SV9541, SV9641 SMARTVALVE™ SYSTEM CONTROLS

369-2012—01

High Humidity or Dripping Water

Dripping water can cause the control to fail. Never install

an appliance where water can drip on the control. In

addition, high ambient humidity can cause the control to

corrode and fail. If the appliance is in a humid

atmosphere, make sure air circulation around the control

is adequate to prevent condensation. Also, regularly

check out the system.

Corrosive Chemicals

Corrosive chemicals can attack the control, eventually

causing a failure. If chemicals are used for routine

cleaning, avoid contact with the control. Where

chemicals are suspended in air, as in some industrial or

agricultural applications, protect the control with an

enclosure.

Dust or Grease Accumulation

Heavy accumulations of dust or grease can cause the

control to malfunction. Where dust or grease can be a

problem, provide covers for the control to limit

contamination.

Heat

Excessively high temperatures can damage the control.

Make sure the maximum ambient temperature at the

control does not exceed the rating of the control. If the

appliance operates at very high temperatures, use

insulation, shielding, and air circulation, as necessary, to

protect the control. Proper insulation or shielding should

be provided by the appliance manufacturer; verify proper

air circulation is maintained when the appliance is

installed.

INSTALLATION

When Installing this Product…

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a

hazardous condition.

2. Check the ratings given in the instructions and on

the product to make sure the product is suitable for

your application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out product

operation as provided in these instructions.

Fire or Explosion Hazard.

Can cause property damage, severe injury or

death.

Follow these warnings exactly:

1. Disconnect power supply before wiring to

prevent electrical shock or equipment damage.

2. To avoid dangerous accumulation of fuel gas,

turn off the gas supply at the appliance service

valve before starting installation, and perform

Gas Leak Test after installation is complete.

3. Do not bend pilot tubing at ignition system

control or pilot burner after compression fitting

is tightened, or gas leakage at the connection

can result.

4. Always install a sediment trap in the gas

supply line to prevent contamination of the

ignition system control.

Electrical Shock or Equipment Damage Hazard.

Can shock individuals or short equipment

circuitry.

1. Disconnect power supply before installation.

2. Never apply a jumper across or short any of the

terminals in the SV9541 or SV9641 wiring

harness. This can damage the system

transformer or the control.

Follow the appliance manufacturer instructions, if

available; otherwise, use these instructions as a guide.

IMPORTANT

These ignition system controls are shipped with

protective seals over the inlet and outlet

tappings. Do not remove the seals until ready to

install adapters or connect the piping.

Converting Ignition System Control

from Natural Gas to LP Gas (or LP

Gas to Natural Gas)

Fire or Explosion Hazard.

Can cause property damage, severe injury, or

death.

1. Do not attempt to convert step-opening

models (suffix letter P).

2. Always change the main and pilot burner

orifices when converting from natural to LP

gas or from LP to natural gas. Carefully follow

appliance manufacturer specifications and

instructions to assure proper appliance

conversion.

3. Ignition system controls are factory-set for

natural (and manufactured) or LP gas. Do not

attempt to use an ignition system control set

for natural (manufactured) gas on LP gas, or an

ignition system control set for LP gas on

natural (manufactured) gas.

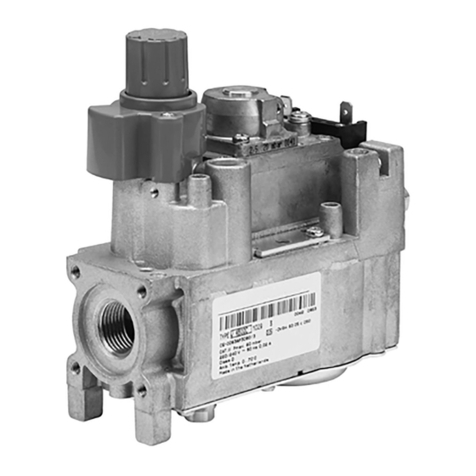

Ignition system controls with standard, slow-opening,

and two-stage regulators (model numbers with suffix H,

K, M, or Q) can be converted from one gas to the other

with a conversion kit (ordered separately). See Table 4 to

select the appropriate conversion kit.

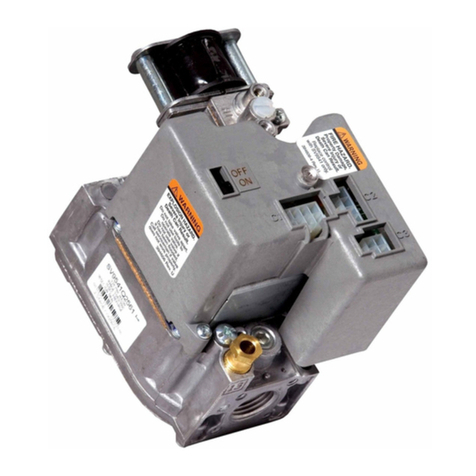

Install Adapters To Control

If adapters are being installed on the control, mount them

as follows:

Flanges

1. Choose the appropriate flange for your application.

2. Remove the seal over the ignition system control

inlet or outlet.

3. Make sure that the O-ring is fitted in the groove of

the flange. If the O-ring is not attached or is

missing, do not use the flange.

4. With the O-ring facing the ignition system control,

align the screw holes on the ignition system

control with the holes in the flange. Insert and

tighten the screws provided with the flange. See

Fig. 1. Tighten the screws to 25 inch-pounds of

torque to provide a gas-tight seal.