5

2. GENERAL SAFETY

To meet commercial hot water use needs, the high-limit

safety control on this water heater is adjustable up to

210°F (99°C). However, water temperatures over 125°F

(51.7°C) can cause instant severe burns or death from

scalds. When supplying general purpose hot water, the

recommended initial setting for the temperature control is

125°F (51.7°C).

Safety and energy conservation are factors to be

considered when setting the water temperature on the

thermostat. The most energy-ecient operation will result

when the temperature setting is the lowest that satises

the needs of the application.

Water temperature over 125°F (51.7°C) can cause instant

severe burns or death from scalds. Children, disabled and

elderly are at highest risk of being scalded.

• Feel water before bathing or showering.

• Temperature limiting valves are available.

NOTE: When this water heater is supplying

general-purpose hot water for use by individuals, a

thermostatically controlled mixing valve for reducing

point-of-use water temperature is recommended to

reduce the risk of scald injury. Contact a licensed plumber

or the local plumbing authority for further information.

Maximum water temperatures occur just after the

heater’s burner(s) have shut-o. To determine the water

temperature being delivered, turn on a hot water faucet

and place a thermometer in the hot water stream and read

the thermometer.

Water temperature over 125°F can

cause instant severe burns or death

from scalds.

Children, disabled, and elderly are

at highest risk of being scalded.

See instruction manual before set-

ting temperature at water heater.

Feel water before bathing or show-

ering.

Temperature limiting valves are

available, see manual.

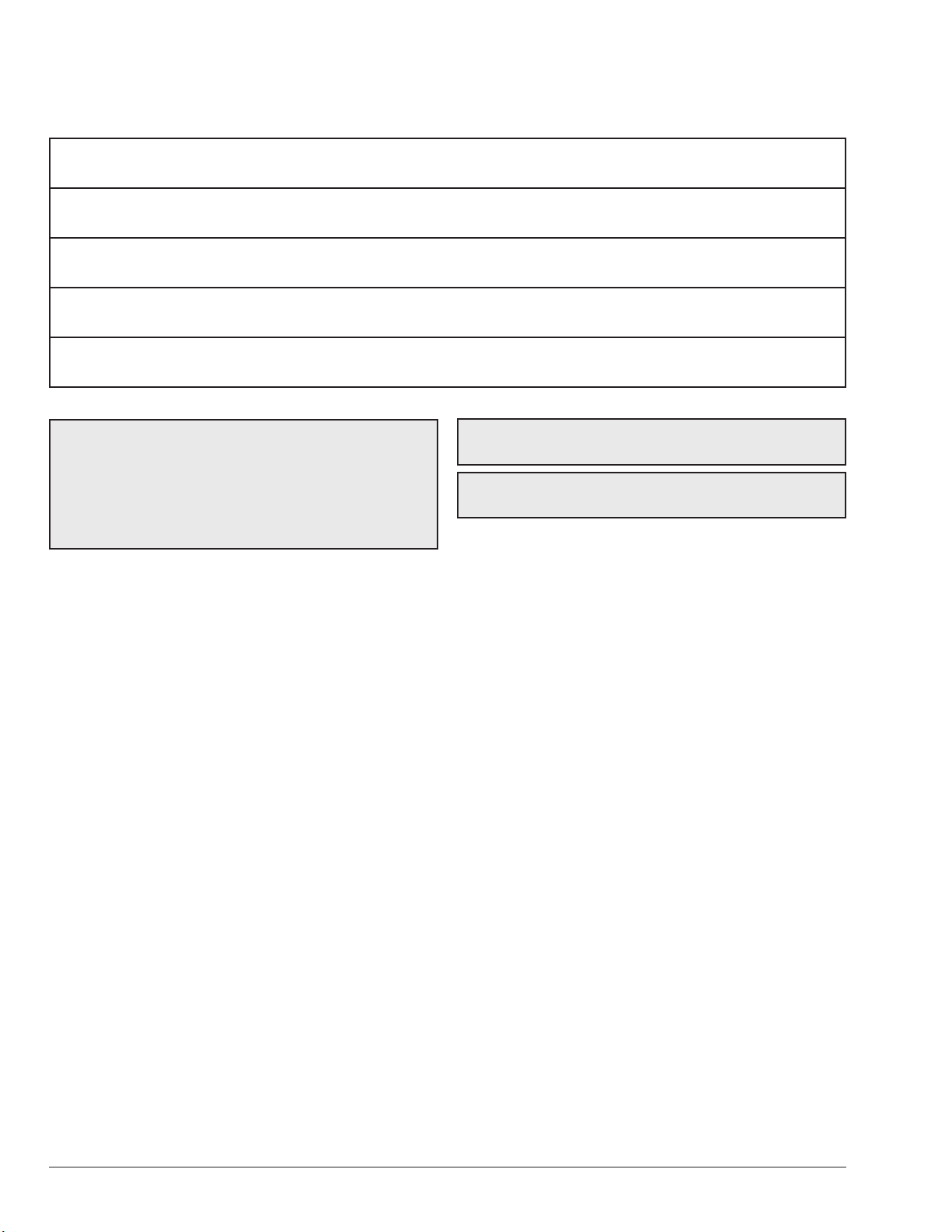

Time/Temperature Relationships in

Scalds

The following chart details the relationship of water

temperature and time with regard to scald injury and

may be used as a guide in determining the safest water

temperature for your applications.

Water Temp. Time to Produce Serious Burns

120ºF (48.9°C) More than 5-Minutes

125ºF (51.7°C) 1-1/2 to 2-Minutes

130ºF (54.4°C) About 30-Seconds

135ºF (57.2°C) About 10-Seconds

140ºF (60.0°C) About 5-Seconds

145ºF (62.8°C) About 3-Seconds

150ºF (65.6°C) About 1-1/2-Seconds

155ºF (68.3°C) About 1-Second

Table courtesy of the Shriner's Burn Institute

Table A. Time to Produce Serious Burn

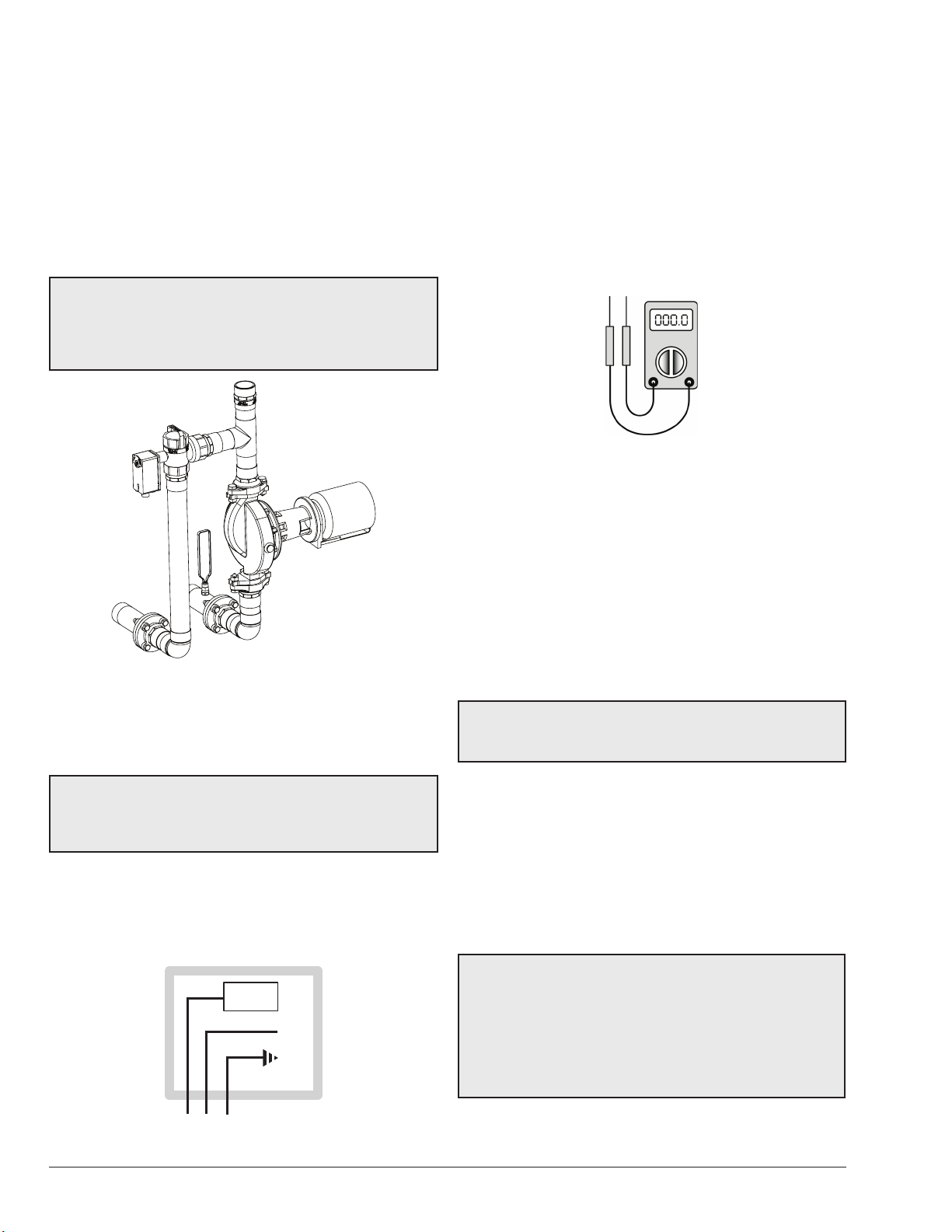

3. COLD WATER START

It is commonly known that prolonged internal condensation

will dramatically shorten the life of standard eciency

boilers. While Raypak boilers can operate without harmful

condensation at lower inlet water temperatures than the

competition, there are still applications that require reliable

protection against harmful condensation caused by

frequent, extended, cold water start-ups. Raypak's Cold

Water Start protection system utilizes a proportional three-

way valve to bypass water from the boiler outlet to the inlet

during start-up, when the system return water temperature

is below the minimum acceptable level.

This approach:

• continuously monitors and adjusts inlet water

temperature to prevent condensation.

• regulates the minimum inlet water temperature

during system start-up.

• activates an alarm and/or shuts down the boiler if the

minimum inlet water temperature is not achieved.

• eliminates jobsite setup with proprietary self-tuning

controller and system-matched components.

• allows high-temperature system operation without

cycling on the high-limit.

ACAUTION: The Cold Water Start package is ONLY

supported for closed-loop hydronic applications. Do not

use for domestic hot water systems, or pool systems.