Pag. 23 di 36 E

N

G

L

I

S

H

GRADUAL START

Upon gate operation command, a gradual start is performed, as default, for 1 sec.

ELECTRONIC BRAKE

In case the slowing mode is not used (dip 8 ON), enabling of dip 7 (ON) is recommended.

In this way the electronic brake will cope for the gate inertia on approach of the travel stop

switches.

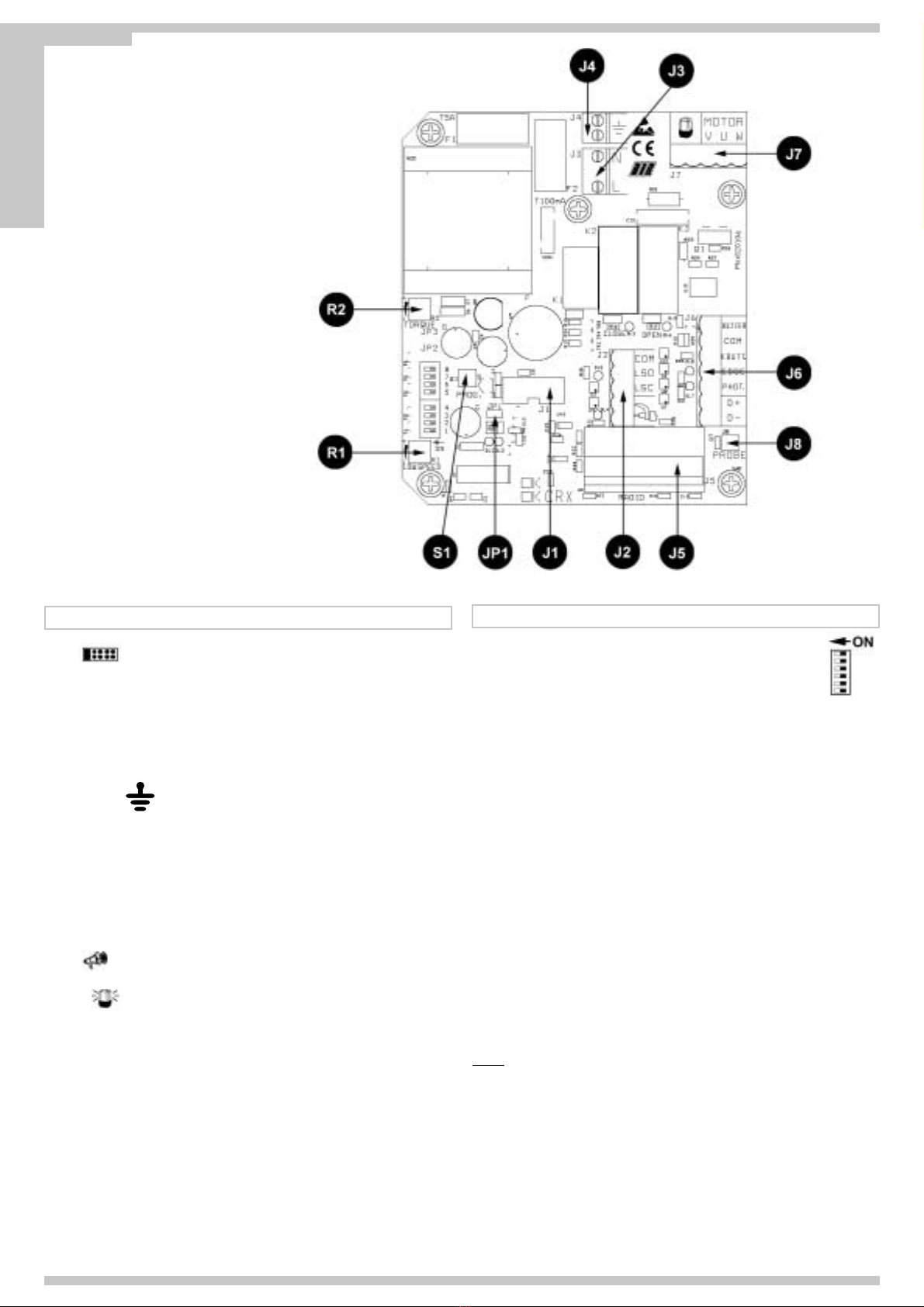

LED SIGNALS

DL1 - (Red) - Programming operated

DL2 - (Green) - Radio programming activated (models CRX only)

DL3 - (Red) - Opening limit switch contact (NC)

DL4 - (Red) - Closing limit switch contact(NC)

DL5 - (Red) - Gate on closure

DL6 - (Green) - Gate on opening

DL7 - (Red) - Photocells contact (NC)

DL8 - (Red) - afety strips contact (NC)

C – CHECKING THE ROTATION DIRECTION OF THE MOTOR

This control is carried out to facilitate the installation of the system or any possible future

control.

1 - After you have ensured the correct positioning of the limit switch (fig.7) manually move

the gate to half open position;

2 - Put DIP 1 in the ON mo e => The LED DL1 starts blinking;

3 - Press the PROG button and hold it (the gate now is controlled in a dead man mode:

open, stop close stop open-etc...) => THE RED LED DL5 "CLOSE" comes on an

the gate starts closing (if it does not close, invert the wires of the motor V and W)

until it reaches the limit switch of the close position (if the gate and motor do not stop,

release the PROG button and invert the position of the cables L O and L C);

4 - Press the PROG button and hold it => THE GREEN LED DL6 "OPEN" comes on

an the gate opens until it reaches the limit switch for opening position;

5 - After 2 sec. an within 10 sec. of continuous work, both in closing or opening,

the electronic clutch intervenes automatically. A just the force of the clutch by

turning the appropriate trimmer “TORQUE”.

6 - After 10 sec. of continuous work, both in opening an closing, the automatic

eceleration is activate (if DIP 8 is on OFF position) A just the spee of the

operator requeste uring the eceleration by turning the appropriate trimmer

“LOW SPEED”.

7 - At the en of the control, an of the trimmers’ a justements, position DIP1 on

mo e OFF. The LED DL1 turns off, signalling you exit from the control.

NB: The safety edges and the photocells are not active during this control.

D - TIMING

The programming can be carried out regardless of the gate position.

1 - Put DIP 2 in the ON mode => the LED DL1 emits short blinkings.

2 - Push the button PROG. => the gate opens closes and opens automatically 2 seconds

after It closed. When the opening cycle Is terminated, It stops. Wait as long as you

want the gate to remain open (excluded by DIP3 OFF)

3 - Push the button PROG. to command the gate closing (also the pause time count

before the automatic closing stops - max. 5 minutes).

4 - The gate stops as the closing limit switch is reached.

5 - AT THE END OF THE PROGRAMMING PUT THE DIP 2 BACK ON OFF.

DURING THE PROGRAMMING THE SAFETIES ARE ACTIVE AND THEIR

INTERVENTION STOPS THE PROGRAMMING (THE LED DL2 WHICH WAS

LIGHTENING NOW HAS A COSTANT LIGHT). TO REPEAT THE PROGRAMMING

SET THE DIP 2 ON OFF AND REPEAT THE PROGRAMMING DESCRIBED ABOVE.

NOTE: The deceleration speed is set automatically by the control panel during the time

programming. The deceleration starts automatically about 15-20 cm before the

gate reaches the limit switch in opening and closing.

E – RADIO CODE LEARNING PROCEDURE

(CRX MODELS ONLY)

1 - The position of the gate does not affetc the code memorisation.

PLEASE NOTE: if DIP3 is in ON position (pause time before automatic closing)the code

memorisation cannot be carried out with the gate in completely open

position.

2 - et DIP 1 - ON and subsequently DIP 2 - ON => DL1 programming led will lighten with

a frequency of 1 sec. ON e 1 sec. OFF for 10 seconds, witch is the time required for

they code’s programming.

3 - Press the remote control button (normally the A channel) within the 10 set seconds. If

the remote control is correctly read in, the DL2 green led emits a flashing.

4 - The codes’ programming time is automatically renewed to read in the following remote

control.

5 - To end the programming wait 10 seconds, or press for a while the PROG. button =>

DL1 programming led will stop lightening.

6 - Re-set DIP 1 - OFF and DIP 2 - OFF.

7 - End of the procedure.

RADIO CODES CANCELLATION PROCEDURE

The position of the gate does not affetc the code memorisation.

PLEASE NOTE: if DIP3 is in ON position (pause time before automatic closing) the code

memorisation cannot be carried out with the gate in completely open

position.

1 - et DIP 1 - ON and subsequently DIP2 - ON.

2 - DL1 programming led will lighten with a frequency of 1 sec. ON and 1 sec. OFF for 10

seconds.

3 - During the 10 seconds => press and keep pressed the PROG. Button for 5 seconds

=> the memory cancellation is signalled by two flashings of the DL2 green Led.

4 - ubsequently DL1 programming led stays active and it is possible to add new codes

following the procedures described above.

MEMORY SATURATION SIGNALING

The position of the gate does not affetc the code memorisation.

PLEASE NOTE: if DIP3 is in ON position (pause time before automatic closing)the code

memorisation cannot be carried out with the gate in completely open

position.

1 - By setting DIP 1 - ON and subsequently DIP 2 -ON.

2 - DL2 green Led lightens for 6 times thus signalling that the memory is full (60 codes

available).

3 - ubsequently the DL1 programming led stays active for 10 seconds, thus enabling the

possible total cancellation of the codes.

OPERATION OF THE OPERATING ACCESSORIES

OPERATION BUTTON (COM-K BUTTON)

If DIP6 is ON => It cyclically commands open-stop-close-stop-open-etc.

If DIP6 is OFF => It opens the gate when this is closed. If it is operated while the gate Is

opening, it has no effect.

If it is operated when the gate is open, it closes the gate and, if it is operated while the

gate is closing, it opens the gate again.

TIMER FUNCTION (automatic operation mo e only DIP 6 OFF)

This function is useful In the rush hours, when vehicle traffic is slow (e.g. entry/exit of

workers, emergencies In residential or parking areas and, temporary, for removals).

APPLICATIONS

By connecting a switch and/or a daily/weekly timer (in place or in parallel with the opening

button N.O. “COM-K BUTTON”), it is possible to open the gate or to keep it open, as long

as the switch is on or the timer is activated.

When the gate is open, all operating functions are inhibited.

On switch release, or at set time, the actuator will close.

RADIO TRANSMITTER

If DIP6 is ON => It cyclically commands open-stop-close-stop-open-etc.

If DIP6 is OFF => It opens the gate when this is closed.

If it is operated while the gate is opening, it has no effect.

If it is operated when the gate is open, it closes. If it is operated while the gate is closing, it

opens the gate again.

AUTOMATIC CLOSING FOR COMPLETE OPENING

The pausing time before the automatic closing for complete opening is set during the time

programming. The maximum pausing time available is 5 minutes. Pause time can be

started or stopped by DIP3 (ON started).

RESTORING OF OPERATION FOLLOWING A BLACK OUT FAILURE

Following a black out, and on resuming of power supply, the gate will operate as indicated

on table TAB1, at the following page.