Page 8 of 8

Important information:

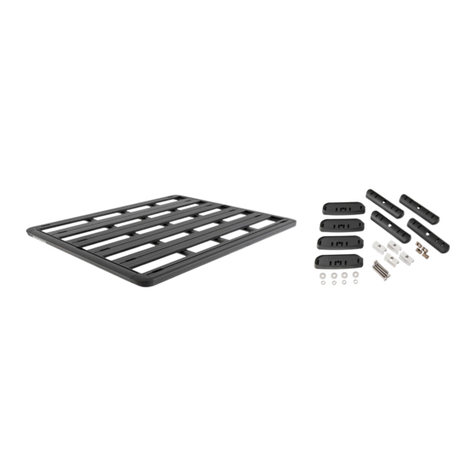

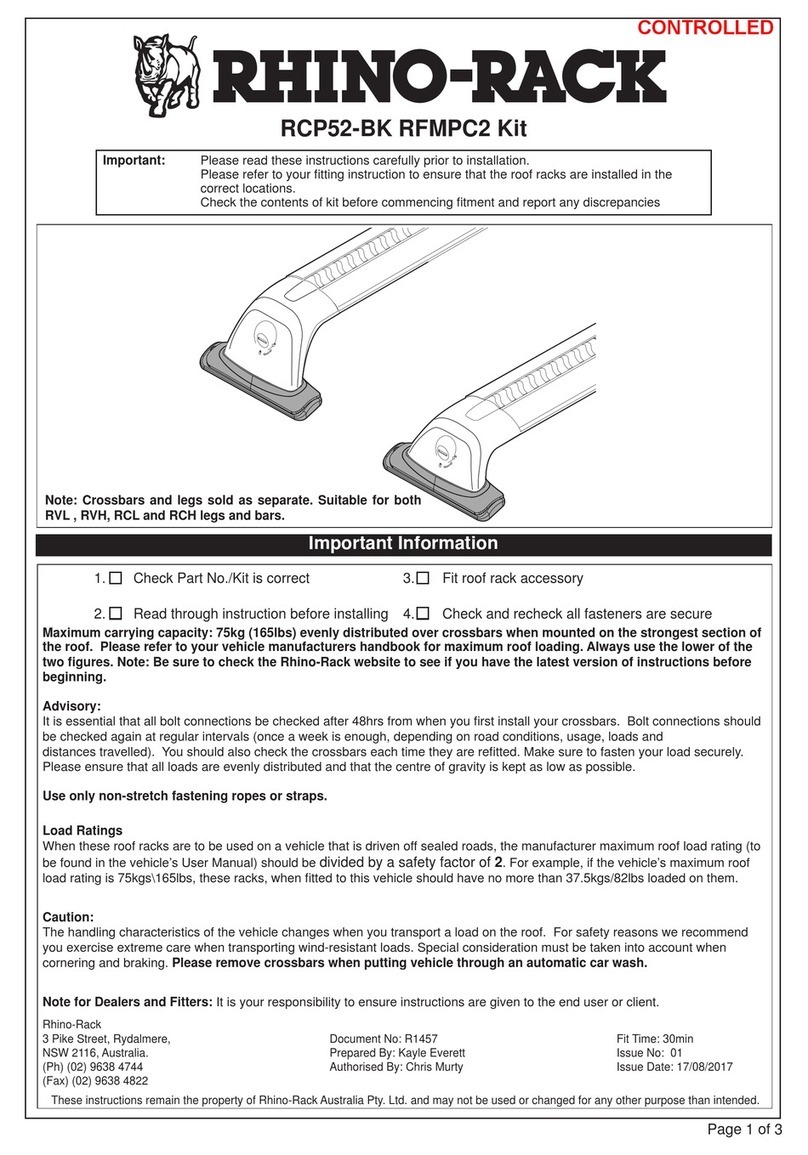

Maximum carrying capacity –3 crossbars 150Kgs.

Removing the Crossbar Assembly:

Insert the security Allen key into the head of the M6 security screw and remove the screw. The mounting pads can remain

attached to the vehicle. Install cover plates onto the mounting pads using the M6 crossbar attachment screws. Do not

remove the mounting legs from the crossbars. Store crossbars and hardware in a safe place.

Refitting the crossbar assembly:

To refit the crossbar assemblies, place the crossbars onto the mounting pads in their preset positions. Insert the M6 screw

assemblies as per the instructions, using the security Allen key tighten the screw as recommended in instructions.

Important Information:

Recommendations.

Please refer to the vehicle manufactures operating manual for the maximum roof load rating.

It is essential that all bolts and screws connections are checked after driving a short distance when first install your Rhino-

Rack crossbars. Bolt and screw connections should be rechecked again at regular intervals (probably once a week is

enough depending on road conditions, usage, load and distances traveled). You should also check the crossbars each time

they are refitted.

Crossbars and accessories should be cleaned and all screw threads lubricated at regular intervals.

Rhino-Rack offers a lifetime warranty to the original purchaser of the Rhino-Rack roof rack system and accessories.

Rhino-Rack cannot be held responsible for incorrect mounting of the roof rack system or for usage that exceeds vehicle and

production tolerances.

Make sure to fasten your load securely. Please ensure that all loads are evenly distributed and that the centre of gravity is

kept as low as possible, use only non-stretch fastening ropes and straps.

SENSITIVITY TO CROSSWINDS, BEHAVIOUR IN CURVES AND BRAKING:

The handling characteristics of the vehicle change when you transport a load on the roof. For safety reasons we

recommend you exercise extreme care when transporting wind resisting loads. Special consideration must be taken into

account when braking.

PLEASE REMOVE CROSSBARS WHEN PUTTING THE VEHICLE THROUGH AN AUTOMATIC CAR WASH.

LOAD RATINGS:

The vehicle manufactures recommended load rating is the maximum permissible load per pair of bars ( include the weight

of the roof racks 5Kg). When roof bars are to be used in extreme off-road conditions, build a safety factor 1.5 into this

maximum load limit. Although the roof racks are tested and approved to AS1235-2000, Australian road conditions can be

much more rigorous.

NOTE FOR FITTERS AND DELALERS:

It is your responsibility to ensure instructions are give to the end user or client.

Rhino-Rack

3 Pike Street, Rydalmere, Document No: RR167

NSW, 2116, Australia. Prepared By: Alan Marshall. Issue: 03

(Ph) +61 2 9638 4744 (Fax) +61 2 9638 4822. Authorised By: Chris Murty. Issue date: 27/03/2013.

These instructions remain the property of Rhino-Rack Australia Pty Ltd and may not be used or changed for any other purpose than intended.