RIEJU MRX-SMX 50 Instruction manual

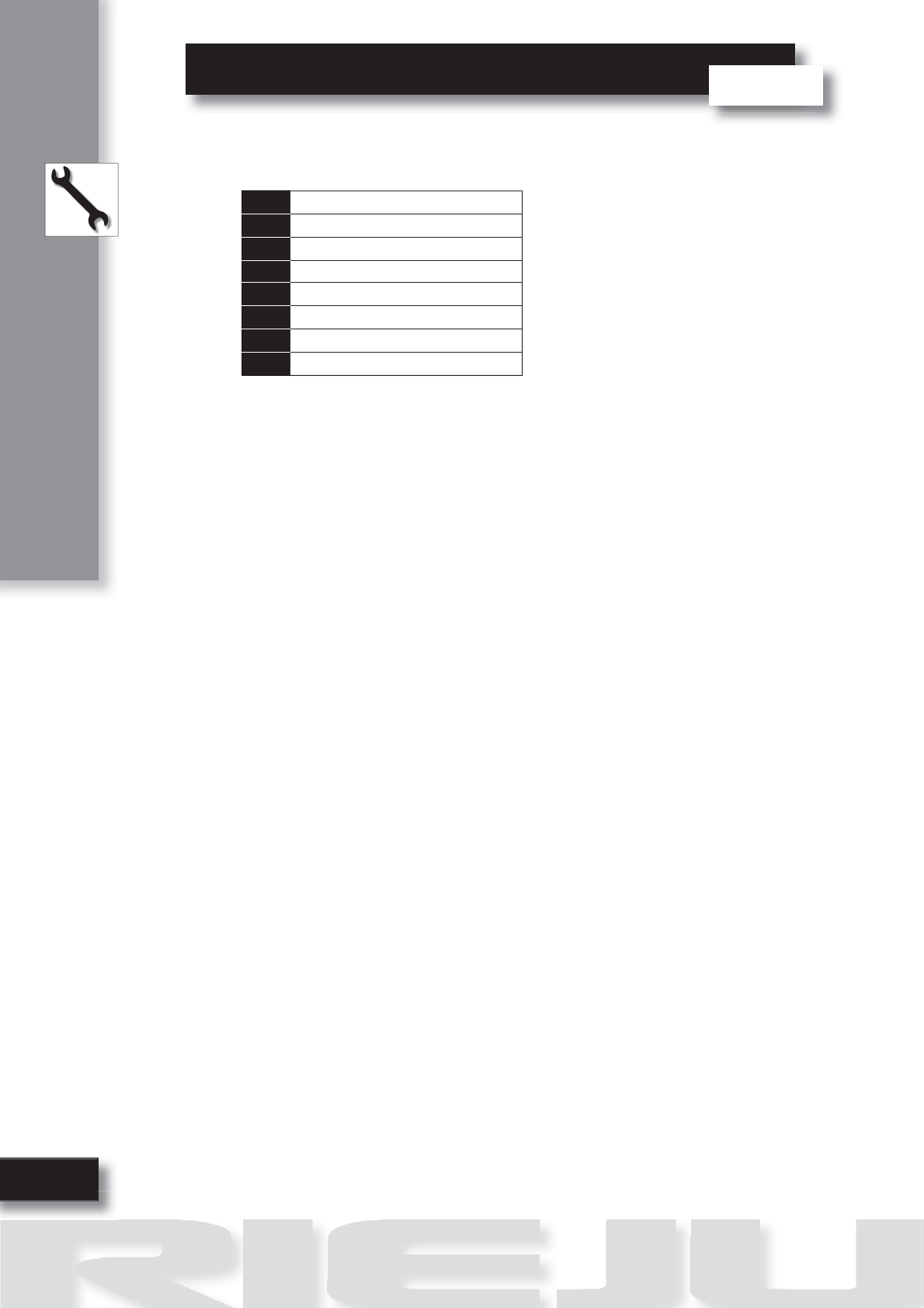

Other RIEJU Motorcycle manuals

RIEJU

RIEJU TANGO 125 User manual

RIEJU

RIEJU MRT 50 Instruction manual

RIEJU

RIEJU Tango 125 E4 User manual

RIEJU

RIEJU MR 300 User manual

RIEJU

RIEJU RS3 50 User manual

RIEJU

RIEJU Marathon 125 PRO User manual

RIEJU

RIEJU MRT 50 EURO 4 User manual

RIEJU

RIEJU Marathon 125 PRO User manual

RIEJU

RIEJU MRT 50 EURO 5 User manual

RIEJU

RIEJU MRT 125 LC User manual

RIEJU

RIEJU Strada 125 ie User manual

RIEJU

RIEJU KOSO User manual

RIEJU

RIEJU MARATHON 250 User manual

RIEJU

RIEJU tango 50 User manual

RIEJU

RIEJU MRT 50 User manual

RIEJU

RIEJU MARATHON 125 AC User manual

RIEJU

RIEJU CENTURY 125IE User manual

RIEJU

RIEJU TANGO 250 Instruction manual

RIEJU

RIEJU RS3 Naked 50 User manual

RIEJU

RIEJU MRX 125 User manual

Popular Motorcycle manuals by other brands

MV Agusta

MV Agusta Brutale 675 Workshop manual

APRILIA

APRILIA RSV MILLE - PART 1 1999 User manual content

Royal Enfield

Royal Enfield Himalayan 2018 owner's manual

SSR Motorsports

SSR Motorsports Lazer5 owner's manual

MOTO GUZZI

MOTO GUZZI 2005 Griso 1100 Use and maintenance book

KTM

KTM 85 SX 19/16 owner's manual