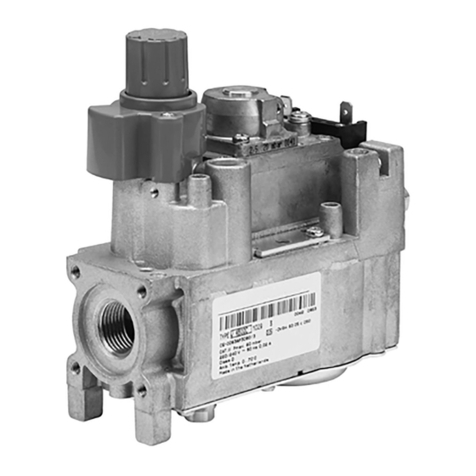

VR8300 CONTINUOUS PILOT COMBINATION GAS CONTROL

69-0668—05 8

MAINTENANCE

Fire or Explosion Hazard.

Can cause property damage, severe injury, or

death.

Improper cleaning or reassembly can cause gas

leakage. When cleaning, ensure that control is

reassembled properly and perform gas leak test.

Regular preventive maintenance is important in

applications that place a heavy load on system controls

such as in the commercial cooking and agricultural and

industrial industries because:

• In many such applications, particularly commercial

cooking, the equipment operates 100,000-200,000

cycles per year. Such heavy cycling can wear out the

gas control in one to two years.

• Exposure to water, dirt, chemicals and heat can

damage the gas control and shut down the control

system.

The maintenance program should include regular check-

out of the gas control as outlined in the Startup and

Checkout section, and the control system as described in

the appliance manufacturer literature.

Maintenance frequency must be determined individually

for each application. Some considerations are:

• Cycling frequency. Appliances that may cycle 100,000

times annually should be checked monthly.

• Intermittent use. Appliances that are used seasonally

should be checked before shutdown and again before

the next use.

• Consequence of unexpected shutdown. Where the

unexpected shutdown is costly, the system should be

checked more often.

• Dusty, wet, or corrosive environment. In these

environments the gas control can deteriorate more

rapidly so the system should be checked more often.

The gas control should be replaced if:

• It does not perform properly on checkout or trouble-

shooting.

• The gas control knob is hard to turn or push down, or

it fails to pop up when released.

• The gas control is likely to have operated for more

than 200,000 cycles.

SERVICE

Fire or Explosion Hazard.

Can cause property damage, severe injury or

death

Do not disassemble the gas control; it contains

no replaceable components. Attempted

disassembly or repair can damage the gas

control.

Hazardous voltage.

Improper installation can burn out thermostat

heat anticipator.

Do not apply a jumper across or short the valve

coil terminals.

IMPORTANT

Allow 60 seconds after shutdown before re-

energizing step-opening model to ensure light

off at step pressure.

If Pilot Burner Flame does not Light:

1. Make sure that the main gas supply valve is open

and the pilot gas supply line is purged of air.

2. Light the pilot burner flame following procedures in

Light the Pilot Burner Flame section. If pilot burner

flame does not light:

a. Check the pilot gas adjustment screw. If closed,

readjust the pilot flame. Refer to Adjust the

Pilot Burner Flame section.

b. Perform the Gas Leak Test at the compression

fitting. If a gas leak is detected, replace the old

compression fitting or tighten the newly

installed one. See Fig. 1.

c. Make sure that the pilot burner tubing or pilot

burner orifice is not clogged.

If Pilot Burner Flame Goes Out when

Gas Control Knob is Released:

1. Make sure the gas control knob is held in at least

one minute to allow the thermocouple time to heat.

2. Check the pilot burner flame adjustment. Refer to

Adjust the Pilot Burner Flame section.

3. Check the wiring between the thermocouple and

the gas control valve operator.

4. Make sure that the thermocouple connection to the

power unit is tightened 1/4 turn beyond finger

tight.

5. If pilot burner flame goes out, measure the open-

circuit thermocouple output voltage. Compare it to

the acceptable range charts in the thermocouple

specifications or in the Gas Controls Handbook.

Replace the thermocouple if voltages are outside

the acceptable range.

6. Check the power unit resistance. If it is above

11 ohms, replace the gas control.

If Main Burner does not Come on

with Call For Heat:

1. Make sure the gas control knob is in the ON posi-

tion.

2. Adjust the thermostat several degrees above the

room temperature.

3. Use an ac voltmeter to measure the voltage across

terminals TH and TR. If:

a. No voltage is present, check the control circuit

for proper operation.

b. 24 Vac is present, but first operator did not

click open, check for excessive inlet gas pres-

sure. If inlet gas pressure is correct, replace the

gas control.

4. Measure the closed thermocouple output voltages

and compare to the acceptable range charts in the

thermocouple specifications or in the Gas Controls

Handbook. Replace the thermocouple if voltages

are outside the acceptable range.

If Main Burner is Over firing:

Adjust the gas control pressure regulator to the correct

pressure. If the regulator cannot be adjusted and supply

pressure is in the normal range, replace the gas control.