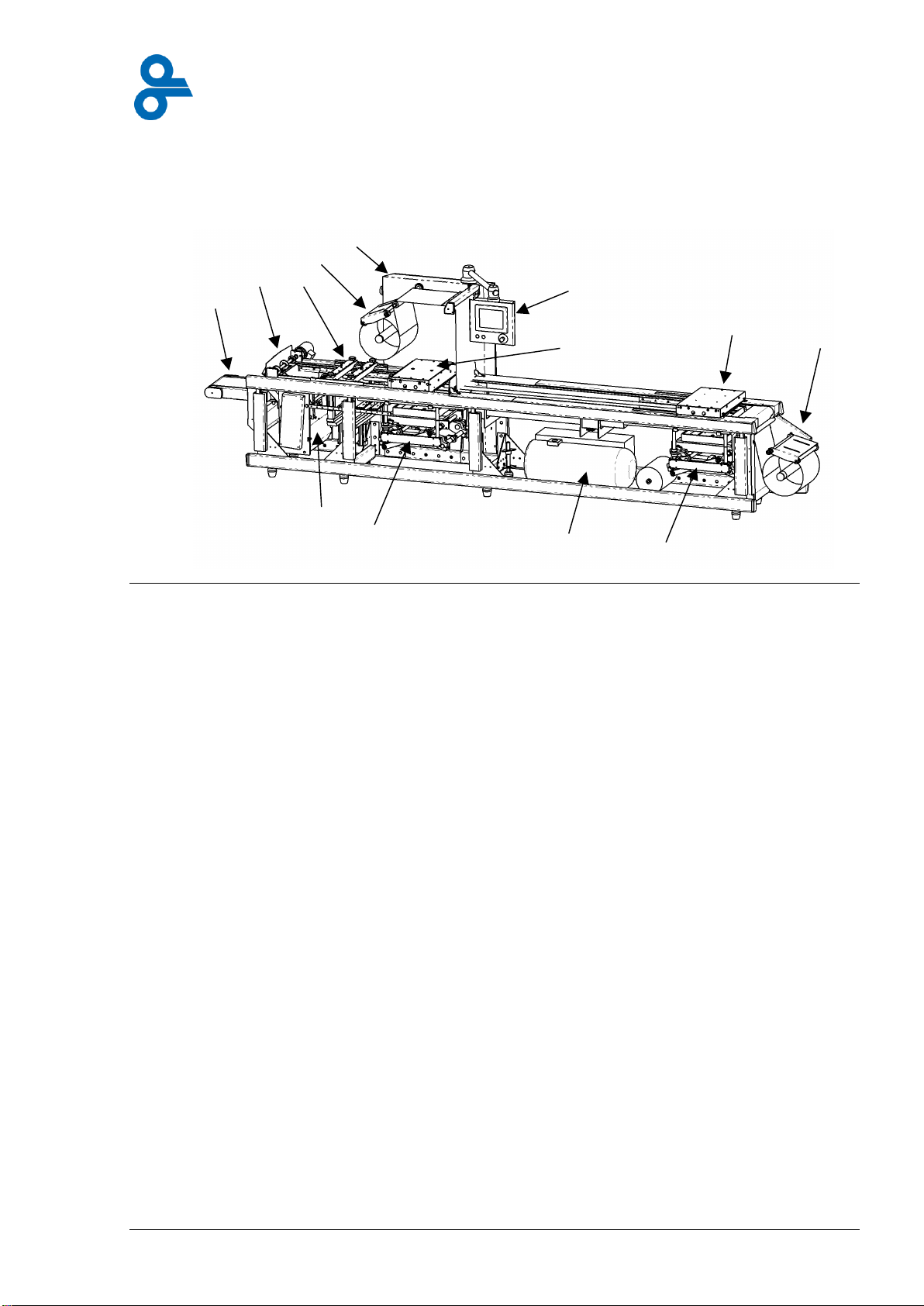

1.2 Most important parts ........................................................................................................7

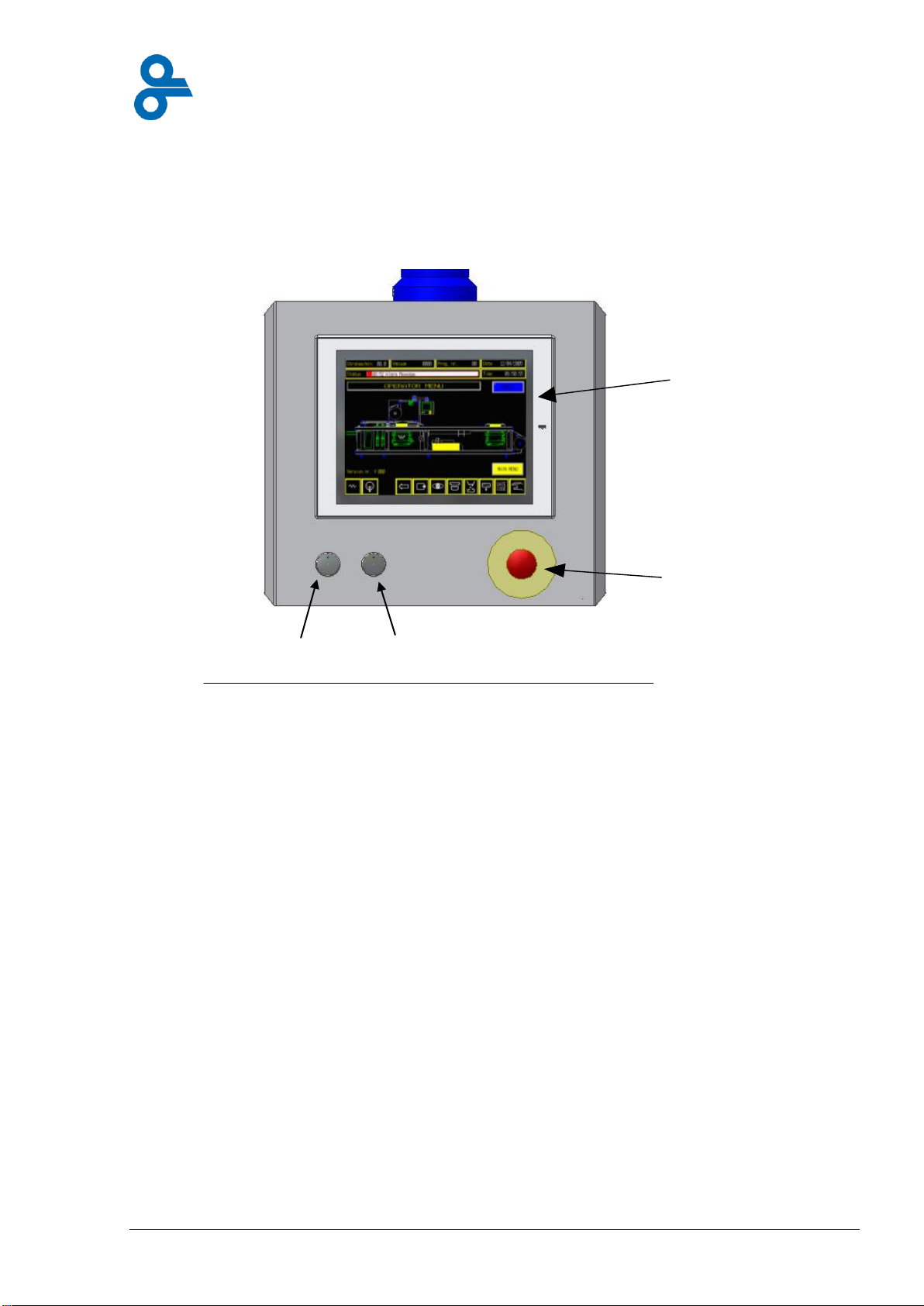

1.3 Control equipment............................................................................................................8

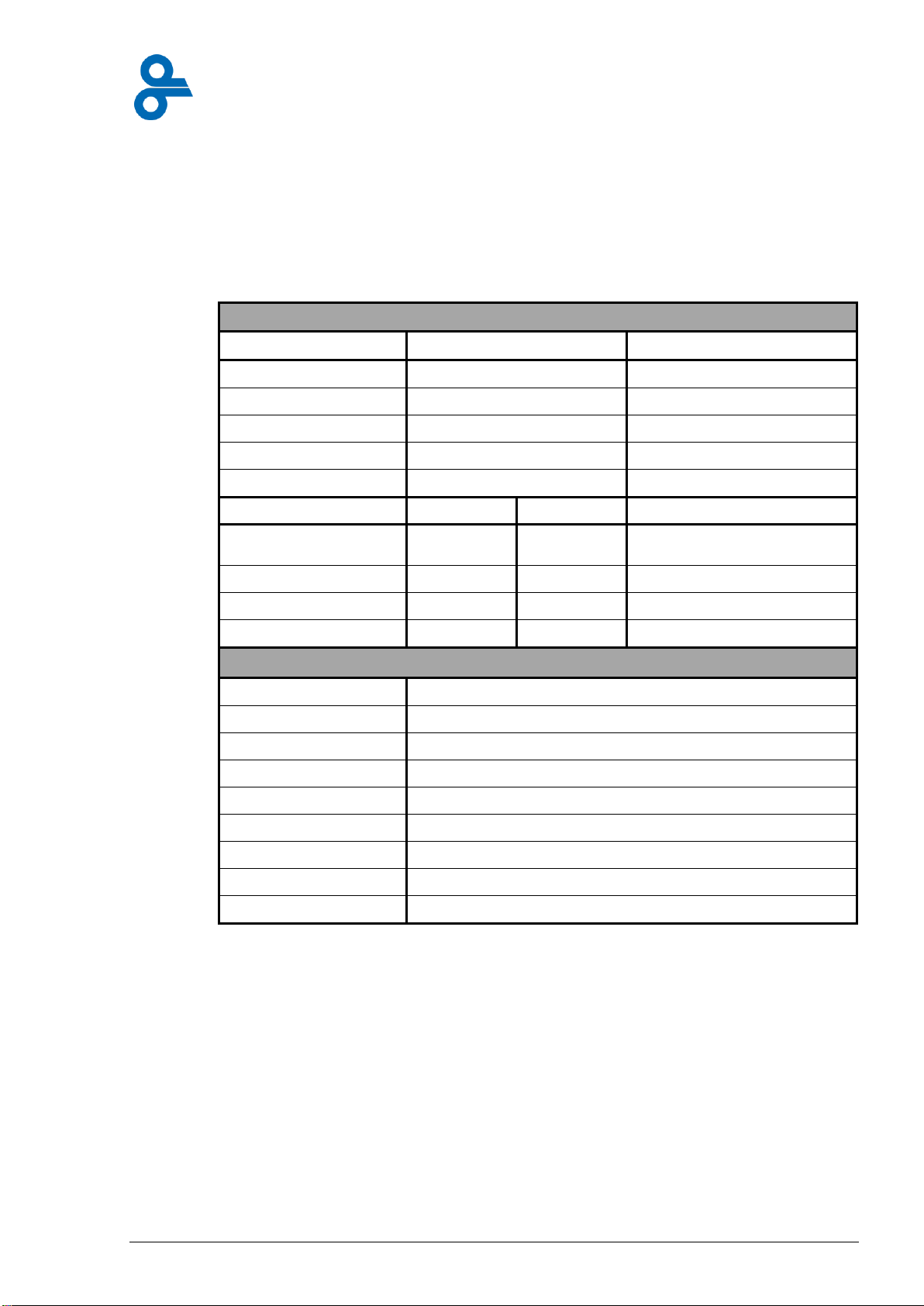

1.4 Technical specifications...................................................................................................9

2Preventive measures and safety instructions.................................................. 13

2.1 General safety instructions ............................................................................................13

2.2 Intended use and use not recommended ......................................................................15

2.3 Meaning of the symbols.................................................................................................16

2.4 Safety systems...............................................................................................................19

2.5 Transportation................................................................................................................23

3Description of the machine ............................................................................... 26

3.1 Operation .......................................................................................................................26

3.2 Description of machine frame ........................................................................................27

3.3 Description of bottom film unwind unit...........................................................................28

3.4 Description of forming station ........................................................................................32

3.5 Description of loading area ............................................................................................34

3.6 Top film unwinding unit ..................................................................................................38

3.7 Photocell and film brake.................................................................................................38

3.8 Description of sealing station.........................................................................................42

3.9 Cross cutting ..................................................................................................................43

3.10 Complete-cut punch (only available for RE25!) .............................................................48

3.11 Longitudinal cutters........................................................................................................49

3.12 Discharge conveyor belt.................................................................................................53

3.13 Control cabinet...............................................................................................................54

3.14 Drive gear.......................................................................................................................55

3.15 Film edge trim removal...................................................................................................56

4Control panel...................................................................................................... 59

4.1 How the touch screen works..........................................................................................59

4.2Machine operating menus..............................................................................................61

4.3 Operator menu...............................................................................................................65

4.4 Main menu .....................................................................................................................75

4.5 Access code.................................................................................................................101

5Operating the machine .................................................................................... 103

5.1 Preventive measures and safety instructions ..............................................................103

5.2 Turning on the machine ...............................................................................................106

5.3 Fitting the rolls of film...................................................................................................112

5.4 Setting the photocell.....................................................................................................115

5.5 Calibrate the photocell .................................................................................................116

5.6 Turning the machine off ...............................................................................................117

5.7 Operating the machine while it is running....................................................................117

5.8 Energy-saving operation..............................................................................................118

6Cleaning and maintenance.............................................................................. 120

6.1 Guidelines and methods ..............................................................................................120

6.2 Maintenance procedures..............................................................................................121

6.3 Maintenance instructions .............................................................................................126

6.4 Recording the maintenance and cleaning logbook......................................................134

7Overview of status lines .................................................................................. 136

7.1 Environmental factors ..................................................................................................136

7.2 Overview of status lines...............................................................................................137

7.3Defects affecting the film..............................................................................................139

8Explanatory list of words................................................................................. 140

9Appendix........................................................................................................... 144