Installation Overview 1

Introduction

This manual is intended for use by technicians

responsible for installing and servicing the

SURVIVOR®ATV Series portable truck scale. The

ATV truck scale has been designed to significantly

reduce installation time. A well-organized,

experienced installation crew should be able to install

a typical three module 70' x 11' ATV truck scale in

less than 4 hours. This estimated time may vary.

NOTE: This booklet covers ATV portable truck scale

installations. Use these instructions as general installation

guidelines unless the engineering drawings furnished with

your scale differ from the instruction in this booklet.

Engineering drawings furnished with your scale always take

priority over these general installation guidelines.

Refer to the engineering drawings furnished with the scale for all

component numbering sequences.

Authorized distributors and their

employees can view or download this

manual from the Rice Lake Weighing Systems

distributor site at www.ricelake.com.

Package includes: Bolt-on backfill ramp bulkheads

(removable for concrete approaches); assembled

weighbridge modules and weighbridge fasteners; load cells

with conduit fitting; load cell mounts; copper transient

bypass cables at each load cell; metal conduit on

weighbridge for load cell cable runs; flexible conduit from

load cell to metal conduit; conduit fittings for flexible to

metal conduit; polycarbonate junction box(es); homerun

cable to indicator (60'long) and print packages including

installation manual.

Package does not include: peripherals; freight charges

including material handling/crane; transportation

permits and fees; escort(s) charge; or insurance

transportation fees.

1.0 Installation Overview

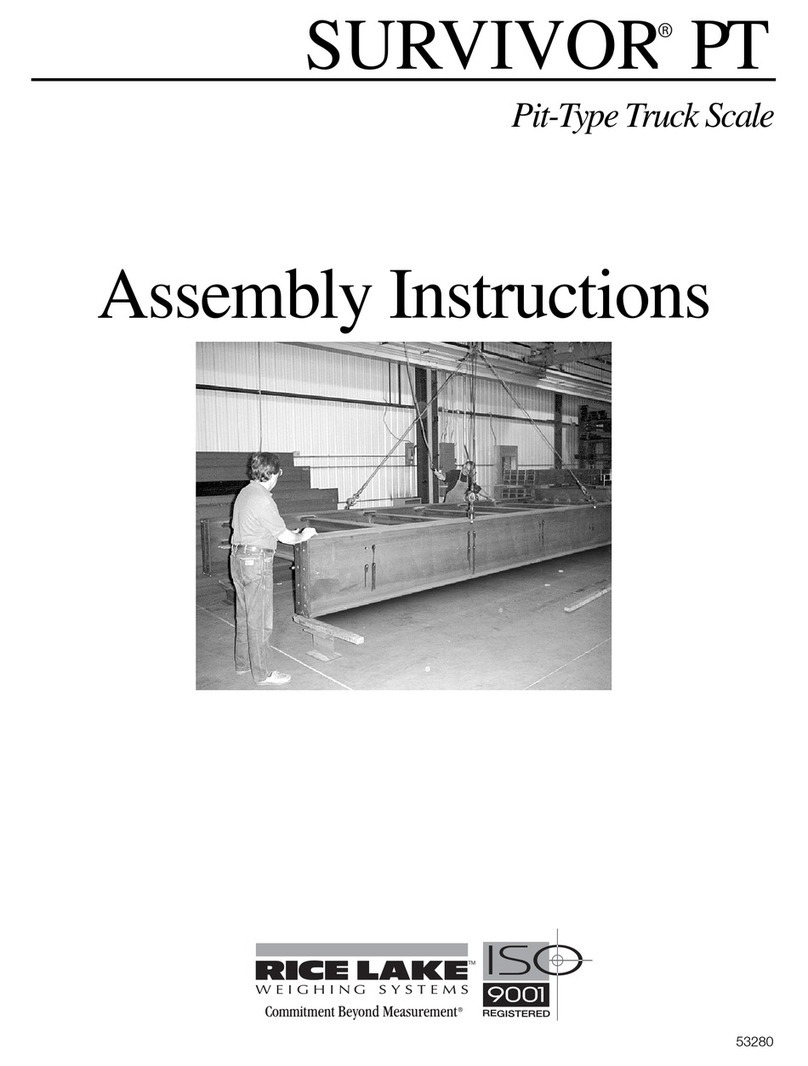

The modular sections of the ATV truck scale are shipped pre-assembled and ready to be placed on a flat surface

using a crane. The self-contained modules are positioned on a prepared and level site. The weighbridge is

lowered onto the load cells by retracting the shipping stands.

The indicator is connected to one of the two junction boxes (J-boxes). That J-box is then connected to the other

J-box via an expansion cable.

You can then back fill material to bulkheads and calibrate to finish the installation.

General Assembly Order

1. Based on location of the indicator, place the first self-contained module into position on level compacted

ground or other flat surface. Asphalt is not recommended.

Note: Be sure to arrange module with the J-box positioned toward the indicator.

2. Install spacer tubes and set the other self-contained module.

3. Place center (bridge module) between end modules.

4. Retract shipping stands.

5. Back fill material.