5

2. RECEIVING EQUIPMENT

On receipt of your equipment, it is suggested that you

visually check for external damage to the carton. If the

carton is damaged, it is suggested that a note be made

on the Bill of Lading when signing for equipment. Remove

the complete assembly from the carton. If it is damaged,

report the damage to the carrier immediately. Be sure

that you receive the number of packages indicated on the

Bill of Lading. Claims for shortages and damages must

be led with the carrier by consignee.

Purchased parts are subject to replacement only under

the manufacturer’s warranty. Debits for defective

replacement parts will not be accepted and defective parts

will be replaced in kind only per our standard warranties.

When ordering parts, you must specify the kit number.

When ordering under warranty conditions, you must also

specify the date of installation.

The manufacturer recommends that this manual be

reviewed thoroughly before installing the D-2 Power

Vent. If there are any questions which this manual does

not answer, please contact you local Representative.

THIS MANUAL SHOULD BE MAINTAINED IN LEGIBLE

CONDITION AND KEPT ADJACENT TO THE UNIT.

Included items:

(1) D-2 Power Vent

(1) Collar Adapter

(1) 7/8" Plastic Grommet

(1) Adj. 90° Elbow with Screen

(1) 4” Flue Adapter

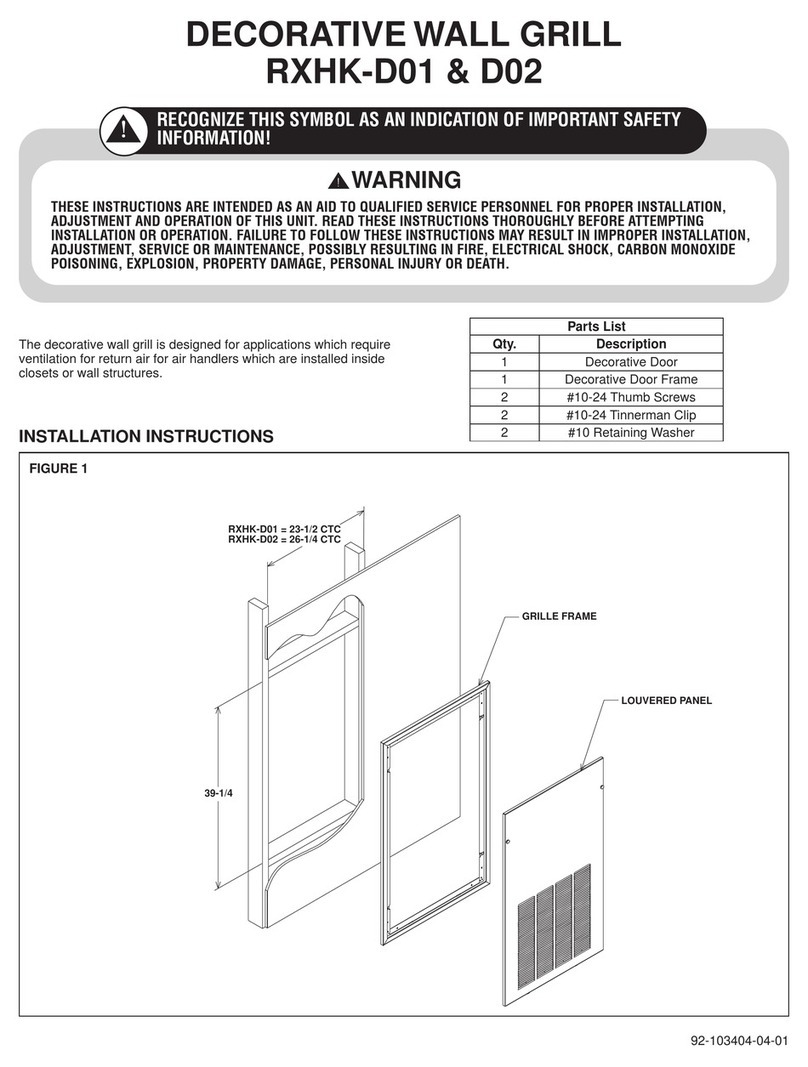

COLLAR ADAPTER

4" ADAPTER D-2 POWER VENT

(WITH ADAPTER IN PLACE)

SEPARATED

TOGETHER)

ELBOW WITH SCREEN

(VENT TERMINATION)

Figure 1. D-2 Parts

3. GENERAL

SPECIFICATIONS

The D-2 Power Vent is tested and certied to the latest

edition of the American National Standard ANSI Z21.56

standard for pool heaters.

The D-2 Power Vent is a fan-assisted combustion system

designed for application to heater models 206 thru 408.

When installed as directed, the unit is capable of operating

in applications such as through-the-wall venting and

reduced horizontal and vertical Category III ue pipe sizes

in new and existing installations.

The D-2 Power Vent includes a blower with a 120/240 volt

60Hz 1.95/1.0A 3200 RPM motor and a plenum, complete

with a draft proving switch and a motor relay.

Model No. Factory

Wired

D-2 Power Vent

Part No.

206/207 - 266/267/268 240 VAC 009832

336/337 - 406/407/408 009833

206/207 - 266/267/268 120 VAC 010744

336/337 - 406/407/408 010745

Table A. D-2 Usage and Kit Numbers

Dimensions

Refer to Figure 2.

Model Dimensional Data

AB

206/207, 266/267/268 12.31" (31.3 cm) 4.31" (10.9 cm)

336/337, 406/407/408 18.31" (46.5 cm) 7.31" (18.6 cm)

Table B. Dimensions

4. INSTALLATION

REQUIREMENTS

Failure to install, maintain and/or operate the Power Vent

in accordance with manufacturer’s instructions may result

in conditions which can produce bodily injury and property

damage.

The equipment must be installed by a qualied installer

in accordance with all local codes, or, in the absence of

local codes, with the latest edition of the National Fuel Gas

Code, ANSI Z223.1/NFPA 54 and the National Electrical

Code, ANSI/NFPA 70. In Canada, installations must

conform to CAN/CSA B149.1 and to the latest Canadian

Electrical Code Part 1.

Disconnect power supply when making wiring connections

or when working around the fan blade and motor. Failure to

do so may result in severe personal injury and equipment

damage.

Make certain the power source is adequate for the fan

motor requirements. Do not add the Power Vent to a circuit

where the total load is unknown.

APPROVED

UNCONTROLLED DOCUMENT IF PRINTED