Yamato SK 100C User manual

Other Yamato Laboratory Equipment manuals

Yamato

Yamato DF411 User manual

Yamato

Yamato BM Series User manual

Yamato

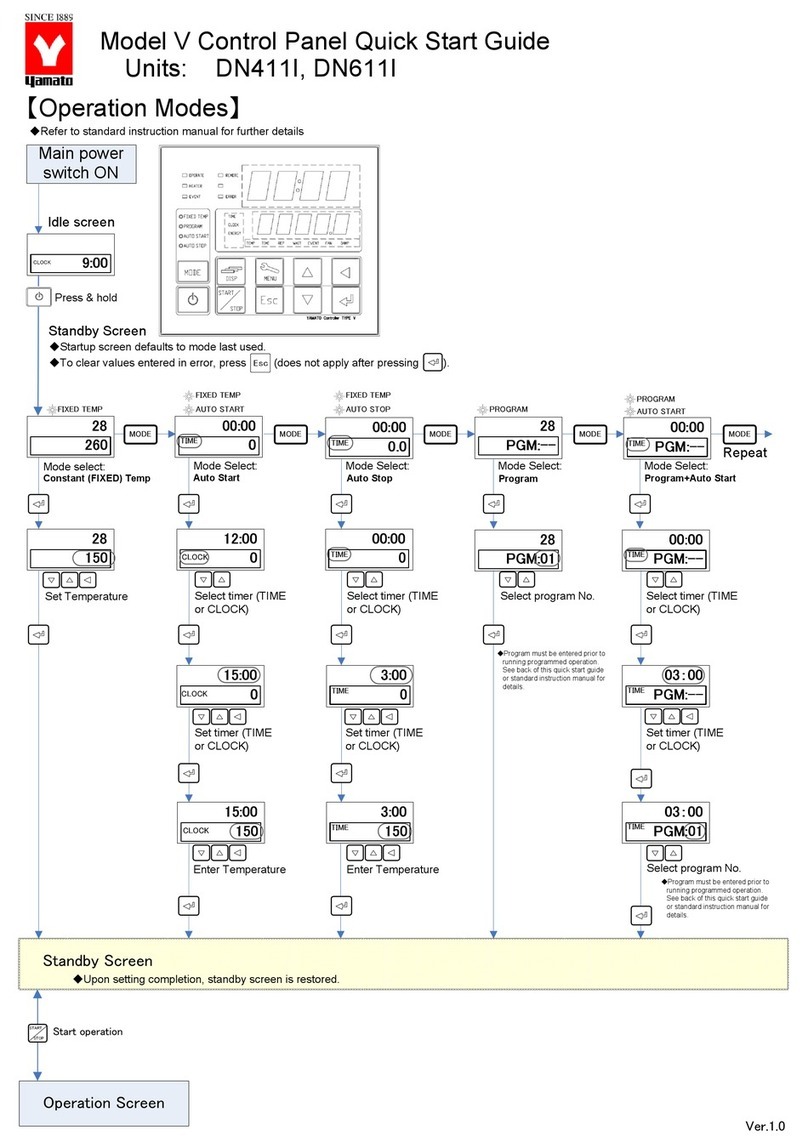

Yamato DN411I User manual

Yamato

Yamato DP23C User manual

Yamato

Yamato Fish Analyzer PRO DFA110 User manual

Yamato

Yamato BA300 User manual

Yamato

Yamato DF410 User manual

Yamato

Yamato IL603 User manual

Yamato

Yamato SK101C User manual

Yamato

Yamato BK300 User manual

Yamato

Yamato SM201 User manual

Yamato

Yamato IL702 User manual

Yamato

Yamato NeoCool Circulator CF301 User manual

Yamato

Yamato CA300 User manual

Yamato

Yamato BS 200 User manual

Yamato

Yamato RT200 User manual

Yamato

Yamato SM520 User manual

Yamato

Yamato MK161 User manual

Yamato

Yamato IC103CW User manual

Yamato

Yamato SK102C User manual

Popular Laboratory Equipment manuals by other brands

Agilent Technologies

Agilent Technologies 5800 ICP-OES user guide

Endress+Hauser

Endress+Hauser Cleanfit CPA875 operating instructions

NI

NI PXI-5422 CALIBRATION PROCEDURE

Collomix

Collomix Aqix operating instructions

SPEX SamplePrep

SPEX SamplePrep 6875 Freezer/Mill Series operating manual

Ocean Insight

Ocean Insight FLAME-NIR+ Installation and operation manual

Parker

Parker ALIGN-MG-NA Installation, operation and maintenance manual

BD

BD 644787 user guide

DENTAURUM

DENTAURUM Compact Megaplus Instructions for use

Biuged Laboratory Instruments

Biuged Laboratory Instruments BGD 626 instruction manual

VWR

VWR SAS Super IAQ instruction manual

illumina

illumina MiSeqDx reference guide