2

F-Series Remote Displays Installation Manual

2.0 Pre-Installation Setup

The F-Series remote displays should be set up,

configured, and tested before delivery to the

installation site.

This section describes RS-232 and 20 mA current

loop indicator connections. Once pre-installation

setup is complete, go to Section 3.0 for information

about configuring the remote display.

Use a wrist strap to ground yourself and

protect components from electrostatic

discharge (ESD) when handling chips

and working inside the remote display

enclosure.

2.1 Indicator Connections

To connect the communications cable to the remote

display, do the following:

1. Disconnect power and open the remote

display enclosure.

2. For Models F40 and F60, turn the retaining

screws and lower the hinged flip digit

mounting panel. For the Model F15, remove

the two screws from the hinged flip digit

mounting panel, then lower the panel.

3. Loosen the serial cable cord grip and push

only enough communications cable into the

enclosure to allow attachment at the terminal

block.

4. Strip 1/4 inch (.65 cm) of insulation from the

serial cable ends.

5. Make cable connections for RS-232 or 20 mA

current loop communications as described in

Sections 2.1.1 or 2.1.2, below.

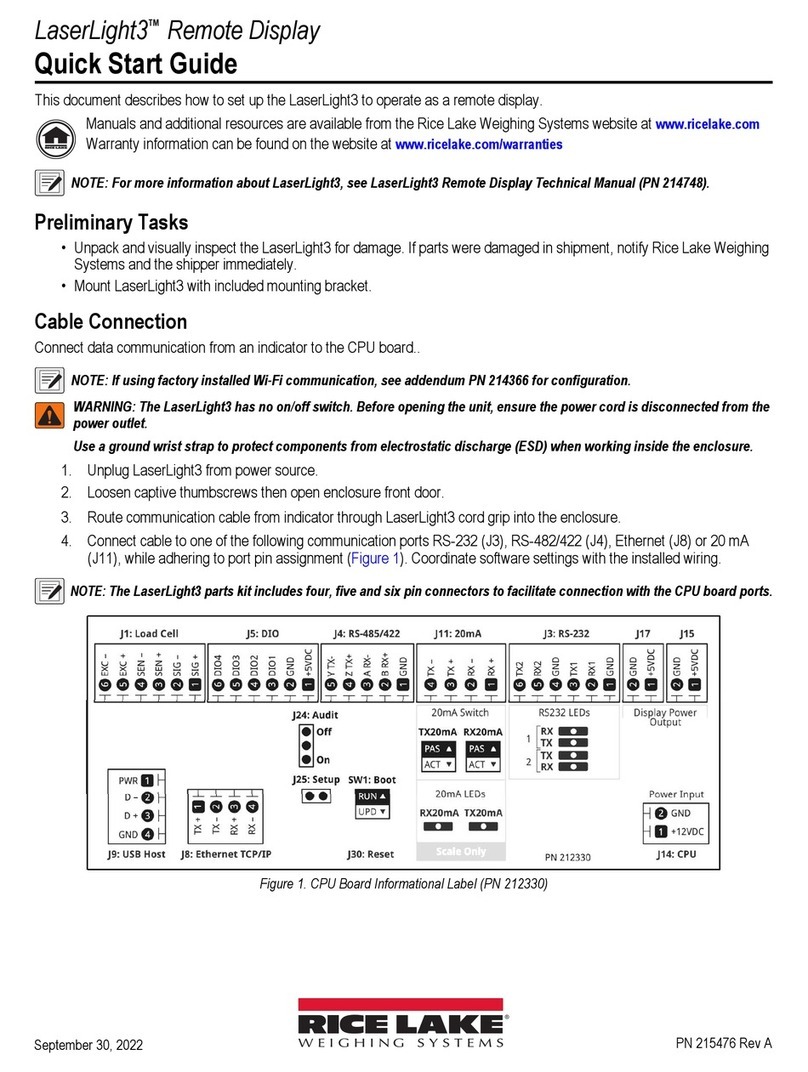

6. For RS-232 connections, remove jumper

JMP1 on the CPU board (see Figure 2-1).

7. Remove any excess cable from inside the

enclosure, then tighten the serial cable cord

grip.

The DIP switches on the remote display CPU board

should be set and the remote display configuration

verified before sealing the display enclosure. DIP

switch configuration is described in Section 3.0.

A loop-back self-test can be used to test the function

of the remote display serial port. See Section 5.3 on

page 14 for information about the loop-back self-test.

2.1.1 RS-232

Figure 2-2 on page 3 shows the connections required

for RS-232 communications to the remote display.

See the manual for your indicator to determine the

indicator pin assignments for RS-232

communications.

2.1.2 20 mA Current Loop

Figures 2-3 and 2-4 show the connections required for

passive or active 20 mA current loop communications

to the remote display. See the manual for your

indicator to determine the indicator pin assignments

for 20 mA communications.

Figure 2-1. Locations of Jumper JMP1 and 20 mA Chips on

Left Edge of CPU Board

Caution

J1

POWER INPUT

+15

+5

GND

GND

J3

JMP1

20mA/RxD

U9

U14

20 mA TxD

20 mA RxD

15V pull-up

5V pull-up

+

+ +

RS-232

42004100

Jumper JMP1:

Remove for RS-232,

leave on for 20 mA

20 mA chips:

4200 chip in socket U9

4100 chip in socket U14