SMARTVALVE™ SYSTEM CONTROLS

69-1059—01 4

FIRE OR EXPLOSION HAZARD CAN CAUSE

PROPERTY DAMAGE, SEVERE INJURY OR DEATH

Follow these warnings exactly:

1. Disconnect power supply before wiring to

prevent electrical shock or equipment damage.

2. To avoid dangerous accumulation of fuel gas,

turn off gas supply at the appliance service

valve before starting installation, and perform

Gas Leak Test after completion of installation.

3. Do not bend pilot tubing at ignition system

control or pilot burner after compression fitting

is tightened, or gas leakage at the connection

can result.

4. Always install a sediment trap in gas supply

line to prevent contamination of ignition

system control.

LINE VOLTAGE CAN CAUSE PROPERTY DAMAGE,

SEVERE INJURY OR DEATH.

Never apply a jumper across or short any of the

terminals in the SV9540; SV9640 wiring harness.

This can damage the system transformer or the

control.

Follow the appliance manufacturer instructions if

available; otherwise, use these instructions as a guide.

Converting Ignition System Control from

Natural Gas to LP Gas Application (or LP

Gas to Natural Gas Application)

FIRE OR EXPLOSION HAZARD CAN CAUSE

PROPERTY DAMAGE, SEVERE INJURY OR DEATH

Do NOT attempt to convert step-opening models

(SV9540P/SV9542P; SV9640P/SV9642P).

Always change the main and pilot burner orifices

when converting from natural to LP gas or from

LP to natural gas. Follow appliance manufacturer

specifications and instructions carefully to

assure proper appliance conversion.

Ignition system controls are factory-set for natural (and

manufactured) or LP gas. Do not attempt to use an

ignition system control set for natural (manufactured)

gas on LP gas, or an ignition system control set for LP

gas on natural (manufactured) gas.

Ignition system controls with standard or slow opening

regulators (SV9540M,H; SV9640M,H) can be converted

from one gas to the other with a conversion kit (ordered

separately). Order part no. 393691 to convert from

natural (manufactured) to LP gas; order part no. 394588

to convert from LP to natural (manufactured) gas.

IMPORTANT

Ignition system controls with step-opening

regulators (SV9540P; SV9640P) CANNOT be

field-converted to LP or natural gas.

Install Adapters To Control

If adapters are being installed on the control, mount them

as follows:

Flanges

1. Choose the appropriate flange for your application.

2. Remove the seal over the ignition system control

inlet or outlet.

3. Make sure that the O-ring is fitted in the groove of

the flange. If the O-ring is not attached or missing,

do not use the flange.

4. With the O-ring facing the ignition system control,

align the screw holes on the ignition system con-

trol with the holes in the flange. Insert and tighten

the screws provided with the flange. See Fig. 1.

Tighten the screws to 25 inch-pounds of torque to

provide a gas-tight seal.

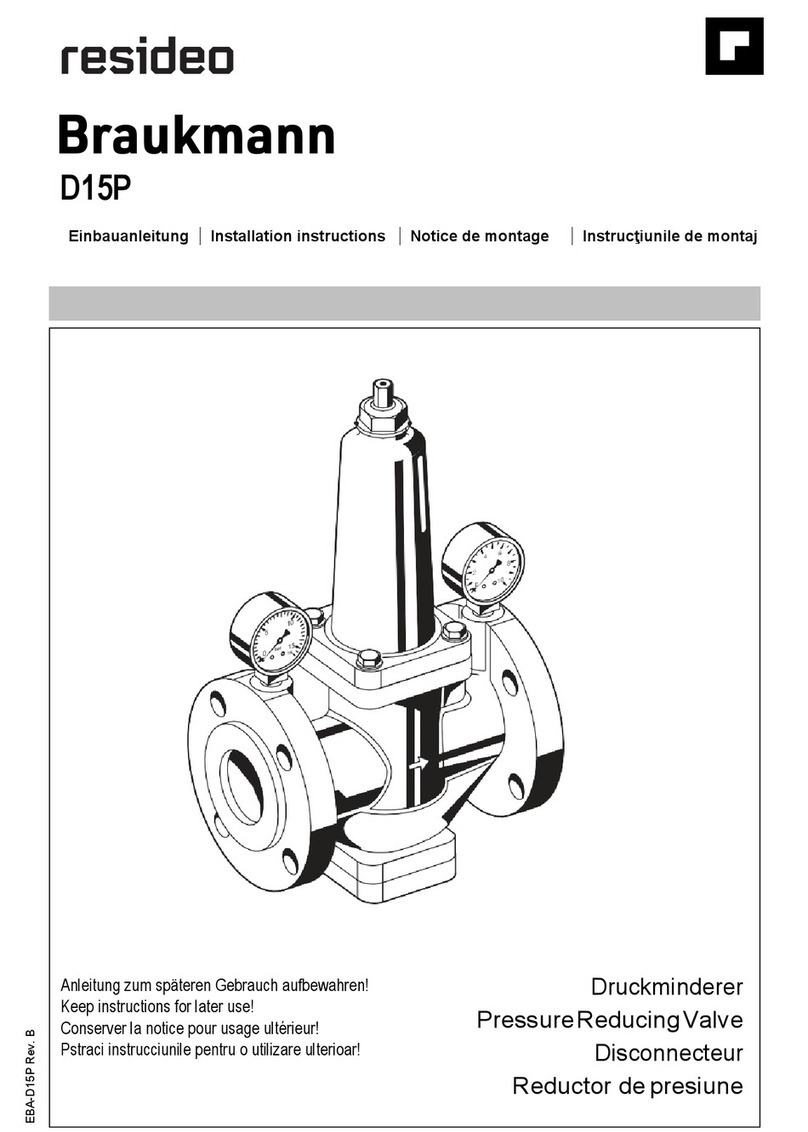

Fig. 1. Firmly fasten flange to valve, but do not

overtighten screws.

Bushings

1. Remove the seal over the ignition system control

inlet or outlet.

2. Apply a moderate amount of good quality pipe

compound to the bushing, leaving two end threads

bare. On an LP installation, use compound resis-

tant to LP gas. Do not use Teflon tape.

3. Insert the bushing in the ignition system control

and carefully thread the pipe into the bushing until

tight.

Complete the instructions below for installing the piping,

installing the control, connecting the pilot tubing and

wiring. Make sure the leak test you perform on the

control after completing the installation includes leak

testing the adapters and screws. If you use a wrench on

the valve after the flanges are installed, use the wrench

only on the flange, not on the control. See Fig. 5.

Location

The SV9540; SV9640 are mounted in the appliance

vestibule on the gas manifold.

IMPORTANT

These ignition system controls are shipped with

protective seals over the inlet and outlet tap-

pings. Do not remove the seals until ready to

connect the piping.

M12168

VALVE OUTLET

FLANGE

9/64 INCH

HEX

SCREWS

(4)

1

1 DO NOT USE FLANGES ON 3/4 IN. INLET

AND 3/4 IN. OUTLET MODELS, AND ON

THE 3/4 IN. OUTLET SIDE OF 1/2 IN.

INLET AND 3/4 IN. OUTLET MODELS.