1

INSTALLATION INSTRUCTIONS

RHEEM FLUE TERMINAL DIVERTER

WITH HEAT SHIELD (PN 299287)

RHEEM EXTENDED FLUE TERMINAL DIVERTER

WITH HEAT SHIELD (PN 299285)

This instruction details the installation of the Rheem Flue Terminal Diverter with Heat Shield (PN 299287) and

the Rheem Extended Flue Terminal Diverter with Heat Shield (PN 299285) to the Rheem Electronic

Continuous Flow Gas water heater models noted below (refer to the rating plate for model number):

874826NF, 874T26NF (26L/min 60°C, Natural Gas, Frost Protected)

876826NF, 876T26NF (26L/min 50°C, Natural Gas, Frost Protected)

Warning: Fitting of a Flue Terminal Diverter or Extended Flue Terminal Diverter to Rheem models other

than those identified above can result in a potentially unsafe condition.

SETTING BURNER GAS PRESSURE OF THE WATER HEATER

It is necessary to check the burner gas pressure at both the minimum and maximum operational settings. To

check and if necessary adjust the operational gas pressures, the electrical supply to the water heater must be

switched on, the burners ignited and hot water must be flowing from a hot tap.

Warning: The removal of the front panel will expose 240 volt wiring. Take care not to touch wiring terminals.

Note: If an 874 series model is installed as an in-series gas booster for a solar water heater, then during this

procedure the temperature of the water entering the in-series gas booster must be below 58°C. Otherwise the

gas burners will not ignite and the operational gas pressures cannot be measured.

1. Close any hot taps and ensure the burners are not operating.

2. Turn off the controller(s), if one is fitted, by pressing the on / off ( ) button and switch off the electrical

supply at the power outlet to the water heater.

3. Remove the top and bottom cover strips to gain access to the front cover screws by pressing on the two

ridged finger points and gently pulling forward.

4. Remove the screws holding the front panel to the jacket.

5. Gently disengage the front panel and pull forward to remove

from the water heater.

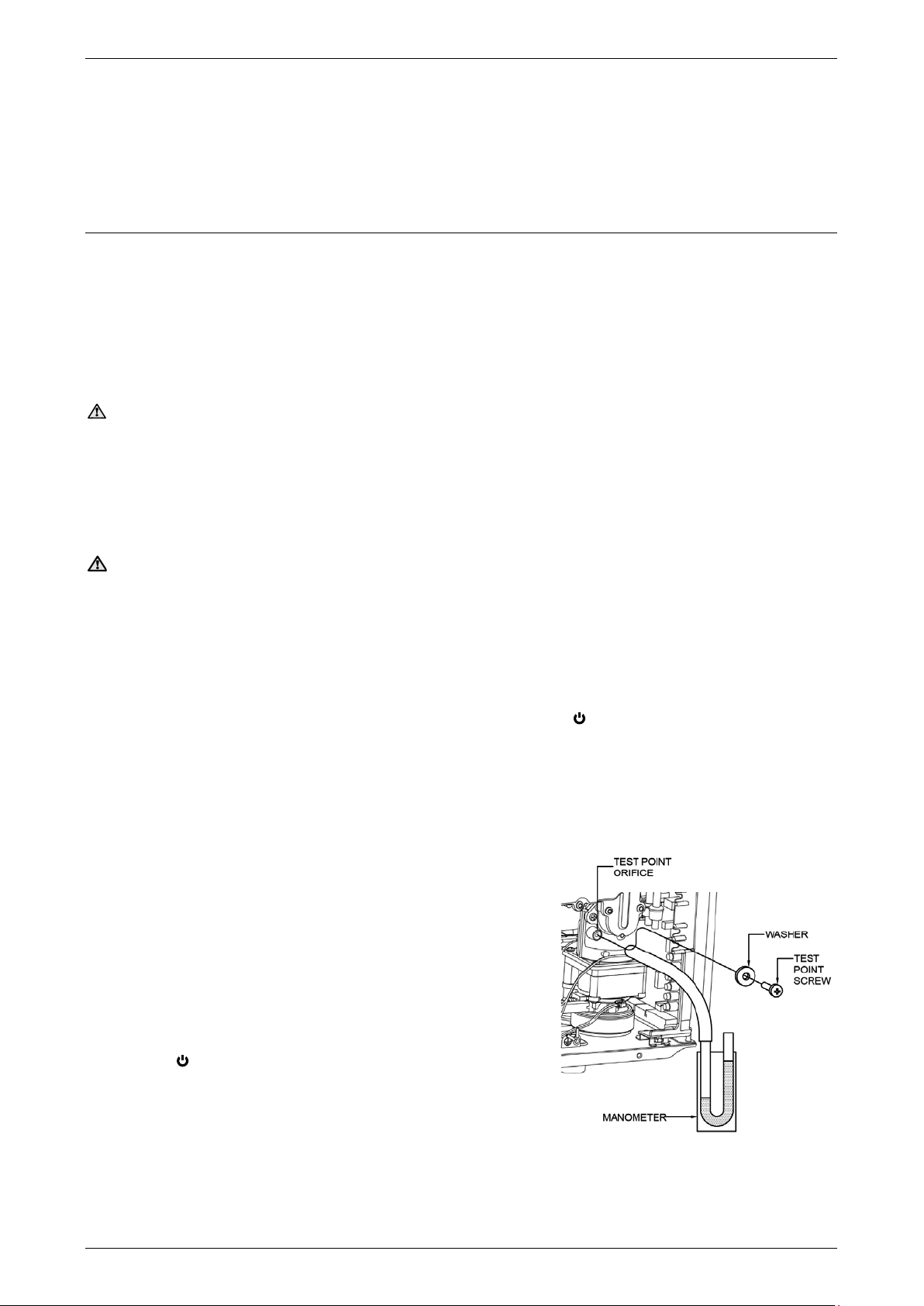

6. Locate the burner pressure test point on the main burner

manifold

Remove the test point screw and washer from the test

point orifice.

Connect the manometer.

7. Switch on the electrical supply at the power outlet to the water

heater and turn on a controller, if one is fitted, by pressing the

on / off ( ) button.

8. The priority light and the on / off operating light will both glow.

9. Open the gas isolation valve fully at the gas inlet to the water

heater, if not already open.