K-1000 Rodder

Ridge Tool Company2

General Safety Information

WARNING! Read and understand all instructions. Failure

to follow all instructions listed below may

result in fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS!

Work Area Safety

•Keep your work area clean and well lit. Cluttered

benches and dark areas invite accidents.

•Do not operate power tools in explosive atmo-

spheres, such as in the presence of flammable

liquids, gases, or dust. Tools create sparks which

may ignite the dust or fumes.

•Keep bystanders, children, and visitors away while

operating a tool. Distractions can cause you to lose

control.

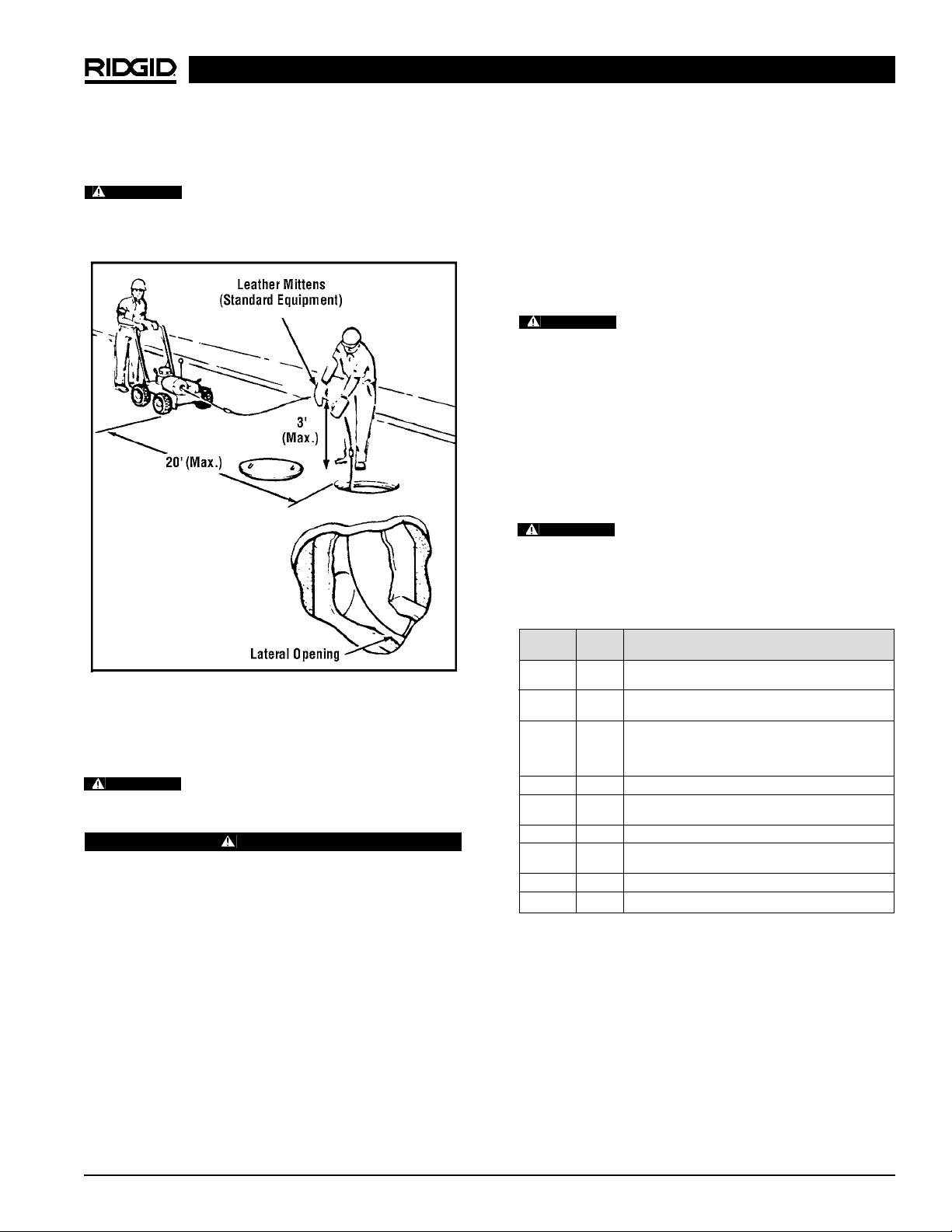

•Keep the engine at least one meter (3 feet) away

from buildings and other equipment during oper-

ation. Do not place flammable objects close to

engine. Procedures should be followed to prevent fire

hazards and to provide adequate ventilation.

Personal Safety

•Stay alert, watch what you are doing and use com-

mon sense when operating a power tool. Do not

use tool while tired or under the influence of drugs,

alcohol, or medications. A moment of inattention

while operating power tools may result in serious per-

sonal injury.

•Dress properly. Do not wear loose clothing or jew-

elry. Contain long hair. Keep your hair, clothing, and

gloves away from moving parts. Loose clothes, jew-

elry, or long hair can be caught in moving parts.

•Remove adjusting keys before turning the tool

ON. A wrench or a key that is left attached to a rotating

part of the tool may result in personal injury.

•Do not over-reach. Keep proper footing and bal-

ance at all times. Proper footing and balance enables

better control of the tool in unexpected situations.

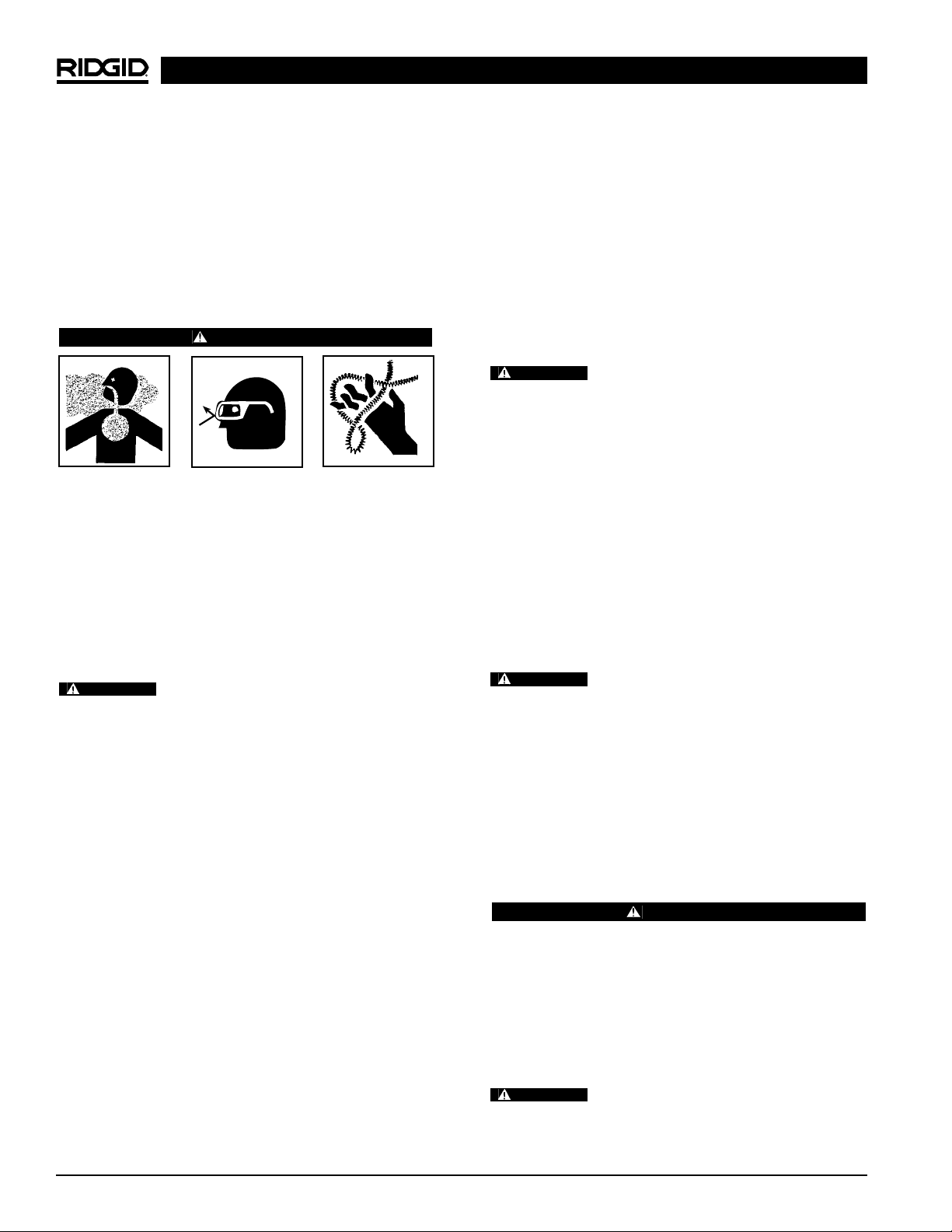

•Use safety equipment. Always wear eye protection.

Dust mask, non-skid safety shoes, hard hat, or hear-

ing protection must be used for appropriate conditions.

Tool Use and Care

•Do not force tool. Use the correct tool for your

application. The correct tool will do the job better and

safer at the rate for which it is designed.

•Store idle tools out of the reach of children and

other untrained persons. Tools are dangerous in

the hands of untrained users.

•Maintain tools with care. Keep cutting tools sharp

and clean. Properly maintained tools with sharp cutting

edges are less likely to bind and are easier to control.

•Check for misalignment or binding of moving parts,

breakage of parts, and any other condition that

may affect the tools operation. If damaged, have the

tool serviced before using. Many accidents are

caused by poorly maintained tools.

•Use only accessories that are recommended by the

manufacturer for your tool. Accessories that may

be suitable for one tool may become hazardous when

used on another tool.

•Keep handles dry and clean; free from oil and

grease. Allows for better control of the tool.

Service

•Tool service must be performed only by qualified

repair personnel. Service or maintenance performed

by unqualified repair personnel could result in injury.

•When servicing a tool, use only identical replace-

ment parts. Follow instructions in the Maintenance

Section of this manual. Use of unauthorized parts or

failure to follow maintenance instructions may create a

risk of injury.

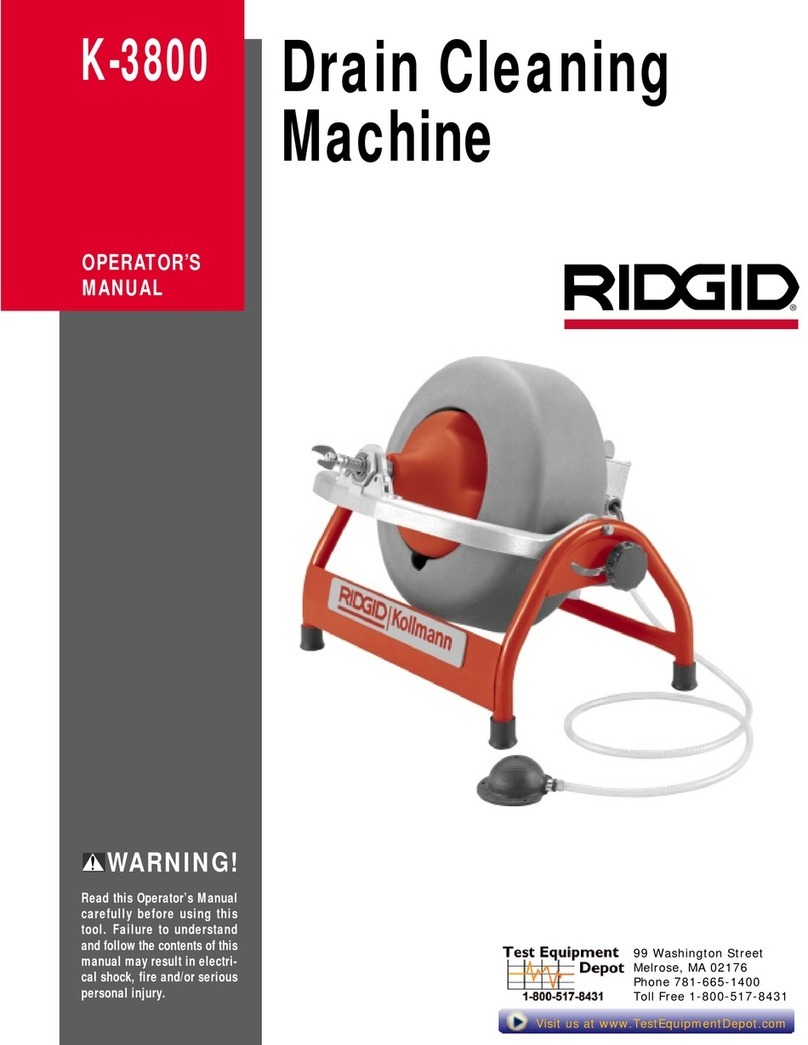

Specific Safety Information

WARNING

Read this operator’s manual carefully before using

the RIDGID K-1000 Rodder. Failure to understand

and follow the contents of this manual may result

in fire and/or serious personal injury.

Call the Ridge Tool Company, Technical Service Depart-

ment at (800) 519-3456 if you have any questions.

Machine Safety

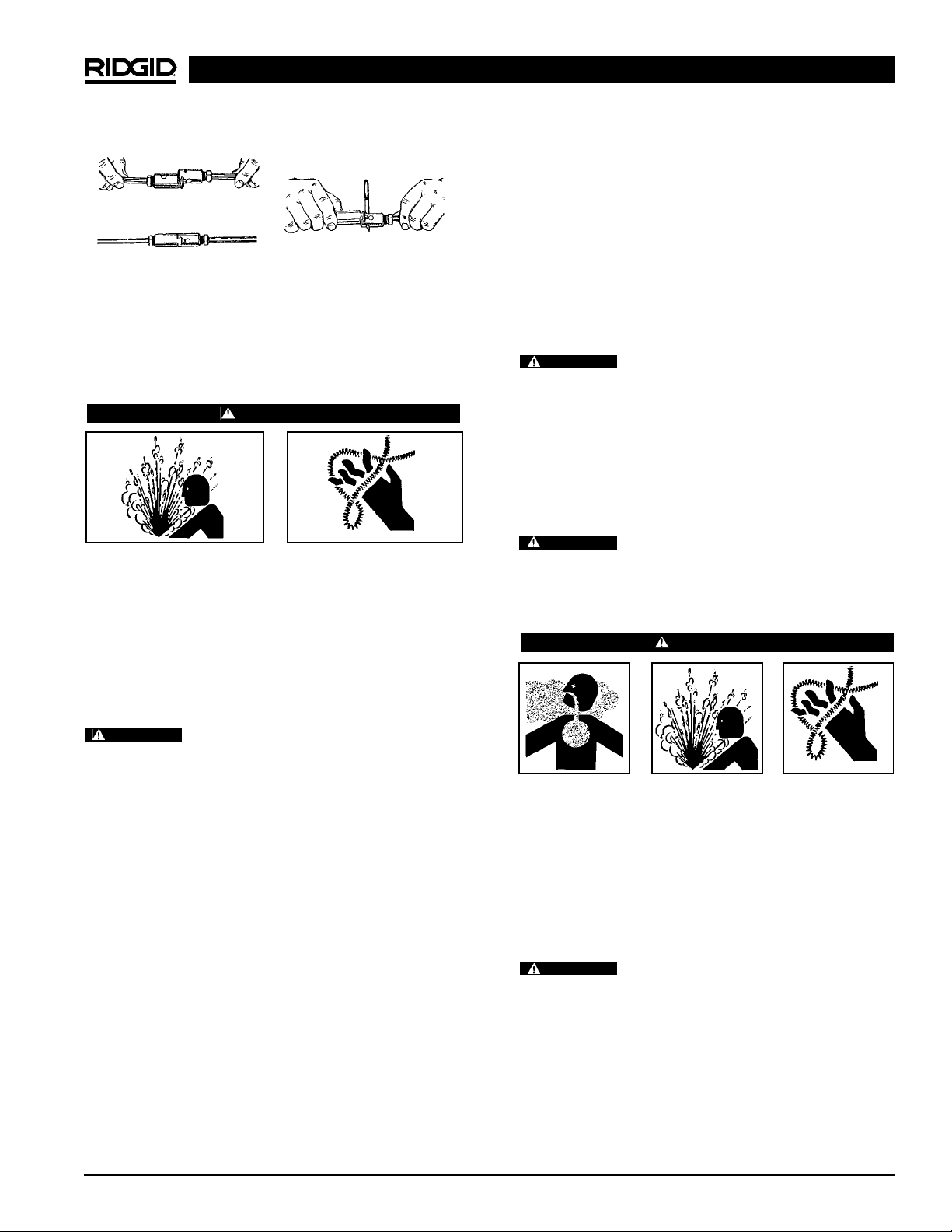

•Wear leather gloves provided with the machine.

Never grasp a rotating rod with a rag or loose fitting

cloth glove. Could become wrapped around the rod

and cause serious injury.

•Wear safety glasses and rubber soled, non-slip

shoes. Use of this safety equipment may prevent se-

rious injury.

•Never operate machine with guards removed.

Fingers can be caught between the chain sprocket.

•Do not operate machine in (REV) reverse. Operating